1. In line with design concept of driven at the center of gravity, the machine equipped with double balance counter weight. Meanwhile thecenter of ram falls on the center of axis, with equalized ram guideway allocation. The design eliminates bending of ram guideway whenram moves up and down. Consequently Z axis can perfom with high stability and accuracy.

2. Equipped with oil chiller, cycle cooling source for spindle unit and motor cabine.

3. Equipped with heat exchanger, the electric cabinet can abstrcat heat eficiently during work

4. Lubrication station is controlled by CNC system which can test and alamm automatically.

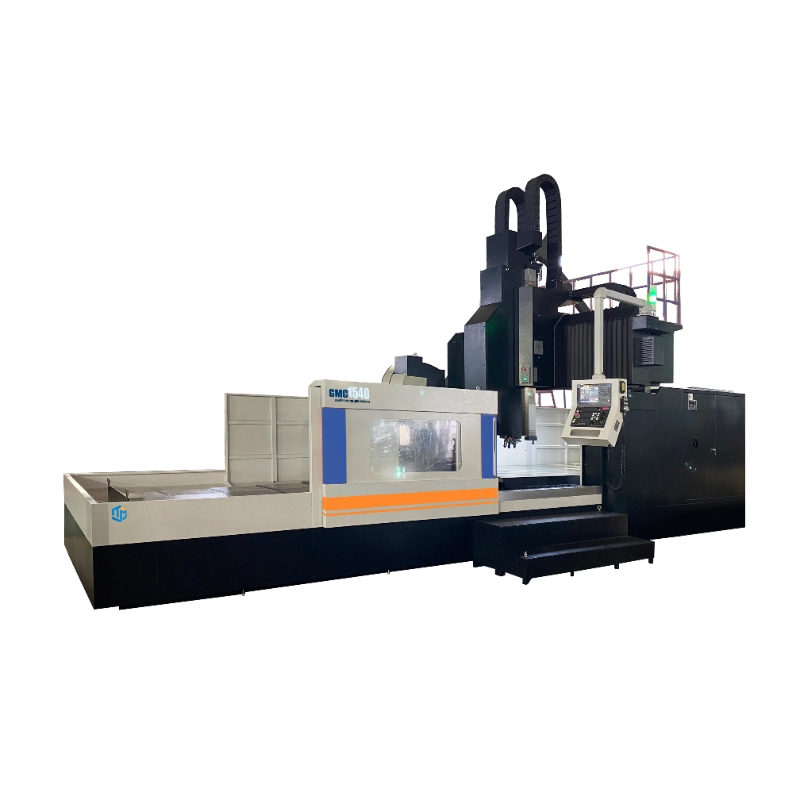

| Specification | GMC2230 |

| Worktable | |

| Worktable size (L×W) | 3000×2000mm |

| T-slots size (N×W×D) | 11-22×160mm |

| Travel | |

| X/Y/Z axis travel | 3200/2250/1000mm |

| Capacity | |

| Distance from spindle nose to worktable surface | 220-1220mm |

| Distance between two columns | 2400mm |

| Spindle | |

| Spindle taper | BT50 |

| Spindle power | 15/18.5kw |

| Max. spindle speed | 6000rpm |

| Spindle torque | 572N·m |

| Feed | |

| Rapid feed speed (X/Y/Z) | 10/10/10m/min |

| Ball screw (diameter+lead) | |

| X/Y/Z axis ball screw | 8020/6320/5016 |

| X/Y/Z guideway type | X/Y:roller linear guideways, Z:box guideway |

| Tool magazine | |

| Tool magazine capacity | 24T |

| Max. length of tool | 350mm |

| Tool change time (T-T) | 3s |

| Positioning accuracy (GB standard) | |

| Positioning accuracy(X/Y/Z) | 0.03mm |

| Re-positioning accuracy(X/Y/Z) | 0.018mm |

| Machine dimension | |

| L×W×H | 8800×6400×5500mm |

| Machine weight | |

| Max. loading of worktable | 12t |

| N.W | 33.5t |

Large Processing Range, Easily Handles Large Workpieces

Due to its unique gantry structure, the gantry machining center boasts an exceptional span, easily accommodating and processing a wide range of large and heavy workpieces. Whether it’s large components in the aerospace industry, massive parts in shipbuilding, or giant molds in the mold and die industry, it can easily handle these tasks, providing a reliable solution for the integrated processing of large workpieces.

