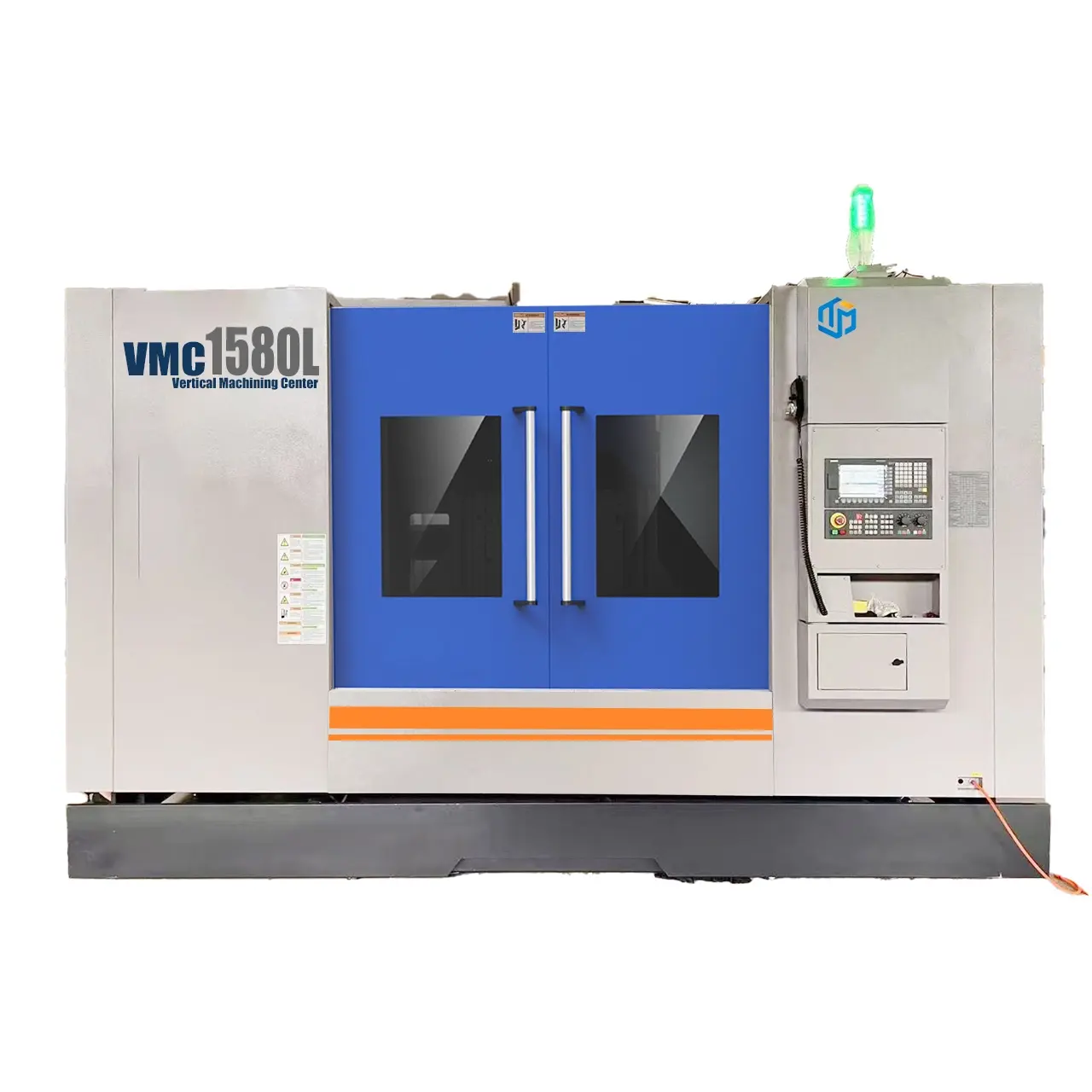

Features:

1. All structural components are engineered using advanced Finite Element Analysis. This method delivers in-depth insights into the structure’s stress and strain states, guaranteeing superior machine rigidity and long-term operational stability.

