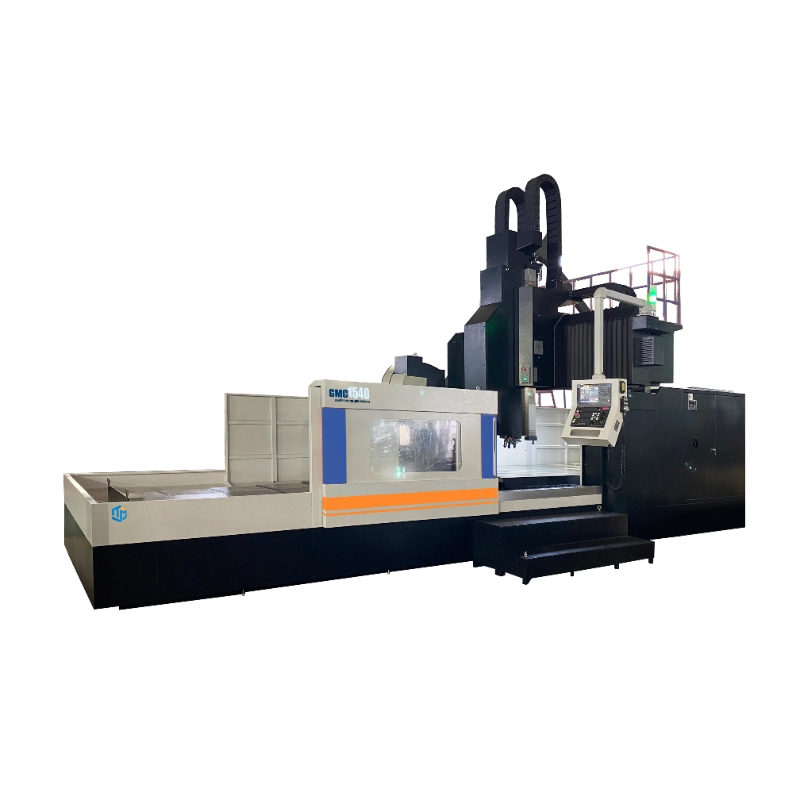

A Gantry Machining Center is a heavy-duty CNC machine tool designed for large-scale and high-precision machining. It features a gantry-structured frame for strong rigidity, enabling stable processing of large workpieces like molds, machine beds, and aerospace components.

Why Gantry-Type Machining Centers Are the Ideal Choice for Large and Heavy Workpieces

It's common knowledge that small workpieces are machined with small machines, and large workpieces with large machines. However, the reasons behind this are often unclear. Large workpieces also present their own production and processing challenges. These challenges typically include: achieving the required machining accuracy, ensuring stability during machining, maintaining precise positioning during multiple movements, overcoming surface roughness caused by vibration, and mitigating the cumulative errors resulting from repeated clamping.

Therefore, to avoid wasting time and labor costs due to using unsuitable machines, gantry-type machining centers are the appropriate choice for machining large workpieces. Why are gantry-type machining centers more suitable? Our engineers will explain from the following aspects:

What makes gantry machines so stable under heavy cutting?

Gantry-type machining centers primarily employ a symmetrical structure with double columns and a crossbeam. The advantage of this structure is that the cutting force travels through the spindle → crossbeam → column → bed, forming a complete and symmetrical force path. This results in less structural deformation and higher stability under heavy cutting conditions. The bed, column, and crossbeam of a gantry-type machining center are typically larger and thicker in cross-section, using high-strength cast iron or welded structures. If you’ve worked with heavy machinery, you know this kind of structure is stiffer and absorbs vibration better. This is why structural stability is one of the biggest advantages of gantry-type machining centers.

Fewer errors from a single clamping:

When machining complex workpieces, we may need to clamp multiple times to meet basic machining requirements. However, multiple clampings can lead to problems, as accumulated errors during machining ultimately result in wasted effort. With a gantry-type machining center, most machining operations can be completed in a single clamping. This results in better positional consistency, shorter clamping and alignment times, and higher overall machining efficiency. For workshops handling medium to large-scale batch production, this directly impacts production efficiency and cost control.

How to Choose the Right Gantry?

While many factories know they need a gantry-type machining center to assist with machining, which model best suits their needs? TopMade will use our GMC1016 and GMC2540 as examples:

For workshops machining medium-sized but heavy workpieces (such as small mold frames, mechanical parts, or thick steel plates), our GMC1016 is ideal. It is compact enough to save space, yet robust enough to handle heavy-duty cutting. Here are its key features:

- Table size: 1600 × 1000 mm (provides ample space for medium-sized parts, avoiding overcrowding)

- Spindle taper: BT50 (ideal for heavy-duty cutting, ensuring secure and stable tool clamping)

- Maximum spindle speed: 7000 rpm (balances the high torque required for roughing with the fine surface finish needed for finishing)

- Maximum table load: 3.5 tons (easily handles heavy parts that smaller machine tools struggle to handle)

If you are machining truly oversized, heavy-duty parts—such as large structural components, full-size machine tool frames, or large industrial steel plates—our GMC2540 is designed to meet the challenge. This machine tool is designed for industrial-grade machining, with extremely high requirements for size and load capacity. Its specifications fully meet these needs:

- Table size: 4000 × 2500 mm (easily accommodates even the largest workpieces, eliminating the need to spread them across multiple machine tools)

- Spindle taper: BT50 (consistent with the GMC1016, ensuring reliable heavy-duty cutting performance)

- Maximum spindle speed: 6000 rpm (optimized for high torque, enabling efficient machining of heavy, high-toughness materials)

- Maximum table load: 24 tons (capable of machining large castings and structural components without bending or deformation)

If you are evaluating whether a gantry-type machining center is suitable for your production needs, please feel free to share information about typical workpieces and machining requirements. TopMade's professional engineering team can help you assess whether models such as the GMC1016 or GMC2540 meet your application requirements, or whether there are other more suitable configurations.