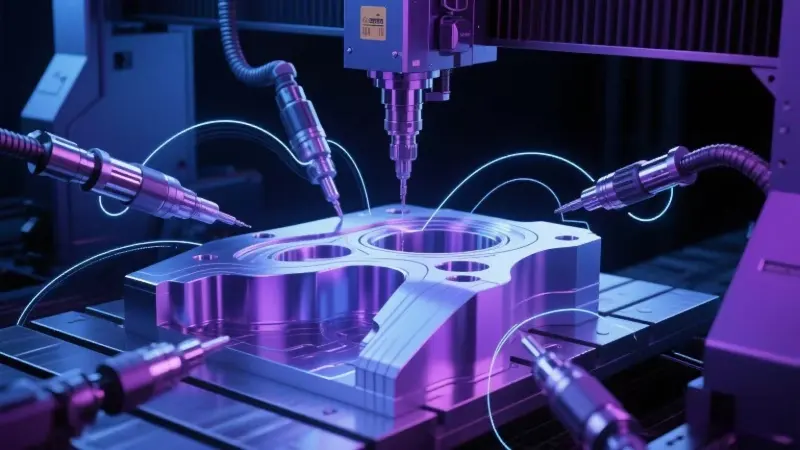

High Rigidity and Stability, Ensuring Precision

The gantry frame provides solid support for the machining center. This stable structure effectively reduces vibration during high-speed or heavy cutting, ensuring precise machining. Gantry machining centers can meet all requirements for dimensional accuracy, flatness, and positional tolerances, making them particularly suitable for machining precision parts, such as large molds and aerospace components, which require extremely high precision.

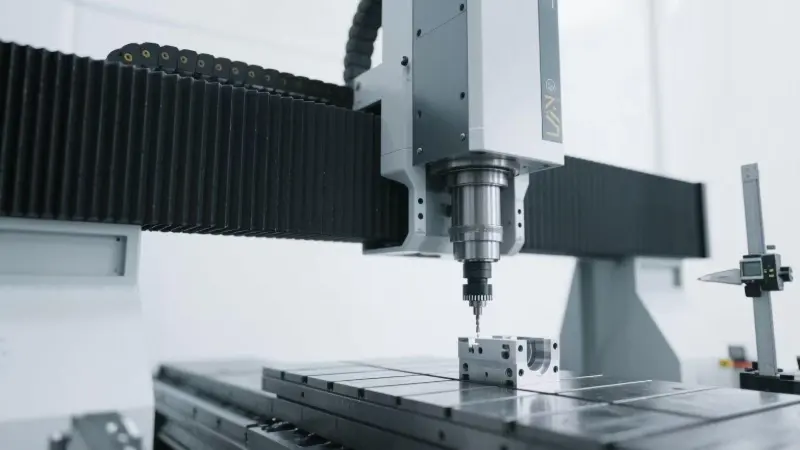

Multi-Axis Linkage Enables Complex Contour Machining

Typically equipped with a 3- to 5-axis linkage system, gantry machining centers can complete complex contour machining, such as curved and inclined surfaces, in a single clamping. This multi-axis linkage capability reduces workpiece re-clamping, minimizes clamping errors, and improves machining consistency, providing a strong guarantee for the efficient machining of complex parts.

Efficient Machining and Improved Production Efficiency

Equipped with a high-power spindle and rapid feed system, gantry machining centers are suitable for heavy cutting and high-volume production. They can quickly remove material, shorten machining time, and significantly improve machining efficiency, providing powerful support for large-scale production.