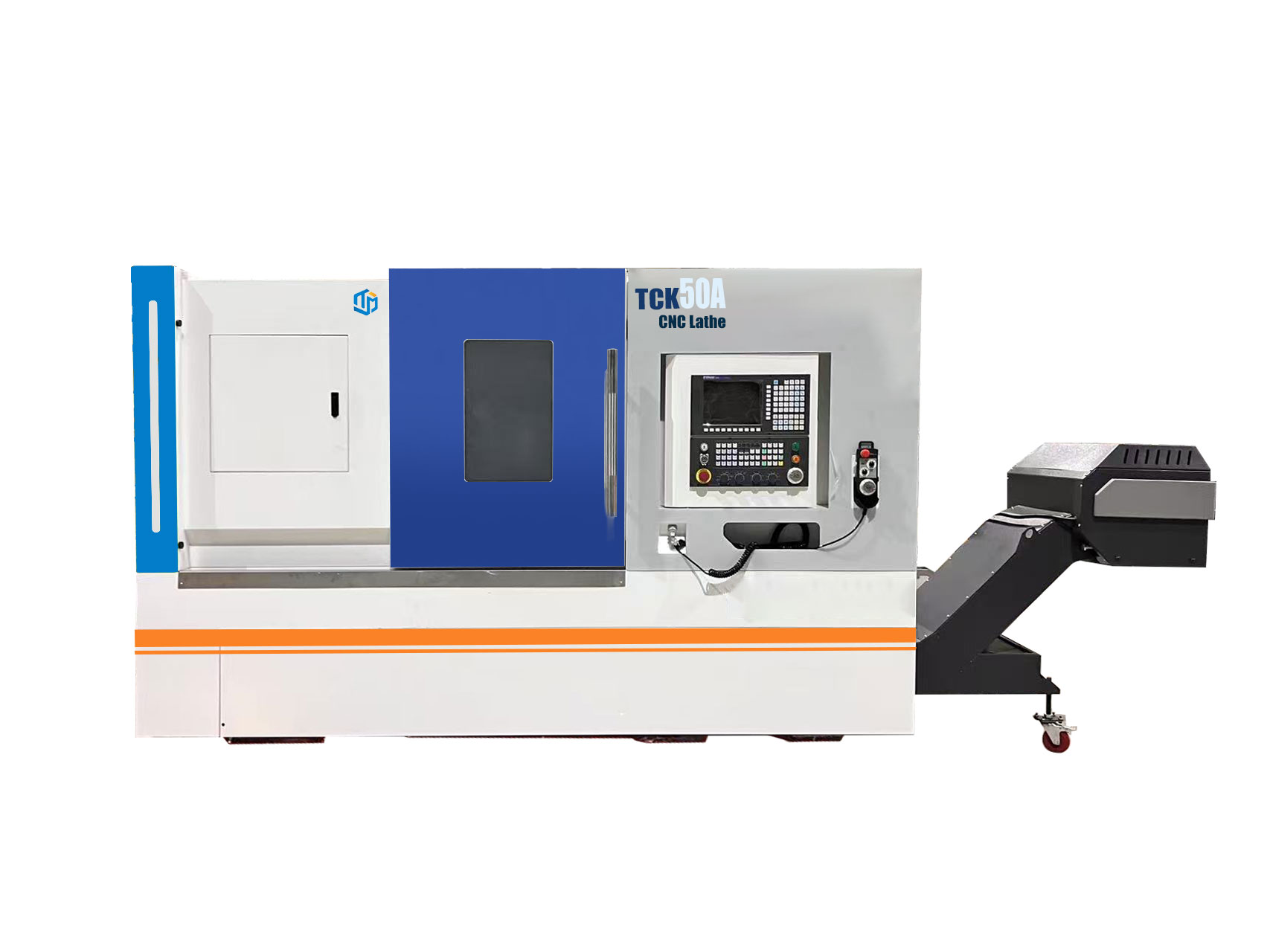

CK6180 is a heavy duty cnc lathe that offers the ideal choice for handling heavy machining tasks. It features a robust and durable structure, making it suitable for various large-scale workpiece machining needs. With advanced CNC technology and a high-performance drive system, heavy duty cnc lathe CK6180 achieves high precision and efficiency in machining operations. Equipped with a stable and reliable spindle system and a rigid bed, it can withstand high loads and frequent cutting, ensuring consistent machining quality. Whether in aerospace, energy, automotive manufacturing, or heavy industries, CK6180 excels in handling a wide range of heavy machining tasks. By choosing CK6180, you can expect outstanding machining performance and reliable results, enhancing your production capabilities and competitiveness.

