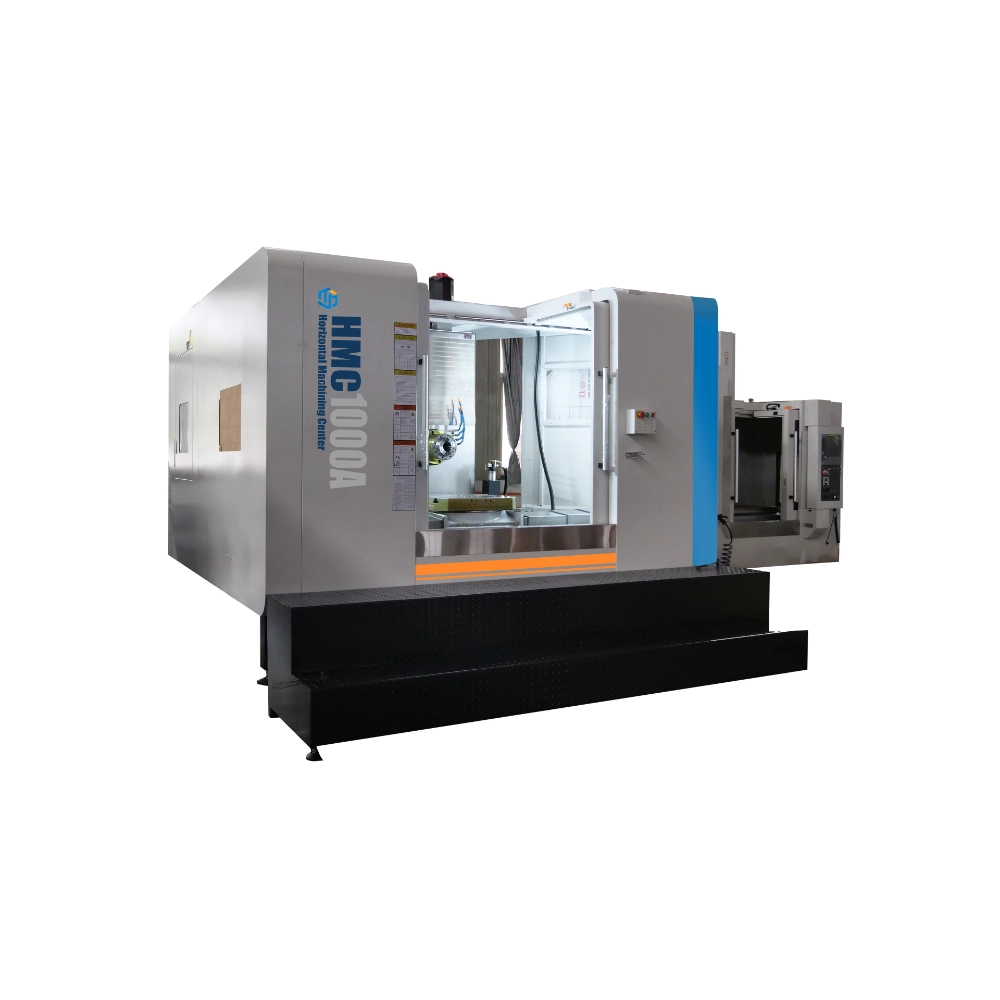

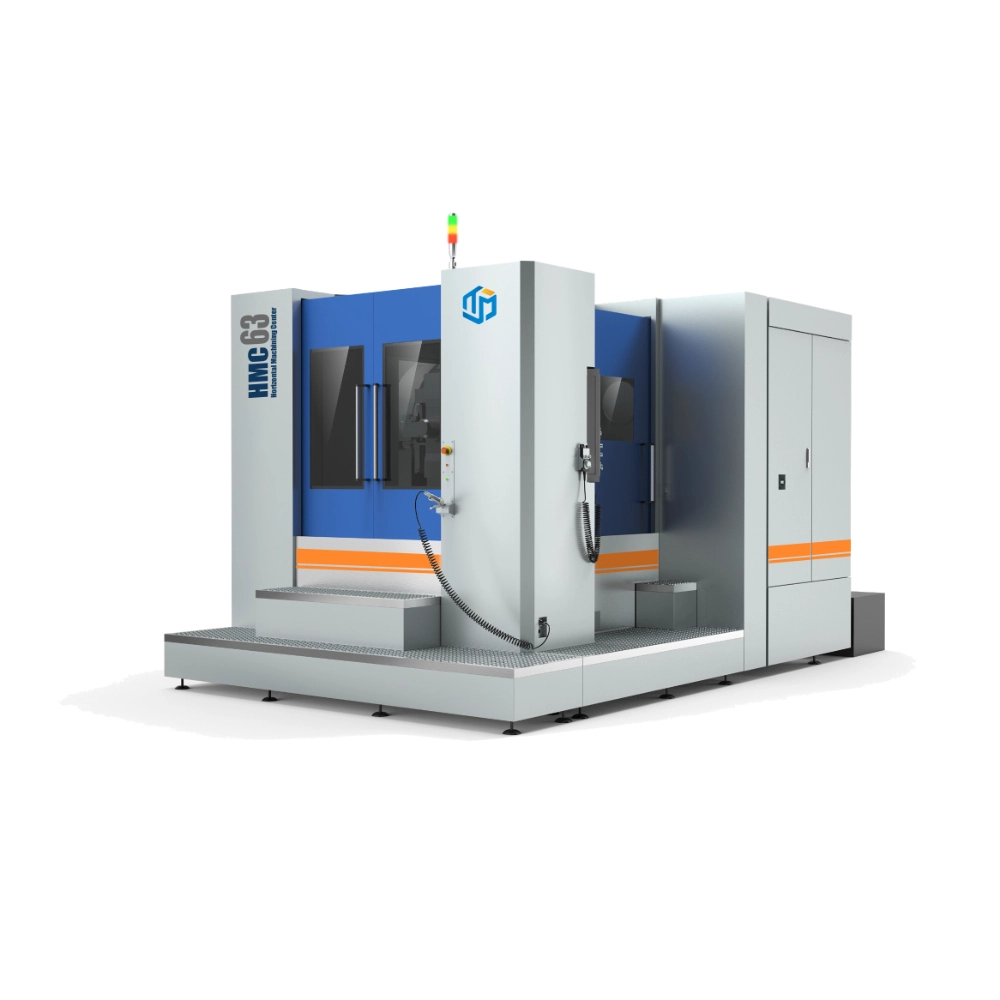

HMC1000A series is featuring high rigidity, heavy cutting ability and high operability. The strong base column construction has optimally-placed ribs to counter chatter and twisting during heavy cutting. With 3 axes roller linear guideway and wide area motor, this vertical machining center can perform heavy cutting and high speed machining with high torque from low to high speed.