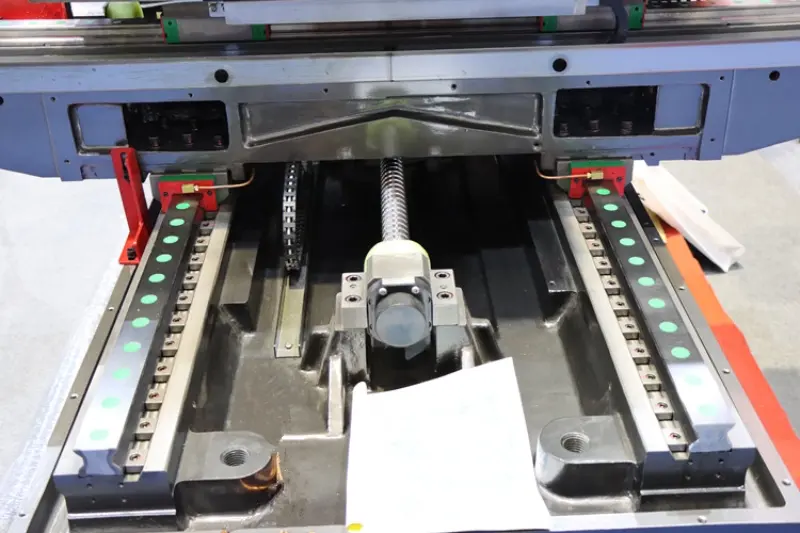

2. The X, Y, and Z axes are equipped with pre-tensioned ball screws, which enhance positioning accuracy and eliminate potential errors in location.

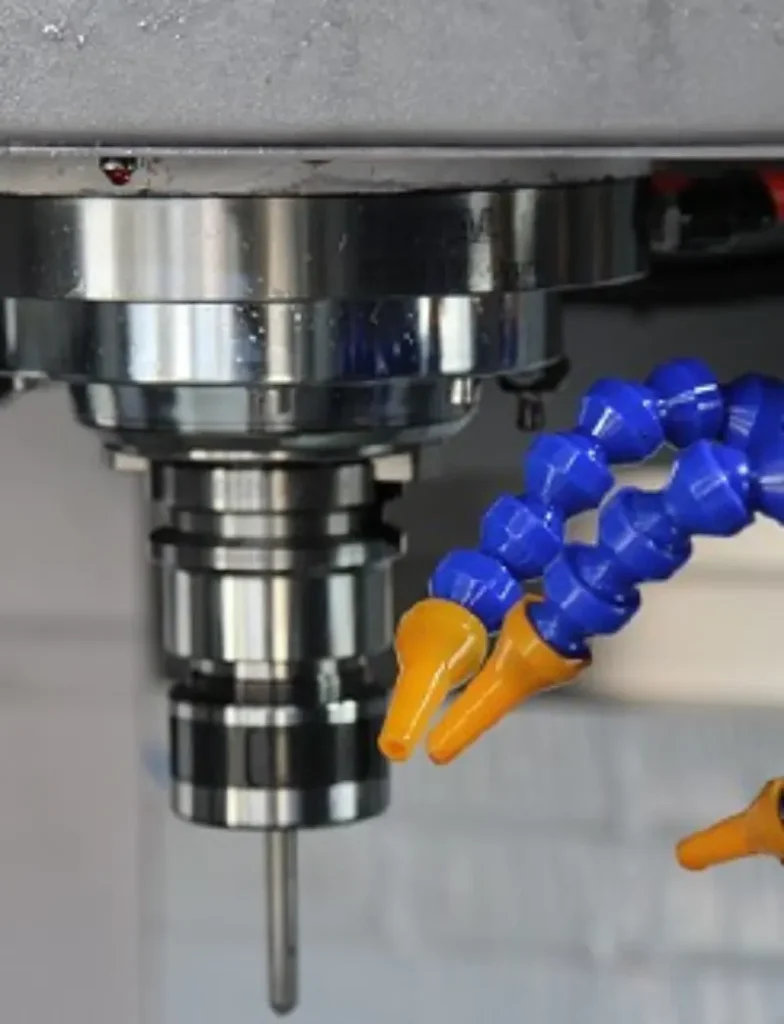

3. Critical contact surfaces—including the spindle stock end face, screw support faces, and block contact faces—undergo full hand scraping. This process boosts machining precision and ensures smoother feeding movements.

4. The machine’s framework is crafted from high-grade Meehanite cast iron, with stress relief treatment applied. This combination ensures exceptional rigidity and maintains precision over time. 5. The column and bed are designed with an oversized structure, providing the machine frame with extra-high rigidity.