The X5750 ram-type milling machine stands as a testament to precision engineering and versatile performance, designed to elevate your manufacturing capabilities.

| Specification | X5750 |

| Worktable | |

| Table size | 500×1600mm |

| Tslot sze(N×W×D) | 5-18x80mm |

| Table travel (X/Y/Z) | 1200×700x500mm |

| Swivel Table | 360° |

| Feed | |

| Table feed(X/Y/Z) | 10-1000/10-1000/5-500mm/min |

| Table rapid speed | 2200/2200/1100mm/min |

| Feeding motor toque(X/Y/Z) | AC servo motor:1818/27Nm |

| Spindle | |

| Spindle taper | ISO50 |

| Distance between spindle nose and table surface | 50-550mm |

| Distance between spindle and am | 45-745mm |

| Spindle speed range | (27steps)30-2050rpm |

| Main motor power | 7.5kw |

| Machine weight | |

| Max loading capacity | 1500kg |

| N.w | 4500kg |

| Overall ize | 2625×2460×2080mm |

Strong Stability

Built with a robust cast iron frame and reinforced ram, it resists vibration even under heavy cutting, ensuring consistent accuracy and longer tool life.

Wide Versatility

Multi-axis design + adjustable spindle speeds handle diverse tasks (face milling, slotting, gear cutting) and materials (steel, aluminum, composites) with ease.

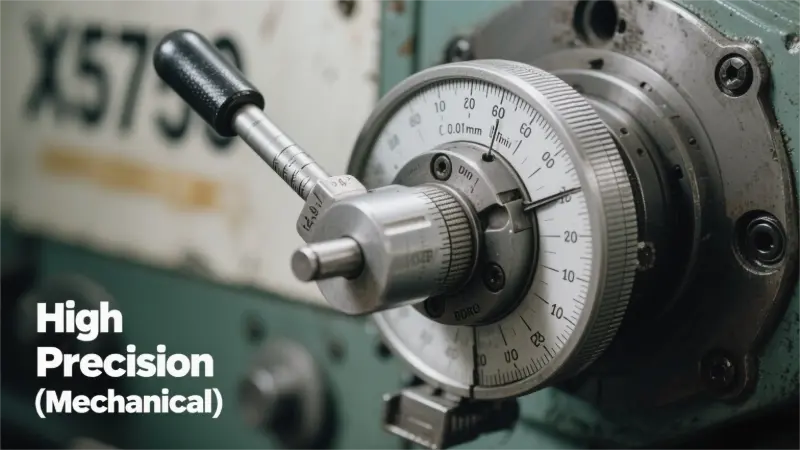

High Precision

Equipped with high-precision ball screws, servo feeds, and a digital readout (DRO) system, it achieves micron-level positioning and repeatable results for batch production.

Easy & Efficient Operation

Intuitive control panel + ergonomic layout reduce setup time; powerful motor + optimized cooling support non-stop work.

Durable & Cost-Saving

High-quality components (sealed bearings) lower maintenance needs and downtime; one machine replaces multiple devices, cutting operational costs.