The W12 series 4-roller plate rolling machines from TOP MADE are designed for high precision, efficiency, and reliability in metal forming. With a hydraulic drive system and advanced 4-roller structure, the W12 series allows for accurate positioning and one-pass plate rolling, reducing material handling and improving productivity. These machines are capable of processing various materials, including carbon steel, stainless steel, and alloy plates, and can easily form cylindrical, arc-shaped, and conical workpieces. Widely used in industries such as boilers, pressure vessels, shipbuilding, wind energy, aerospace, and steel construction, the W12 series delivers stable performance, user-friendly operation, and long service life-making it an ideal solution for both medium and heavy-duty plate rolling applications.

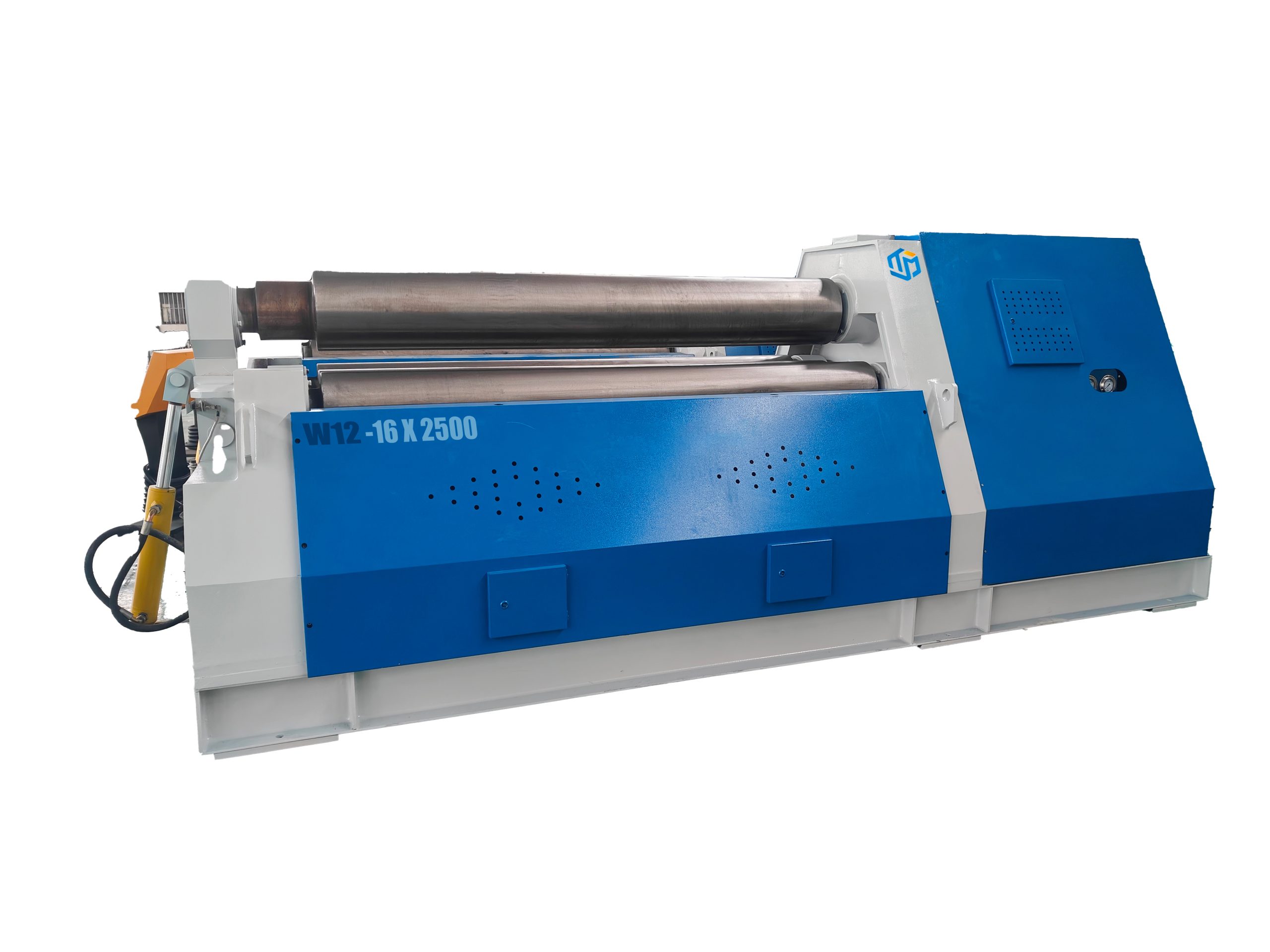

| Model | W12-12×2500 |

| Max.rolingthickness | 12mm |

| Max. pre-bendingthickness | 8mm |

| Max.rollingwidth | 2500mm |

| Diameter oftop roler | 280mm |

| Diameterof bottom roller | 260mm |

| Diameter of side rolers | 220mm |