| Specification Capacity | CK6180 |

| Chuck size | 12″ |

| Max.swing dia over bed | 800mm |

| Max.swing dia over slide | 560mm |

| Distance between center | 1000/1500/2000/3000mm |

| Width of bed | 400mm |

| Spindle | |

| Spindle speed range | 45-180/180-750/600-1600rpm |

| Spindle bore | Φ82mm,*Φ105mm |

| Max.dia of through-hole | Φ70mm,*Φ90mm |

| Spindle nose | A2-8(*105mmforC-11) |

| Spindle taper | Φ90mm1:20*105mmfor120mm1:20 |

| Axis | 310mm |

| Xaxis travel | 1000/1500/2000/3000mm |

| Zaxis travel | |

| XZ axis rapid traverse | 6/8m/min |

| Turret type | Electrictype |

| No of tool stations | 4,*6,*8position |

| Max.section of tool | 25x25mm |

| Tailstock | |

| External diameter | Φ75mm |

| Travel of tailstock quill | 150mm |

| Taper of talstock quill | MT5 |

| Motor | |

| Spindle motor power | 11kw |

| Coolant pump power | 250w |

| Machine Dimensioris | |

| Overal dimension (L×W×H) | 2750/3250/3700/4600x1800X2000mm |

| Packing size(L×W×H) | 2900/3400/3800/4700x2000x2250mm |

| N.W | 2800/3000/3500/3900kg |

| GW | 3000/3300/3700/4400kg |

Massive Machining Capacity

Handle hefty workpieces up to 800mm in diameter. With optional turning lengths stretching to 6000mm, it’s perfect for those gargantuan shafts and cylinders. Ideal for heavy machinery, power generation, and oil & gas industries.

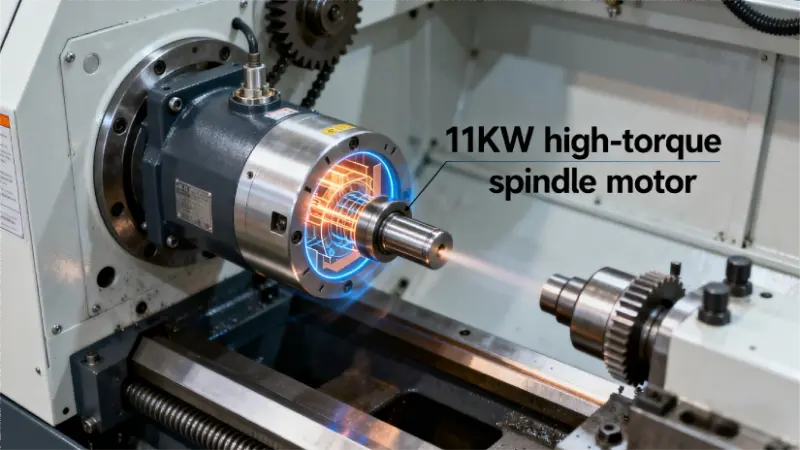

Robust Powerhouse

Equipped with an 11kW high-torque spindle motor. It slices through steel, cast iron, and alloys like a hot knife through butter, reaching speeds up to 1600r/min for rapid material removal.

Rock-Solid Precision

Built on a reinforced cast-iron bed with hardened guideways. This ensures rock-stable performance, maintaining IT7-level accuracy even under the most strenuous loads.

Versatile Operations

The multi-station turret takes on complex tasks—turning, threading, grooving, and facing—all in one seamless setup. Adapt to diverse job requirements with ease.

User-Friendly Interface

A 10.4″ touchscreen CNC system simplifies programming. New operators can get up to speed quickly, slashing training time and getting you production-ready faster.

Durable for the Long Haul

Constructed with heavy-duty components, it’s designed for non-stop industrial operation. Spend less time on maintenance and more time on maximizing output.