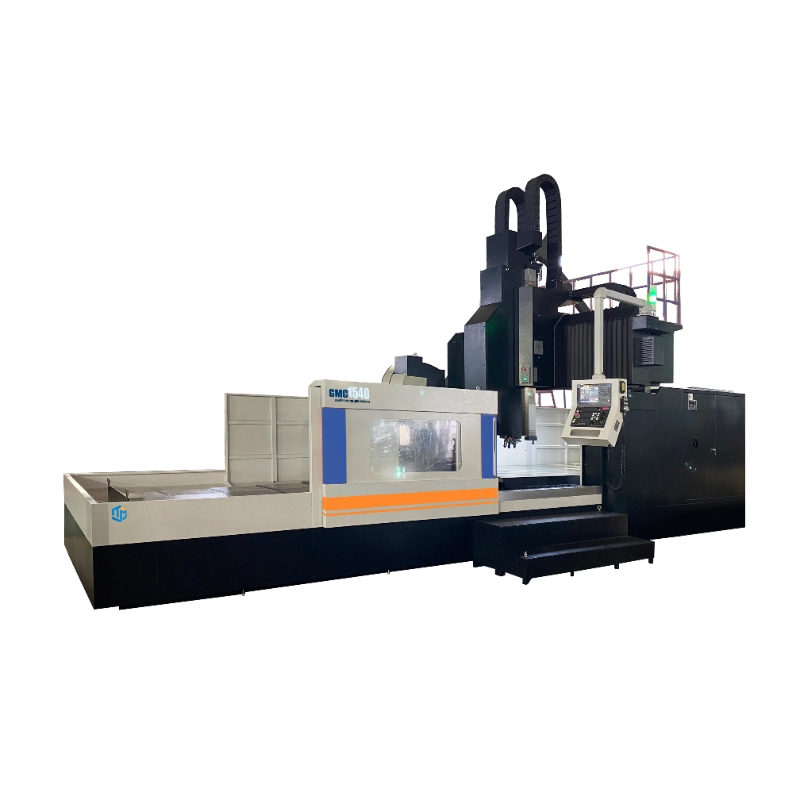

Esta máquina es adecuada para fresar, taladrar, perforar, roscar, etc. Mecanizar metales ferrosos y no ferrosos, puede terminar varios procesos con solo instalar la pieza de trabajo, lo que garantiza la calidad de los productos y la eficiencia de la producción.

| Especificación | GMC1540 |

| Mesa de trabajo | |

| Tamaño de la mesa de trabajo (L×An) | 4000×1500 mm |

| Tamaño de las ranuras en T (N×W×D) | 9-22×160 mm |

| Viajar | |

| Recorrido del eje X/Y/Z | 4100/1650/800 mm |

| Capacidad | |

| Distancia desde la punta del husillo hasta la superficie de la mesa de trabajo | 160-960 mm |

| Distancia entre dos columnas | 1650 mm |

| Huso | |

| Cono del husillo | BT50 |

| Potencia del husillo | 15/18,5 kW |

| Velocidad máxima del husillo | 6000 rpm |

| Par de torsión del husillo | 143 N·m |

| Alimentar | |

| Velocidad de alimentación rápida (X/Y/Z) | 10/10/10 m/min |

| Tornillo de bola (diámetro + paso) | |

| Tornillo de bola del eje X/Y/Z | 8020/5016/5016 |

| Tipo de guía X/Y/Z | Guías lineales de rodillos X/Y, guías de caja Z |

| Almacén de herramientas | |

| Capacidad del almacén de herramientas | 24T |

| Longitud máxima de la herramienta | 350 mm |

| Tiempo de cambio de herramienta (TT) | 3 segundos |

| Precisión de posicionamiento (estándar GB) | |

| Precisión de posicionamiento (X/Y/Z) | 0,03 mm |

| Precisión de reposicionamiento (X/Y/Z) | 0,018 mm |

| Dimensión de la máquina | |

| Largo × Ancho × Alto | 10800×5800×5000 mm |

| Peso de la máquina | |

| Carga máxima de la mesa de trabajo | 8t |

| noroeste | 28 toneladas |

Mayor capacidad de mecanizado: Con una mesa de trabajo de gran tamaño (1500 × 4000 mm) y un recorrido vertical en el eje Z de 800 mm, la GMC1540 maneja componentes extragrandes con facilidad. La estructura de pórtico reforzada de doble columna, fabricada en hierro fundido de alta resistencia, garantiza una deflexión mínima bajo cargas pesadas, manteniendo la estabilidad durante el corte a alta velocidad.

Alto rendimiento: Equipado con un motor de husillo de 22 kW (opcional de 30 kW) y velocidades de hasta 6000 rpm, mecaniza eficientemente materiales resistentes como acero aleado y titanio. El sistema de alimentación servoaccionado alcanza velocidades de desplazamiento rápidas (X/Y/Z: 20/20/15 m/min), lo que reduce el tiempo sin corte y aumenta la productividad en 251 TP3T para la producción en lotes.

Control de Precisión Avanzado: Con un sistema CNC Heidenhain/FANUC con interpolación de 5 ejes, la máquina ofrece una precisión de posicionamiento de ±0,005 mm y una repetibilidad de ±0,003 mm. El ajustador de herramientas láser integrado y la sonda de pieza permiten la calibración automatizada, eliminando errores manuales y garantizando una calidad constante de las piezas.

Integración en Fábrica Inteligente: La HMI con pantalla táctil industrial de 19 pulgadas facilita la transferencia fluida de datos CAD/CAM y el diagnóstico remoto mediante el protocolo OPC UA. La extracción automática de virutas, el reciclaje de refrigerante y el modo de ahorro de energía (consumo en espera ≤5 kW) optimizan la eficiencia del taller y reducen los costes operativos.

Aplicaciones:

Perfecto para mecanizar piezas estructurales de gran formato, componentes de turbinas, secciones de construcción naval y matrices de precisión. Su versatilidad lo convierte en una herramienta clave para fabricantes que requieren tamaño y precisión en producciones de gran volumen.