| Min.fullloadingdiameter of coiled plate | 500mm |

| Rolling speed | 4.5m/min |

| Motor power | 11kw |

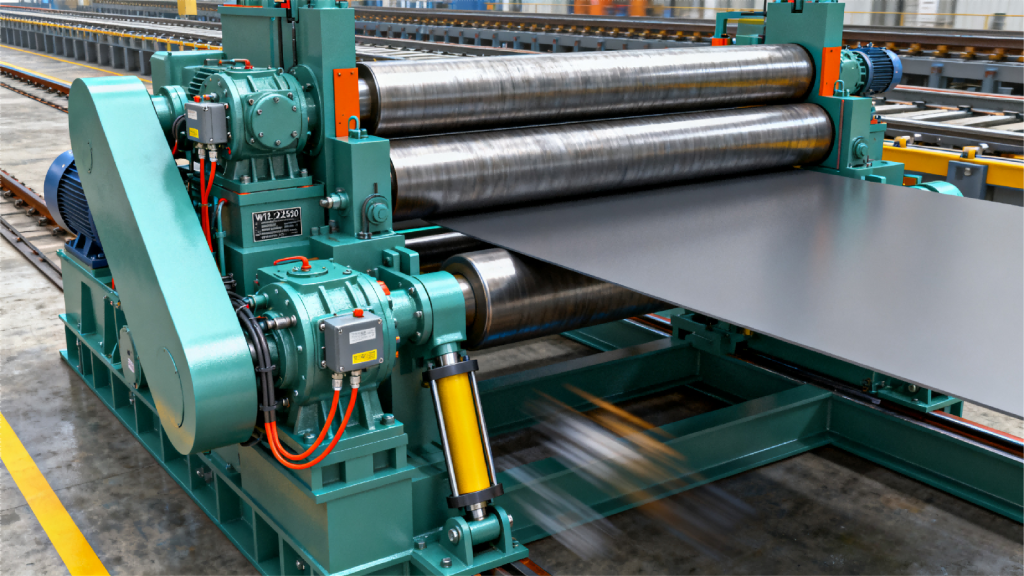

Superior Forming Precision

Features a 4-roll structure (upper main drive + lower/side auxiliary rolls) for stable plate clamping and uniform force distribution. Ensures accurate end pre-bending and rounding in one pass, reducing rework.

Efficient Power Transmission

Driven by hydraulic motors (upper roll as main drive, optional dual upper/lower roll drive) for strong torque. Hydraulic cylinder-controlled lower roll lifting enables fast plate clamping, boosting production speed.

Stable & Durable Operation

Side rolls move along arc-shaped frame guide rails via hydraulic system, ensuring smooth motion and consistent forming quality. Robust build handles 12mm-thick, 2500mm-wide plates reliably for long-term use.

Versatile Application

Ideal for rolling carbon steel, stainless steel, and non-ferrous metal plates. Suitable for industries like machinery manufacturing, pressure vessels, and construction – meets diverse small-to-medium batch production needs.