1. High perfomance cost ratio.

2.Energy consumption decrease by 20%, high stability.

3. Easy to operate, programme and maintenance.

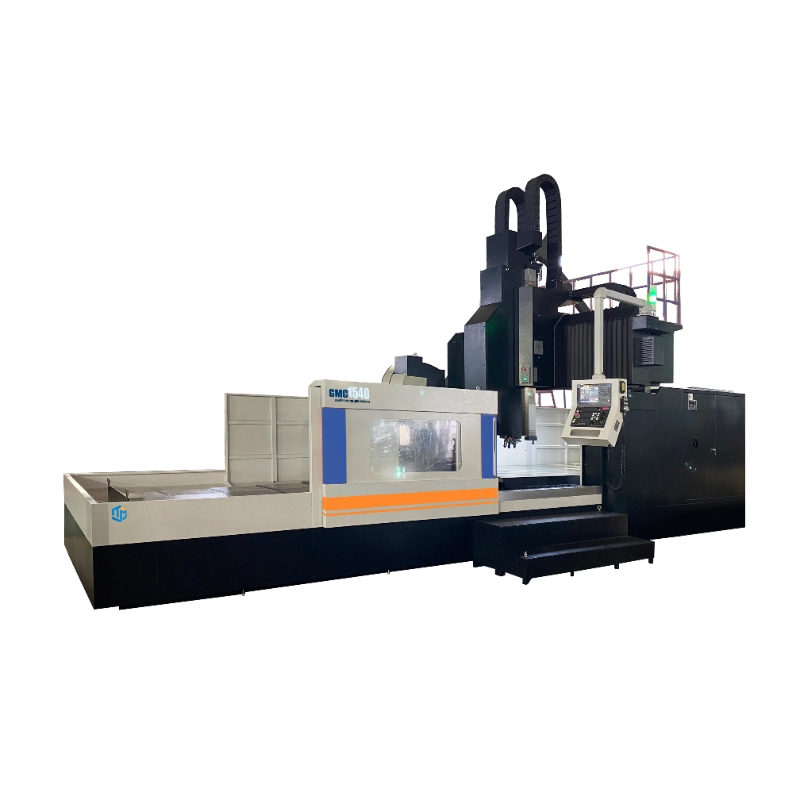

| Specification | GMC1840 |

| Worktable | |

| Worktable size (L×W) | 4000×1800mm |

| T-slots size (N×W×D) | 11-22×160mm |

| Travel | |

| X/Y/Z axis travel | 4200/1850/1000mm |

| Capacity | |

| Distance from spindle nose to worktable surface | 260-1260mm |

| Distance between two columns | 2000mm |

| Spindle | |

| Spindle taper | BT50 |

| Spindle power | 15/18.5kw |

| Max. spindle speed | 6000rpm |

| Spindle torque | 143N·m |

| Feed | |

| Rapid feed speed (X/Y/Z) | 10/10/10m/min |

| Ball screw (diameter+lead) | |

| X/Y/Z axis ball screw | 8020/6320/5016 |

| X/Y/Z guideway type | X/Y:roller linear guideways, Z:box guideway |

| Tool magazine | |

| Tool magazine capacity | 24T |

| Max. length of tool | 350mm |

| Tool change time (T-T) | 3s |

| Positioning accuracy (GB standard) | |

| Positioning accuracy(X/Y/Z) | 0.03mm |

| Re-positioning accuracy(X/Y/Z) | 0.018mm |

| Machine dimension | |

| L×W×H | 10800×6000×5500mm |

| Machine weight | |

| Max. loading of worktable | 15t |

| N.W | 35.5t |

Precision Redefined: Equipped with high-precision linear guides, ball screws, and a state-of-the-art FANUC CNC system, it delivers micron-level accuracy (±0.002mm) and exceptional surface finish, ensuring every detail meets strict tolerances.

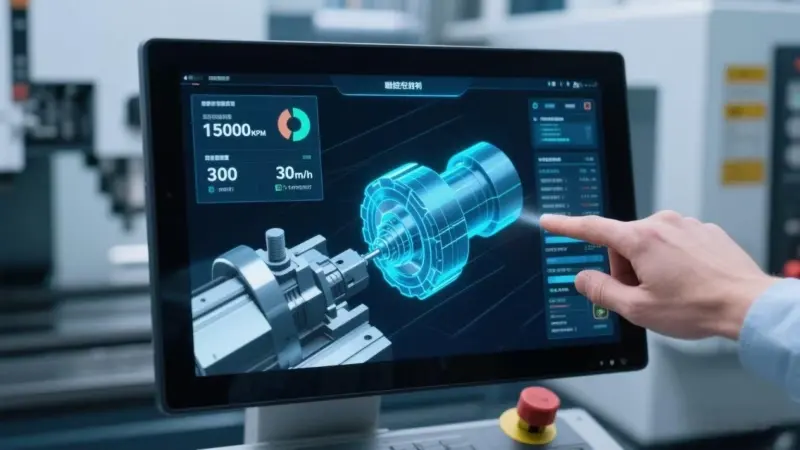

Power Meets Efficiency: Its high-torque spindle (up to 15,000 RPM) and rapid feed rates (30m/min) slash cycle times, boosting productivity while reducing energy consumption—ideal for high-volume production lines.

Smart & User-Centric: The intuitive touchscreen interface simplifies operation, while automated tool changers and programmable workflows minimize manual intervention. Remote monitoring capabilities keep you in control, even off-site.

From aerospace to heavy machinery, the GMC1840 isn’t just a machine—it’s a catalyst for manufacturing excellence.

Ready to elevate your production? Contact us for a custom quote.