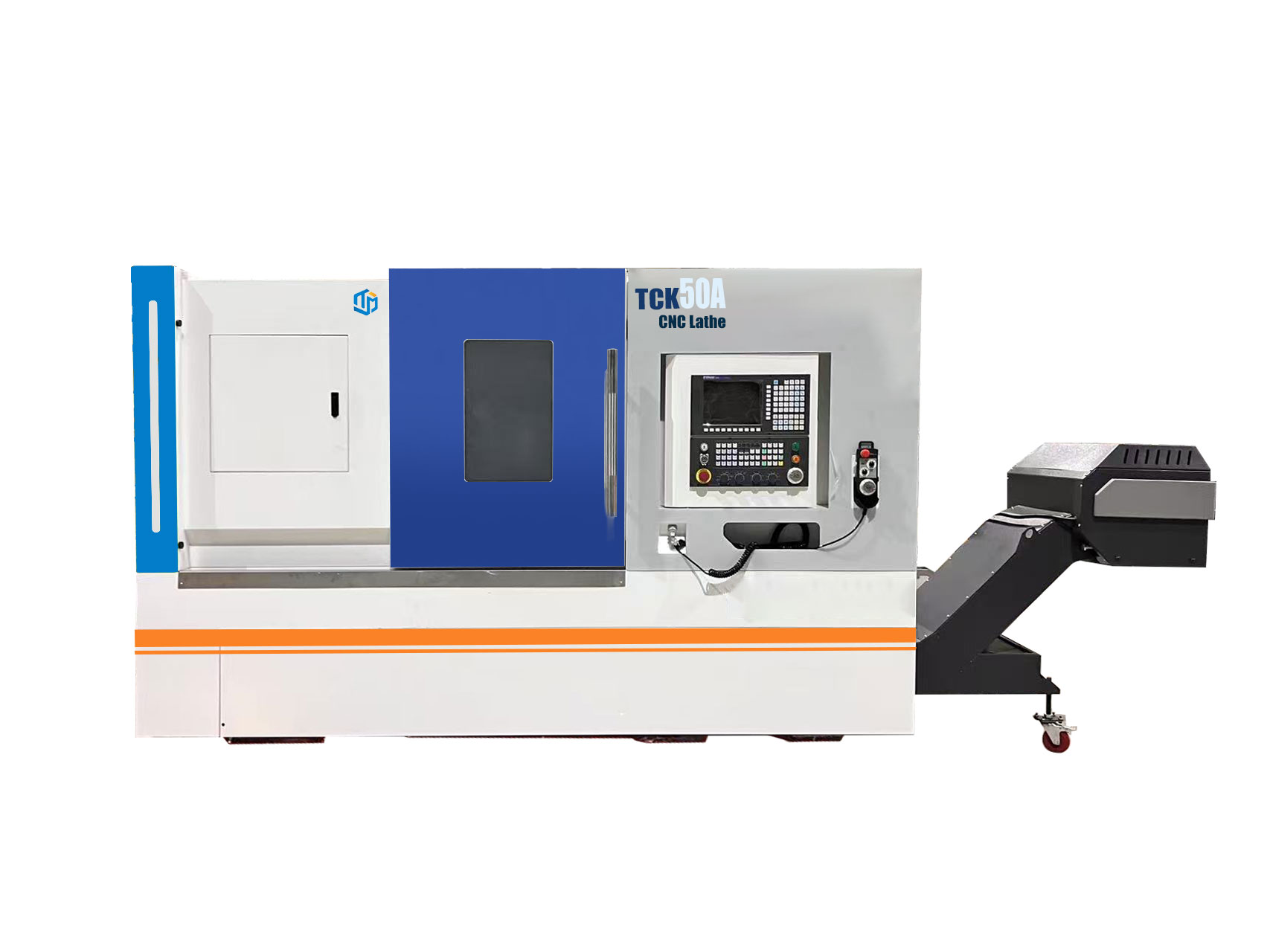

The TCK50A CNC lathe is a brand-new product designed and manufactured to meet market demands and developmental needs. Its key performance metrics reach internationally advanced levels, delivering exceptional precision and stability. Featuring a high-rigidity structure for heavy-cutting feed rates, this machine offers customers a high-efficiency, low-cost, high-quality solution.

| Specification | TCK50-500 |

| Capacity | |

| Max. swing dia. over bed | φ560mm |

| Max. length of workpiece | 550mm |

| Max. turning dia. | Φ430mm (Disc parts) Φ310mm (Shaft parts) |

| Max. turning dia. | 8”-480(10”-460) |

| Max. swing dia. over slide | φ310mm |

| Max. bar diameter | φ50mm |

| Spindle | |

| Spindle speed range | 50~3000r/min |

| Spindle bore | φ65mm |

| Spindle nose | A2-6 |

| Max. spindle output torque | 150Nm |

| Spindle motor | 11kw |

| Hydraulic chuck size | 8”/10″ |

| Axis | |

| X axis travel | 220mm |

| Z axis travel | 560mm |

| X axis rapid traverse | 30m/min |

| Z axis rapid traverse | 30m/min |

| Turret | |

| No. of tool station | 8 position |

| Tool shank size | 25×25mm |

| Boring tool shank size | φ40/φ32 |

| Tailstock | |

| Tailstock travel | 350mm |

| Taper of tailstock quill | MT5 |

| Max. Loading Capacity | |

| Disk parts | 200kg |

| Shaft parts | 500kg |

| Machine Dimensions | |

| Overal dimension(L x W x H) | 2775×1842×1866mm |

| Machine weight | 3650kg |

Turret System Common configurations include 8-station or 12-station hydraulic turrets. Optional servo turrets, power turrets, or turrets from Taiwanese brands are available.

The machine tool adopts an integrated mechanical, electrical, and hydraulic structure with a compact and rational overall layout, facilitating maintenance and servicing. It features high efficiency, precision, and rigidity.

This machine tool is capable of machining shaft-type and disc-type components, turning threads, arcs, cones, and the inner and outer surfaces of rotary bodies, enabling efficient, high-volume, and high-precision machining of rotary parts.

The spindle speed refers to the rotational speed range under standard configuration. When installing other configurations of chucks, fixtures, or main motors, please note the maximum rotational speed limit of the selected chuck or fixture. The machine tool’s maximum torque remains constant, but as the cutting diameter increases, the achievable cutting parameters decrease accordingly. Therefore, machine tool processing parameters should be adjusted based on the workpiece dimensions.