1. De acuerdo con el concepto de diseño de accionamiento por centro de gravedad, la máquina está equipada con un contrapeso de doble equilibrio. El centro del pistón se encuentra en el centro del eje, con una distribución uniforme de las guías del pistón. Este diseño elimina la flexión de las guías del pistón al subir y bajar. Como resultado, el eje Z ofrece alta estabilidad y precisión.

2. Equipado con enfriador de aceite, fuente de enfriamiento de ciclo para unidad de husillo y cabina de motor.

3. Equipado con intercambiador de calor, el gabinete eléctrico puede absorber calor de manera eficiente durante el trabajo.

4. La estación de lubricación está controlada por un sistema CNC que puede probar y lubricar automáticamente.

| Especificación | GMC2230 |

| Mesa de trabajo | |

| Tamaño de la mesa de trabajo (L×An) | 3000×2000 mm |

| Tamaño de las ranuras en T (N×W×D) | 11-22×160 mm |

| Viajar | |

| Recorrido del eje X/Y/Z | 3200/2250/1000 mm |

| Capacidad | |

| Distancia desde la punta del husillo hasta la superficie de la mesa de trabajo | 220-1220 mm |

| Distancia entre dos columnas | 2400 mm |

| Huso | |

| Cono del husillo | BT50 |

| Potencia del husillo | 15/18,5 kW |

| Velocidad máxima del husillo | 6000 rpm |

| Par de torsión del husillo | 572 N·m |

| Alimentar | |

| Velocidad de alimentación rápida (X/Y/Z) | 10/10/10 m/min |

| Tornillo de bola (diámetro + paso) | |

| Tornillo de bola del eje X/Y/Z | 8020/6320/5016 |

| Tipo de guía X/Y/Z | Guías lineales de rodillos X/Y, guías de caja Z |

| Almacén de herramientas | |

| Capacidad del almacén de herramientas | 24T |

| Longitud máxima de la herramienta | 350 mm |

| Tiempo de cambio de herramienta (TT) | 3 segundos |

| Precisión de posicionamiento (estándar GB) | |

| Precisión de posicionamiento (X/Y/Z) | 0,03 mm |

| Precisión de reposicionamiento (X/Y/Z) | 0,018 mm |

| Dimensión de la máquina | |

| Largo × Ancho × Alto | 8800×6400×5500 mm |

| Peso de la máquina | |

| Carga máxima de la mesa de trabajo | 12 toneladas |

| noroeste | 33,5 toneladas |

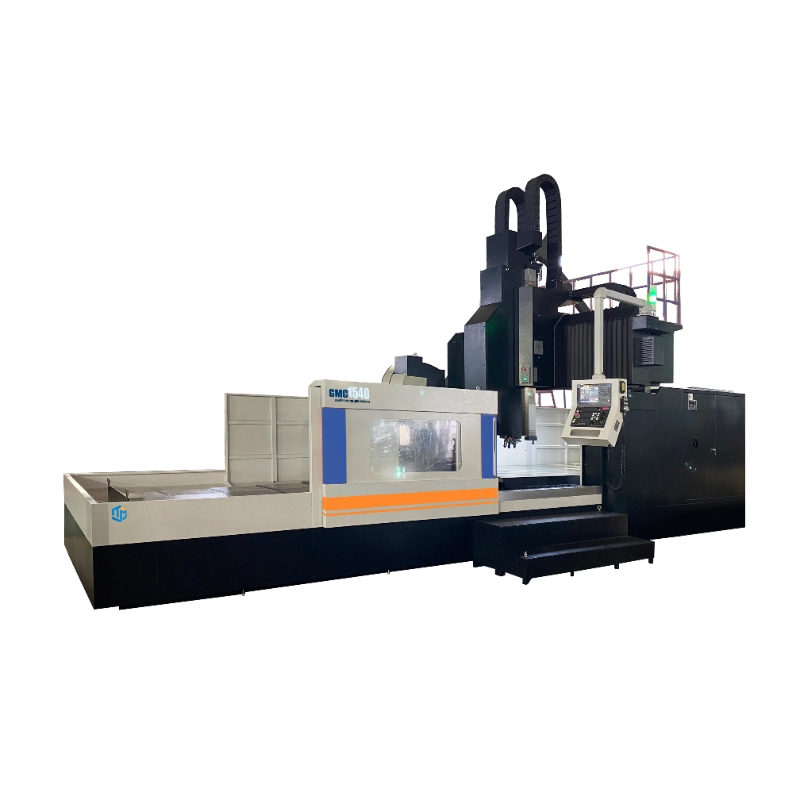

Amplio rango de procesamiento, maneja fácilmente piezas de trabajo grandes

Gracias a su exclusiva estructura de pórtico, el centro de mecanizado de pórtico ofrece una envergadura excepcional, lo que le permite alojar y procesar fácilmente una amplia gama de piezas grandes y pesadas. Ya se trate de componentes de gran tamaño en la industria aeroespacial, piezas masivas en la construcción naval o moldes gigantes en la industria de moldes y matrices, puede realizar estas tareas con facilidad, ofreciendo una solución fiable para el procesamiento integrado de piezas de gran tamaño.

