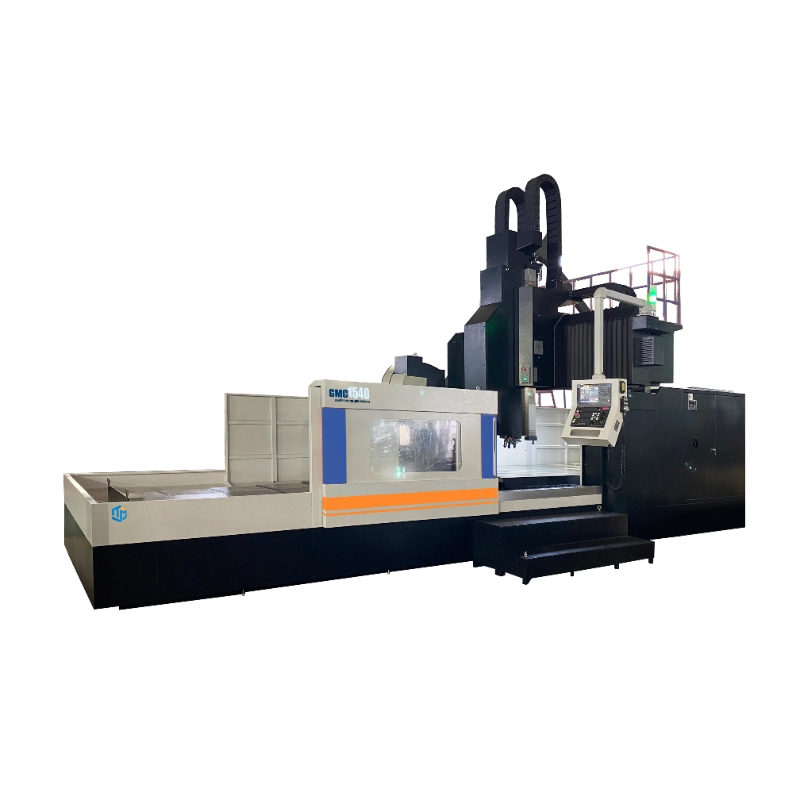

Esta máquina es adecuada para fresado, taladrado, desbarbado, roscado, etc. Mecanizado de metales ferrosos y no ferrosos, puede terminar varios procesos con solo instalar la pieza de trabajo, lo que garantiza la calidad de los productos y la eficiencia de la producción.

| Especificación | GMC1016 |

| Mesa de trabajo | |

| Tamaño de la mesa de trabajo (L×An) | 1600×1000 mm |

| Tamaño de las ranuras en T (N×W×D) | 7-22x125 mm |

| Viajar | |

| Recorrido del eje X/Y/Z | 1650/1100/600 mm |

| Capacidad | |

| Distancia desde la punta del husillo hasta la superficie de la mesa de trabajo | 160-760 mm |

| Distancia entre dos columnas | 1250 mm |

| Huso | |

| Cono del husillo | BT50 |

| Potencia del husillo | 15/18,5 kW |

| Velocidad máxima del husillo | 7000 rpm |

| Par de torsión del husillo | 143 N·m |

| Alimentar | |

| Velocidad de alimentación rápida (X/Y/Z) | 20/20/12 m/min |

| Tornillo de bola (diámetro + paso) | |

| Tornillo de bola del eje X/Y/Z | 6320/5012/5020 |

| Tipo de guía X/Y/Z | Guías lineales de rodillos X/Y, guías de caja Z |

| Almacén de herramientas | |

| Capacidad del almacén de herramientas | 24T |

| Longitud máxima de la herramienta | 350 mm |

| Tiempo de cambio de herramienta (TT) | 3 segundos |

| Precisión de posicionamiento (estándar GB) | |

| Precisión de posicionamiento (X/Y/Z) | 0,03 mm |

| Precisión de reposicionamiento (X/Y/Z) | 0,018 mm |

| Dimensión de la máquina | |

| Largo × Ancho × Alto | 6000×4000×3900 mm |

| Peso de la máquina | |

| Carga máxima de la mesa de trabajo | 3,5 toneladas |

| noroeste | 18t |

El centro de mecanizado de pórtico CNC GMC1016 ofrece un rendimiento excepcional, lo que sienta las bases para un mecanizado eficiente. Su amplia mesa de trabajo satisface las necesidades de mecanizado de piezas de gran tamaño, mientras que su gran capacidad de carga permite un soporte estable para piezas pesadas durante el mecanizado.

En cuanto a precisión de mecanizado, la GMC1016 destaca. Incorpora rieles guía y husillos de alta precisión, y al combinarse con un avanzado sistema CNC, alcanza una precisión micrométrica, garantizando así piezas mecanizadas con dimensiones precisas y un excelente acabado superficial.

La alta eficiencia de mecanizado es otra ventaja clave del GMC1016. Su husillo de alta velocidad y sus rápidos avances pueden reducir significativamente el tiempo de mecanizado, aumentar la eficiencia de la producción y, por lo tanto, generar mayores beneficios económicos para las empresas.

La GMC1016 también destaca por su comodidad operativa y funcionalidad inteligente. Su interfaz de usuario es sencilla e intuitiva, mientras que su potente sistema CNC permite el procesamiento automatizado, reduce la intervención manual, reduce la dificultad operativa y mejora la estabilidad y la fiabilidad de la producción.