1. Alta relación costo-rendimiento.

2. Disminución del consumo de energía en 20%, alta estabilidad.

3. Fácil de operar, programar y mantener.

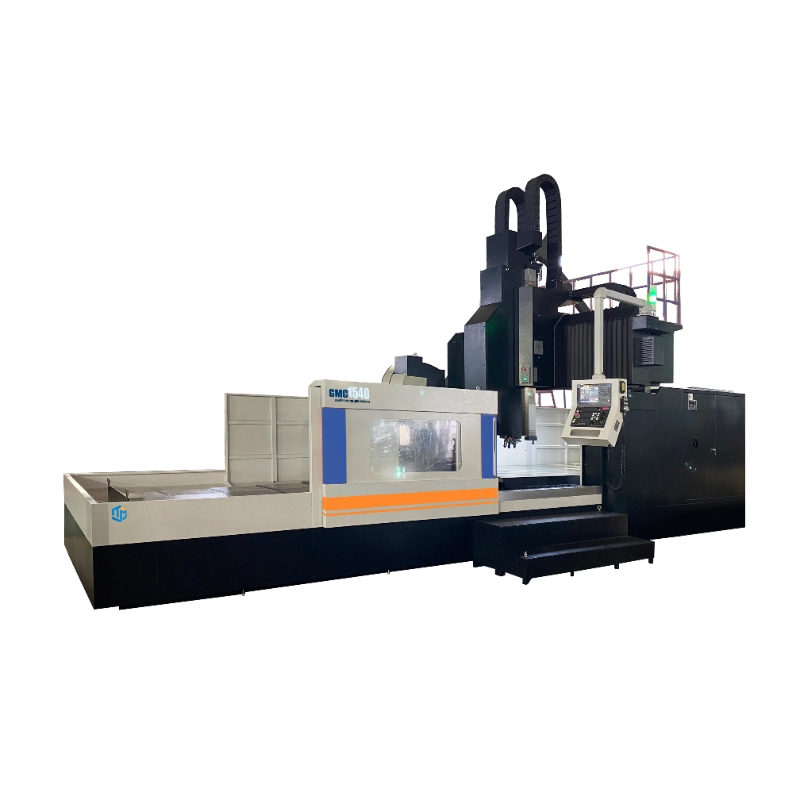

| Especificación | GMC1325 |

| Mesa de trabajo | |

| Tamaño de la mesa de trabajo (L×An) | 2500×1300 mm |

| Tamaño de las ranuras en T (N×W×D) | 7-22×160 mm |

| Viajar | |

| Recorrido del eje X/Y/Z | 2600/1400/800 mm |

| Capacidad | |

| Distancia desde la punta del husillo hasta la superficie de la mesa de trabajo | 160-960 mm |

| Distancia entre dos columnas | 1400 mm |

| Huso | |

| Cono del husillo | BT50 |

| Potencia del husillo | 15/18,5 kW |

| Velocidad máxima del husillo | 6000 rpm |

| Par de torsión del husillo | 143 N·m |

| Alimentar | |

| Velocidad de alimentación rápida (X/Y/Z) | 10/10/10 m/min |

| Tornillo de bola (diámetro + paso) | |

| Tornillo de bola del eje X/Y/Z | 6316/5016/5016 |

| Tipo de guía X/Y/Z | Guías lineales de rodillos X/Y, guías de caja Z |

| Almacén de herramientas | |

| Capacidad del almacén de herramientas | 24T |

| Longitud máxima de la herramienta | 350 mm |

| Tiempo de cambio de herramienta (TT) | 3 segundos |

| Precisión de posicionamiento (estándar GB) | |

| Precisión de posicionamiento (X/Y/Z) | 0,03 mm |

| Precisión de reposicionamiento (X/Y/Z) | 0,018 mm |

| Dimensión de la máquina | |

| Largo × Ancho × Alto | 7800×5500×5000 mm |

| Peso de la máquina | |

| Carga máxima de la mesa de trabajo | 6t |

| noroeste | 22,5 toneladas |

Precisión de mecanizado superior: Equipado con guías lineales y husillos de bolas de alta precisión, junto con un sistema CNC FANUC/Siemens de última generación, logra una precisión de posicionamiento micrométrica (±0,003 mm) y repetibilidad (±0,002 mm). El diseño de pórtico rígido minimiza la vibración, garantizando acabados superficiales impecables (Ra ≤ 1,6 μm) incluso en contornos 3D complejos.

Productividad de alta velocidad: Un potente husillo de 15 kW con velocidades de hasta 8000 rpm permite una rápida extracción de material, mientras que la alta velocidad de avance (ejes X/Y/Z: 24/24/18 m/min) reduce los tiempos de ciclo hasta en 30% en comparación con las máquinas convencionales. La amplia mesa de trabajo (1300×2500 mm) admite piezas de gran tamaño y permite una sujeción única para el procesamiento multioperación.

Inteligente y fácil de usar: La HMI con pantalla táctil de 15 pulgadas ofrece una programación intuitiva con compatibilidad integrada con software CAD/CAM. Funciones automatizadas como la medición de la longitud de la herramienta, la refrigeración del husillo y el transportador de virutas mejoran la seguridad operativa y reducen la intervención manual. La monitorización remota mediante conectividad IoT permite el seguimiento de la producción en tiempo real y el mantenimiento predictivo.

Duradero y de bajo mantenimiento: Fabricado con hierro fundido de alta calidad y componentes con alivio de tensión, la máquina garantiza una estabilidad a largo plazo (MTBF ≥ 5000 horas). Las guías selladas y el sistema de lubricación centralizada prolongan la vida útil, reduciendo los costos de mantenimiento en 251 TP3T al año.

Aplicaciones:

Ideal para mecanizar grandes estructuras de acero, aleaciones de aluminio, materiales compuestos y moldes de precisión. Fabricantes líderes confían en él por su fiabilidad y capacidad para cumplir con tolerancias estrictas en producciones de alto volumen.