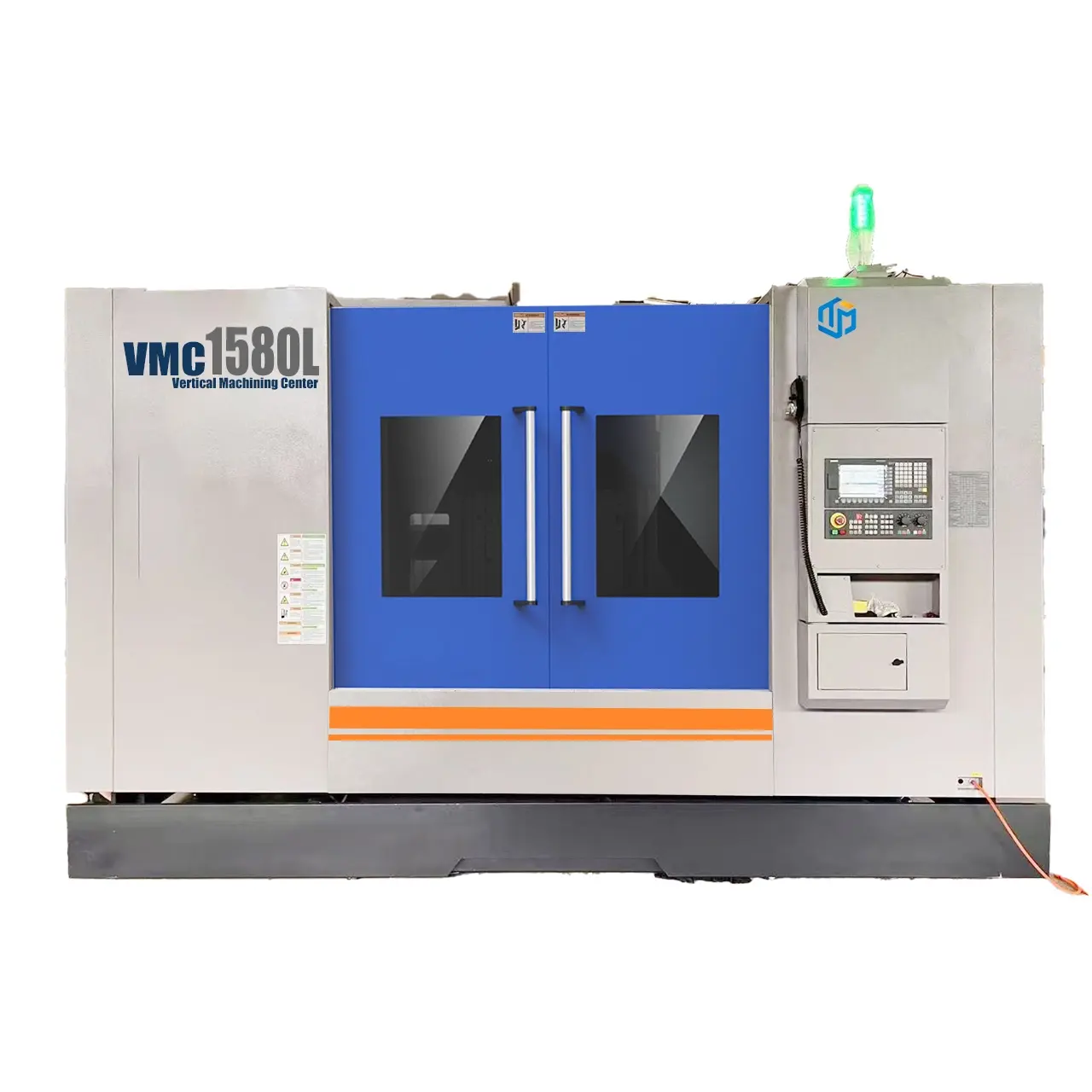

The 4-axis CNC machining center VMC1580L is developed in line with advanced international design criteria, ensuring compliance with high global industry standards.

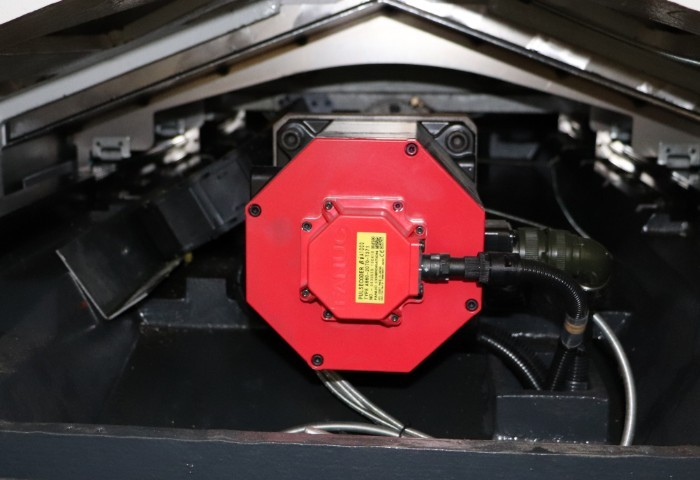

In addition, it adopts a contemporary structural design and is outfitted with premium-grade components and spare parts, laying a solid foundation for stable operation.

Thanks to these strengths, it delivers excellent performance in both the machining of precision parts and mold processing scenarios, meeting diverse high-demand manufacturing needs.

Consequently, VMC1580L not only offers outstanding operational performance but also maintains dependable long-term stability, reducing maintenance frequency for users.

Furthermore, the machine boasts strong structural rigidity and enhanced accuracy, making it fully capable of handling complex and demanding machining applications.