Mainly used for turning inner and outer cylindrical surface, end surface, taper surface, arc surface and thead of shaft, etc., with high efficiency and accurate processing. Top Made precision cnc lathe CK6150 will offer you perfect service by excellent performance, strong rigidity, long-term stability and higher accuracy.

| Specification Capacity | CK6150 |

| Chuck size | 10″ |

| Max.swing dia over bed | 500mm |

| Max.swing dia over slide | 285mm |

| Distance between center | 750/1000/1500/2000mm |

| Width of bed | 400mm |

| Spindle | |

| Spindle speed range | 45-180/180-750/600-1600rpm |

| Spindle bore | Φ82mm |

| Max.dia of through-hole | Φ70mm |

| Spindle nose | A2-8(*105mmforA2-11) |

| SSpindle taper | Φ90mm1:20,*105mmfor105mm1:20 |

| Axis | |

| Xaxis travel | 295mm |

| Zaxis travel | 750/1000/1500/2000mm |

| XZ axis rapid traverse | 6/8m/min |

| Turret type | |

| Turret type | Electrictype |

| No of tool stations | 4,*6,*8position |

| Max.section of tool | 25x25mm |

| Tailstock | |

| External diameter | Φ80mm |

| Travel of tailstock quill | 150mm |

| Taper of talstock quill | MT5 |

| Motor | |

| Spindle motor power | 7.5kw,*11kw |

| Coolant pump power | 250w |

| Machine Dimensioris | |

| Overal dimension (L×W×H) | 2420/2860/3110/3620x1600x1750mm |

| Packing size(L×W×H) | 2600/3050/3350/3850x1800x2220mm |

| N.W | 2750/3100/3350/3550kg |

| GW | 3000/3450/3750/3950kg |

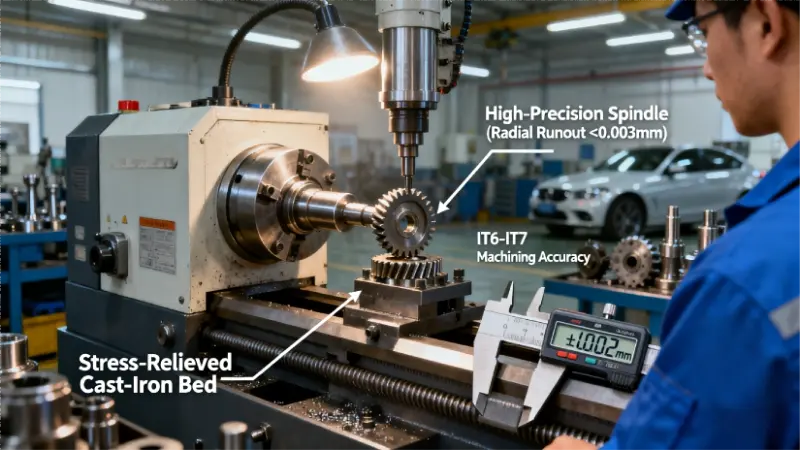

Top-Tier Precision: Gets consistent results with a stable cast-iron bed (stress-relieved for long-term accuracy) and high-precision spindle. Machines parts to IT6-IT7 level—great for tight-tolerance jobs like auto parts or precision components.

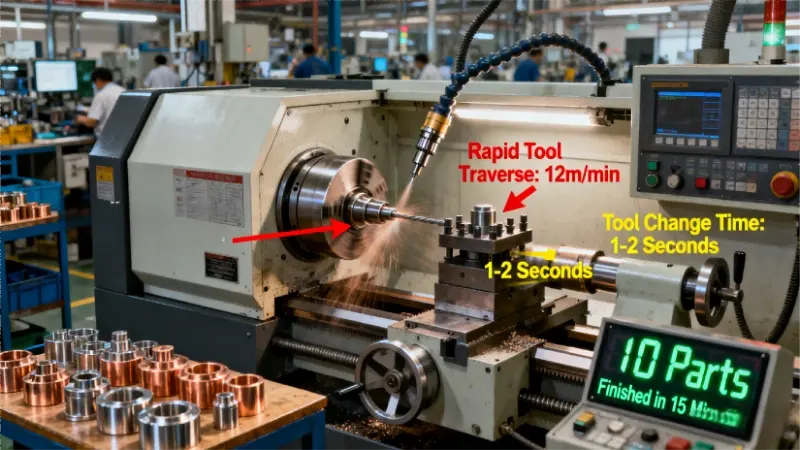

Boost Productivity: Spindle speeds up to 1600r/min handle steel, aluminum, and copper with ease. Rapid tool traverse (12m/min) cuts wait time, and the multi-station turret swaps tools in 1-2 seconds—no more slow, manual tool changes.

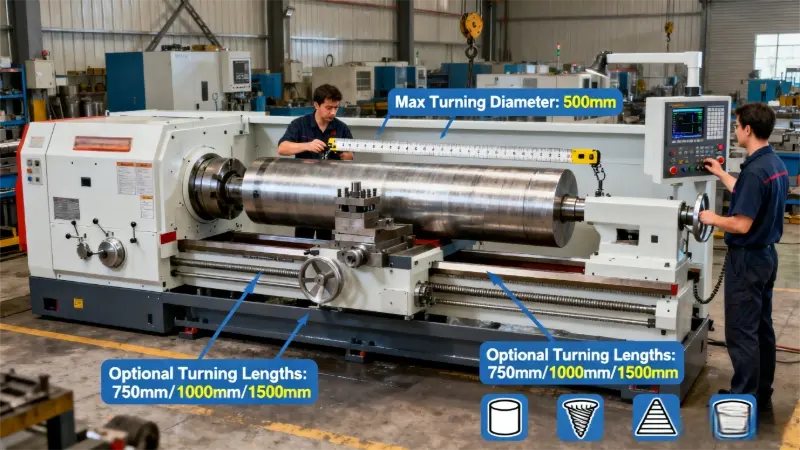

Handles Big Jobs: Max turning diameter of 500mm and optional turning lengths (750mm/1000mm/1500mm) fit large workpieces. Turns cylinders, cones, threads, grooves, and end faces—one machine for multiple tasks.

Easy to Use: 10-inch color touchscreen + simple buttons mean new operators learn fast. CNC system has auto-programming and tool compensation—no complex coding needed. Modular design also makes maintenance quick (less downtime!).

Save Energy & Money: Variable-frequency spindle motor cuts energy use by 20% vs. old lathes. Fully enclosed guard keeps chips and fluid contained—cleaner shop, safer workers.