| Specification | HMC1000A |

| Worktable | |

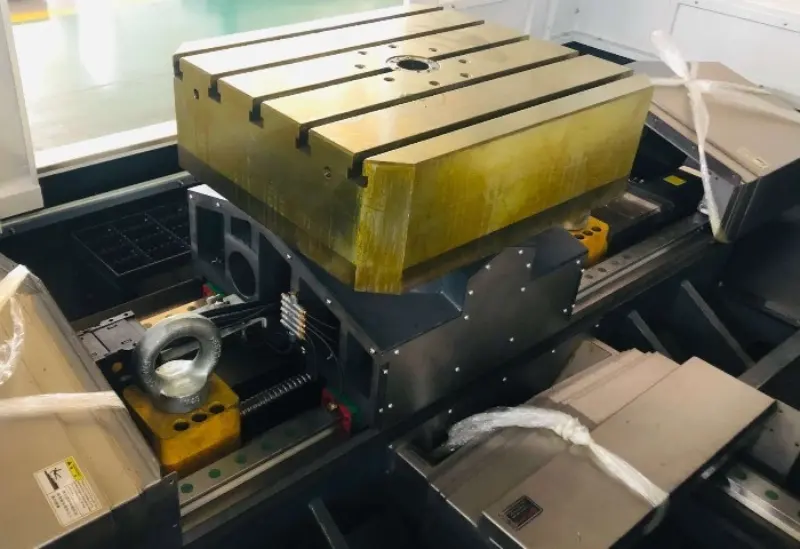

| Worktable size (W×L) | 1000×1000mm |

| Workpiece clamping type | 24×M16 |

| Changing time of worktables | / |

| Rotary diameter of workpiece | 1750mm |

| Travel | |

| X/Y/Z axis | 1600/1000/1000mm |

| Distance from spindle center to worktable surface | 120-1120mm |

| Distance from worktable center to spindle nose | 200-1200mm |

| Spindle | |

| Spindle hole taper | BT50 |

| Spindle speed range | 6000rpm |

| Drive type (Spindle) | Belt type |

| Spindle power | 15/18.5kw |

| Feed | |

| X/Y/Z axis rapid feed speed | 24/24/24m/min |

| B axis rapid feed speed | 10m/min |

| Tool magazine | |

| Tool magazine model | Manipulator |

| Capacity | 24T |

| Max. tools weight | 15kg |

| Max. tools length | 300mm |

| Tool change time | 5.5s |

| Accuracy(National standard) | |

| Positioning accuracy (X/Y/Z) | ±0.012mm |

| Re-positioning accuracy(X/Y/Z) | ±0.008mm |

| B axis division accuracy | 12’’ |

| B axis re-division accuracy | 6’’ |

| Machine Size | |

| L×W×H | 5600x4075x3180mm |

| Machine weight | |

