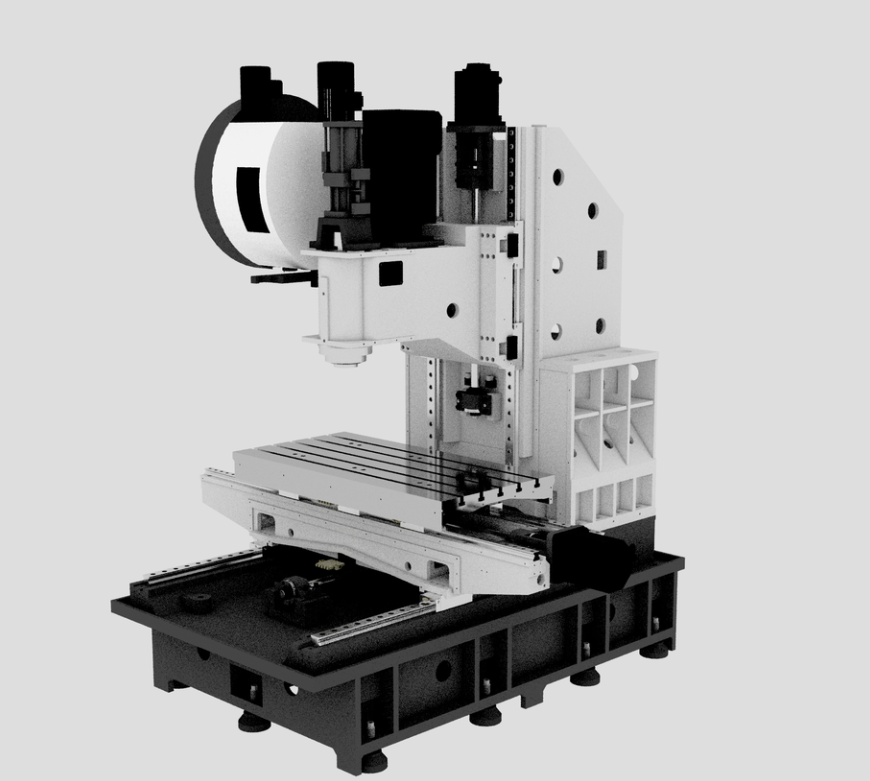

Main Features:

- The spindle assembly adopts the BT40 specification from KENTURN, operating at a rated speed of 8000rpm to meet diverse machining speed demands.

- High-precision ball screws are sourced from renowned brands—either PMI or HIWIN—ensuring stable transmission and accurate positioning.

- For tool changing, the machine is equipped with a 24-tool disk-type automatic tool changer (ATC) manufactured by OSHIMA, enabling efficient tool switching.

