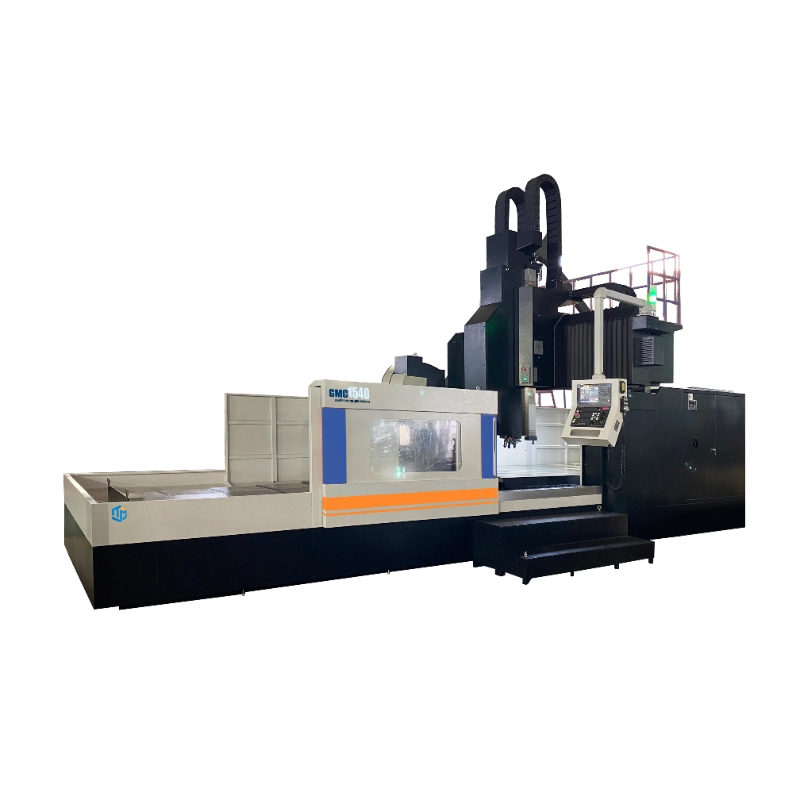

This machine is suitable for miling, boring, dhlling, threading, etc. Machining ferrous and non ferrous metals, it can finished variousprocess with only once install the work piece, ensure the quality of products and production effciency.

| Specification | GMC1016 |

| Worktable | |

| Worktable size (L×W) | 1600×1000mm |

| T-slots size (N×W×D) | 7-22x125mm |

| Travel | |

| X/Y/Z axis travel | 1650/1100/600mm |

| Capacity | |

| Distance from spindle nose to worktable surface | 160-760mm |

| Distance between two columns | 1250mm |

| Spindle | |

| Spindle taper | BT50 |

| Spindle power | 15/18.5kw |

| Max. spindle speed | 7000rpm |

| Spindle torque | 143N·m |

| Feed | |

| Rapid feed speed (X/Y/Z) | 20/20/12m/min |

| Ball screw (diameter+lead) | |

| X/Y/Z axis ball screw | 6320/5012/5020 |

| X/Y/Z guideway type | X/Y:roller linear guideways, Z:box guideway |

| Tool magazine | |

| Tool magazine capacity | 24T |

| Max. length of tool | 350mm |

| Tool change time (T-T) | 3s |

| Positioning accuracy (GB standard) | |

| Positioning accuracy(X/Y/Z) | 0.03mm |

| Re-positioning accuracy(X/Y/Z) | 0.018mm |

| Machine dimension | |

| L×W×H | 6000×4000×3900mm |

| Machine weight | |

| Max. loading of worktable | 3.5t |

| N.W | 18t |

The GMC1016 CNC gantry machining center features powerful performance parameters, which lay a solid foundation for its efficient machining. Its spacious worktable can meet the machining needs of large workpieces, while its strong load-bearing capacity enables stable support for heavy workpieces during machining.

In terms of machining accuracy, the GMC1016 excels. It adopts high-precision guide rails and lead screws, and when combined with an advanced CNC system, achieves micron-level machining accuracy—ensuring that machined workpieces boast precise dimensions and a high surface finish.

High machining efficiency is another key advantage of the GMC1016. Its high-speed spindle and rapid feed rates can significantly reduce machining time, boost production efficiency, and thus bring greater economic benefits to companies.

The GMC1016 also excels in operational convenience and intelligent functionality. Its user interface is simple and intuitive, while its CNC system is powerful—enabling automated processing, reducing manual intervention, lowering operational difficulty, and enhancing production stability and reliability.