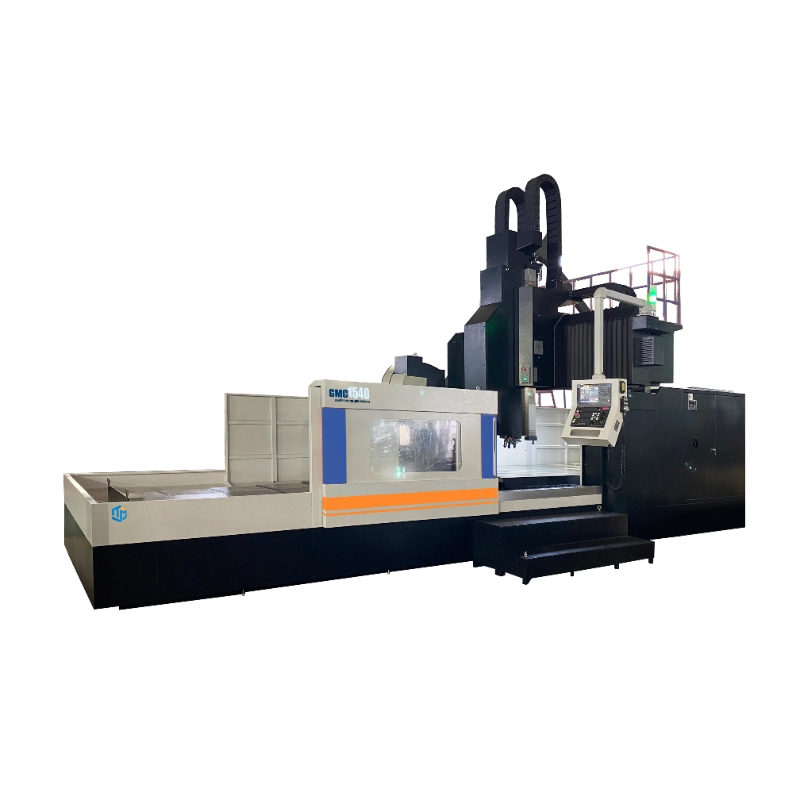

This machine is suitable for miling, boring, diriing,threading, etc. Machining ferrous and non ferrous metals, it can finished variousprocess with only once install the work piece, ensure the quality of products and production efficiency.

| Specification | GMC1540 |

| Worktable | |

| Worktable size (L×W) | 4000×1500mm |

| T-slots size (N×W×D) | 9-22×160mm |

| Travel | |

| X/Y/Z axis travel | 4100/1650/800mm |

| Capacity | |

| Distance from spindle nose to worktable surface | 160-960mm |

| Distance between two columns | 1650mm |

| Spindle | |

| Spindle taper | BT50 |

| Spindle power | 15/18.5kw |

| Max. spindle speed | 6000rpm |

| Spindle torque | 143N·m |

| Feed | |

| Rapid feed speed (X/Y/Z) | 10/10/10m/min |

| Ball screw (diameter+lead) | |

| X/Y/Z axis ball screw | 8020/5016/5016 |

| X/Y/Z guideway type | X/Y:roller linear guideways, Z:box guideway |

| Tool magazine | |

| Tool magazine capacity | 24T |

| Max. length of tool | 350mm |

| Tool change time (T-T) | 3s |

| Positioning accuracy (GB standard) | |

| Positioning accuracy(X/Y/Z) | 0.03mm |

| Re-positioning accuracy(X/Y/Z) | 0.018mm |

| Machine dimension | |

| L×W×H | 10800×5800×5000mm |

| Machine weight | |

| Max. loading of worktable | 8t |

| N.W | 28t |

Extended Machining Capacity: Boasting a massive worktable (1500×4000mm) and a vertical Z-axis stroke of 800mm, the GMC1540 handles extra-large components with ease. The reinforced double-column gantry structure, crafted from high-tensile cast iron, ensures minimal deflection under heavy loads, maintaining stability during high-speed cutting.

High-Power Performance: Equipped with a 22kW spindle motor (optional 30kW) and speeds up to 6000rpm, it efficiently machines tough materials like alloy steel and titanium. The servo-driven feed system achieves rapid traverse rates (X/Y/Z: 20/20/15m/min), reducing non-cutting time and boosting throughput by 25% for batch production.

Advanced Precision Control: Featuring a Heidenhain/FANUC CNC system with 5-axis interpolation capability, the machine delivers positioning accuracy of ±0.005mm and repeatability of ±0.003mm. The integrated laser tool setter and workpiece probe enable automated calibration, eliminating manual errors and ensuring consistent part quality.

Smart Factory Integration: The 19-inch industrial touchscreen HMI supports seamless CAD/CAM data transfer and remote diagnostics via OPC UA protocol. Automatic chip removal, coolant recycling, and energy-saving mode (standby power ≤5kW) optimize workshop efficiency and reduce operational costs.

Applications:

Perfect for machining large-format structural parts, turbine components, shipbuilding sections, and precision dies. Its versatility makes it a cornerstone for manufacturers requiring both size and precision in high-volume production.