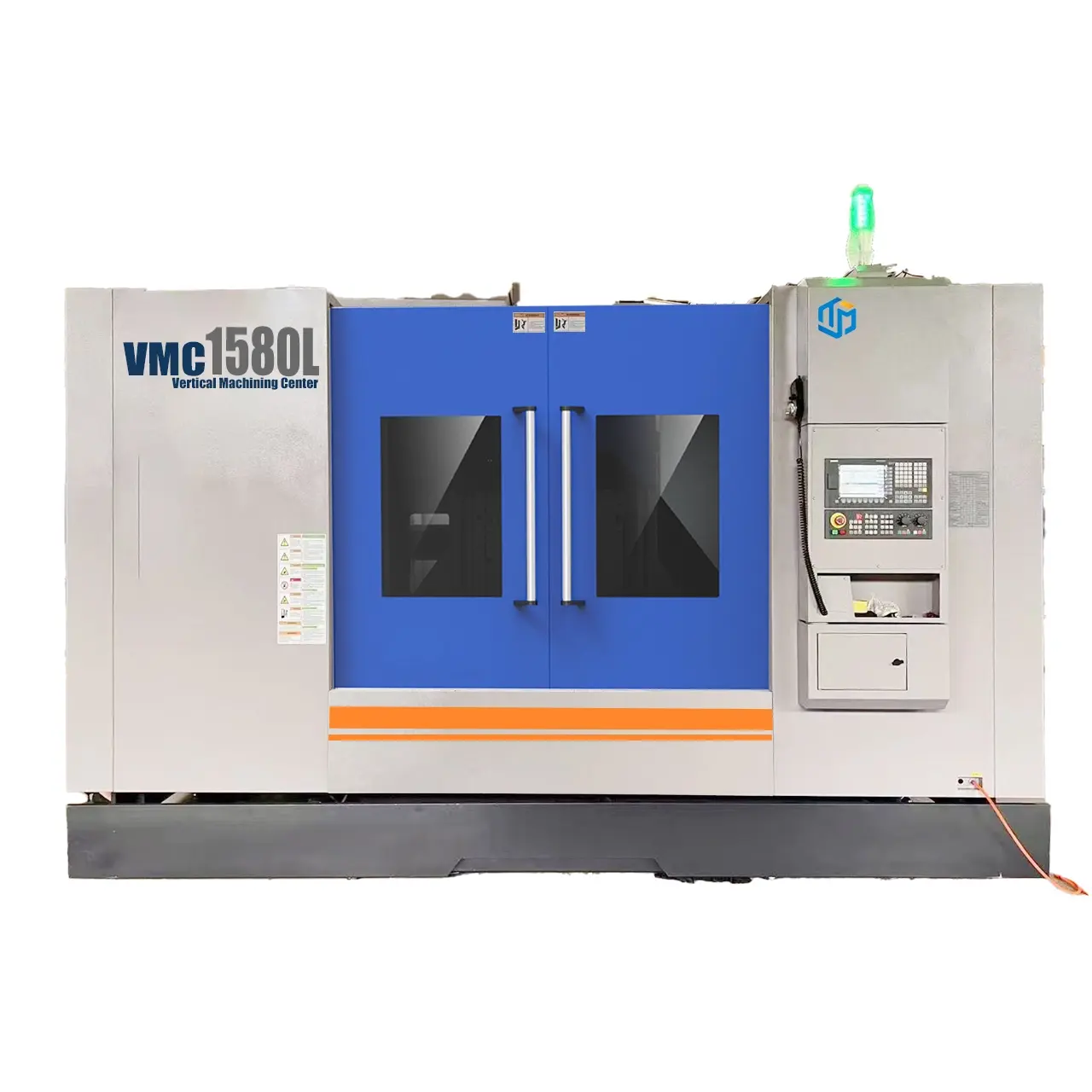

- The standard CNC control system is FANUC Oi MF(5); for customized needs, Mitsubishi or Siemens control systems are available as optional alternatives.

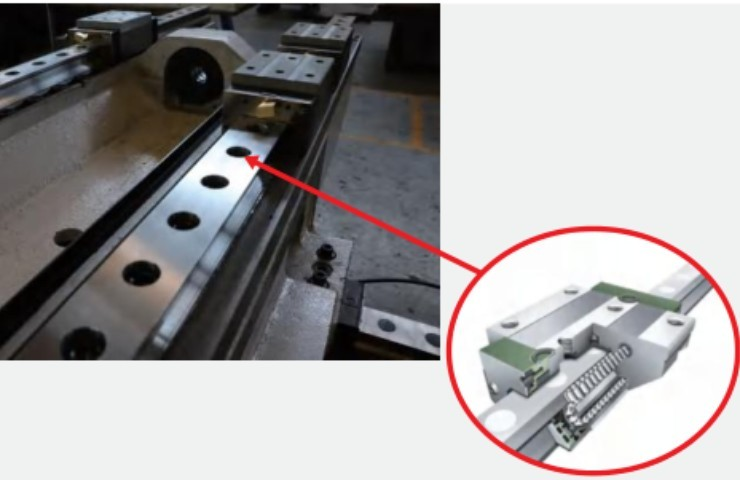

- The linear guideway structure features an optimized heavy-rail design, enhancing load-bearing capacity and movement stability during machining.

- This machine is well-suited for processing components across multiple industries, including the automotive sector and mold manufacturing.