Alta rigidez y estabilidad, garantizando precisión

El bastidor de pórtico proporciona un soporte sólido al centro de mecanizado. Esta estructura estable reduce eficazmente la vibración durante cortes pesados o de alta velocidad, garantizando un mecanizado preciso. Los centros de mecanizado de pórtico cumplen con todos los requisitos de precisión dimensional, planitud y tolerancias de posición, lo que los hace especialmente adecuados para el mecanizado de piezas de precisión, como moldes de gran tamaño y componentes aeroespaciales, que requieren una precisión extremadamente alta.

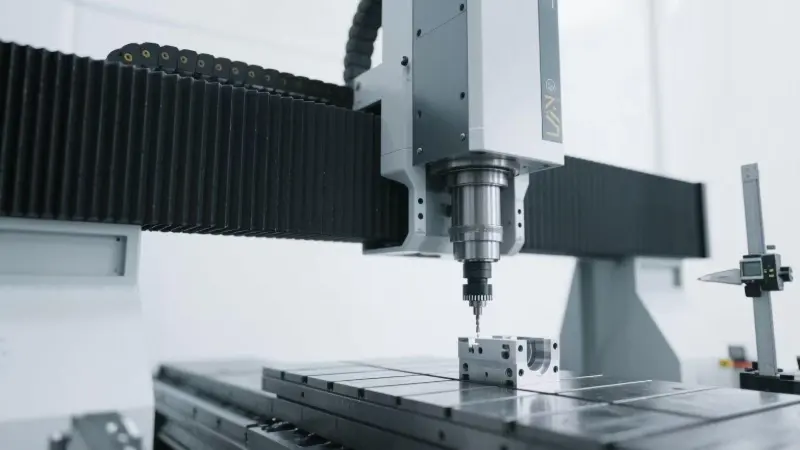

El enlace multieje permite el mecanizado de contornos complejos

Los centros de mecanizado de pórtico, generalmente equipados con un sistema de varillaje de 3 a 5 ejes, pueden completar el mecanizado de contornos complejos, como superficies curvas e inclinadas, con una sola sujeción. Esta capacidad de varillaje multieje reduce la necesidad de reabrochar la pieza, minimiza los errores de sujeción y mejora la consistencia del mecanizado, lo que garantiza un mecanizado eficiente de piezas complejas.

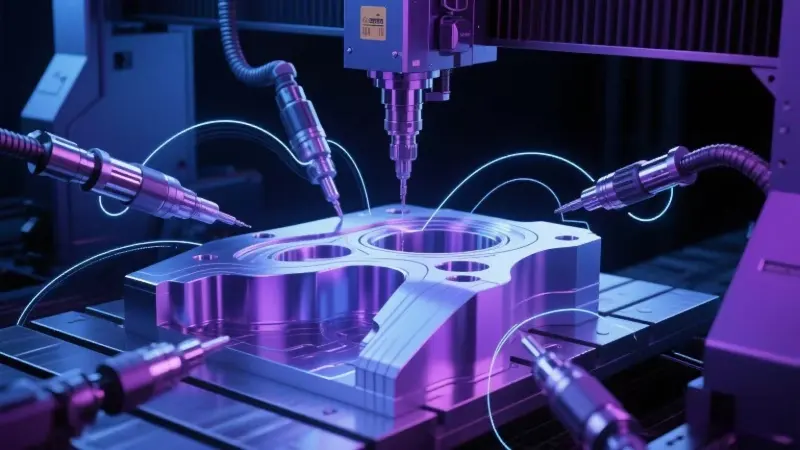

Mecanizado eficiente y mayor eficiencia de producción

Equipados con un husillo de alta potencia y un sistema de avance rápido, los centros de mecanizado de pórtico son ideales para cortes pesados y producción de gran volumen. Permiten retirar material rápidamente, acortar el tiempo de mecanizado y mejorar significativamente la eficiencia, ofreciendo un potente soporte para la producción a gran escala.