| Max. loading of worktable | 1500kg |

| Machine weight | 18000kg |

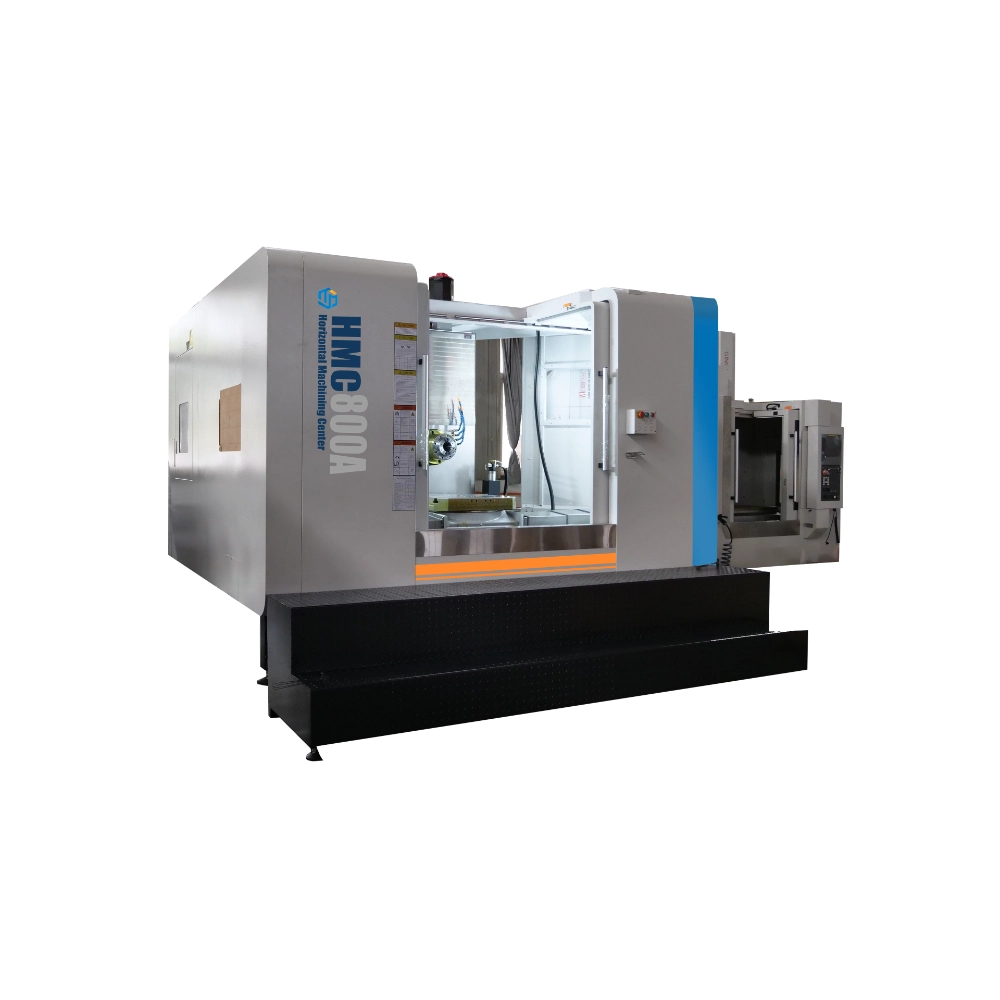

Inverted T-shaped bed

Adopts a “┻”-shaped column structure for high rigidity and rapid traverse.

All machine components are designed using finite element analysis.

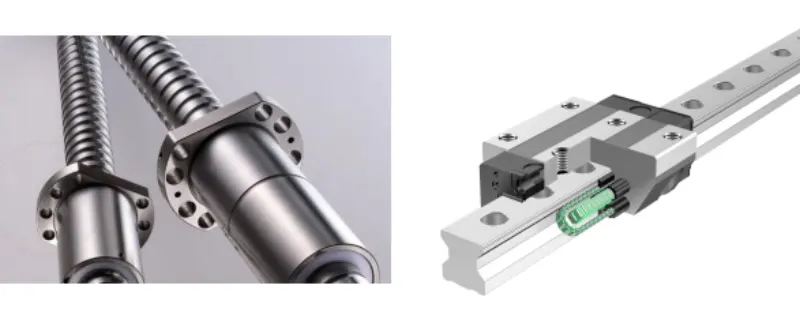

High-precision double-nut ball screw

Ensures heavy-duty cutting, ensures machining accuracy, and extends screw life. Three-axis rapid traverse: 24/24/24 m/min

Ultra-high rigidity and high precision

Low-noise roller-type linear guides ensure high machine stability

Axes Driving :

TOP TAIWAN brand Ball screw & linear guideway

Double nuts C3 level grinded ball screws.Screw diameter* pitch: 4012/4012/50*12

Roller type linear rails for three axis.The rail size and model: RGW45/RGH45/RGW55.Three axis Slide load block quantity: 4/4/4.

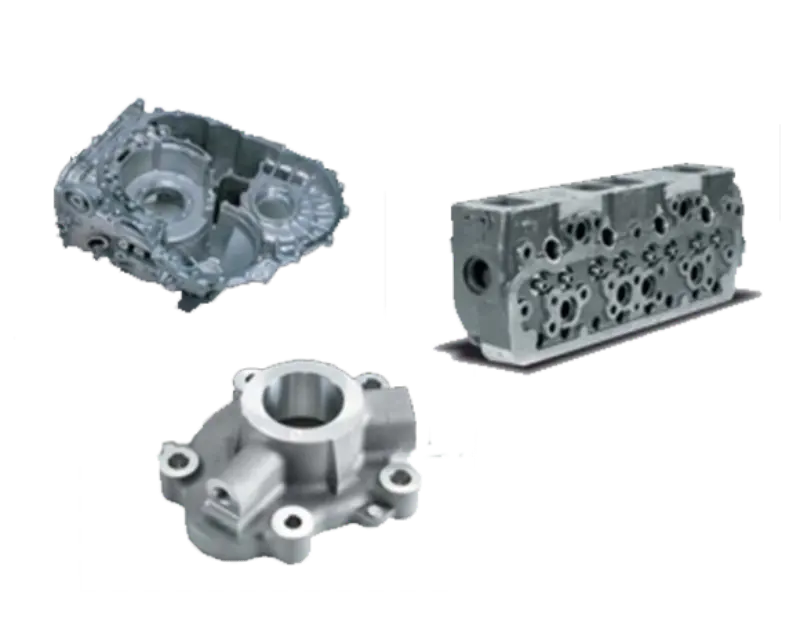

Application Industries

Suitable for mass production of products with complex shapes and high precision requirements, especially for machining housings and complex structural parts, such as in the automotive, aerospace, marine, and power generation industries.