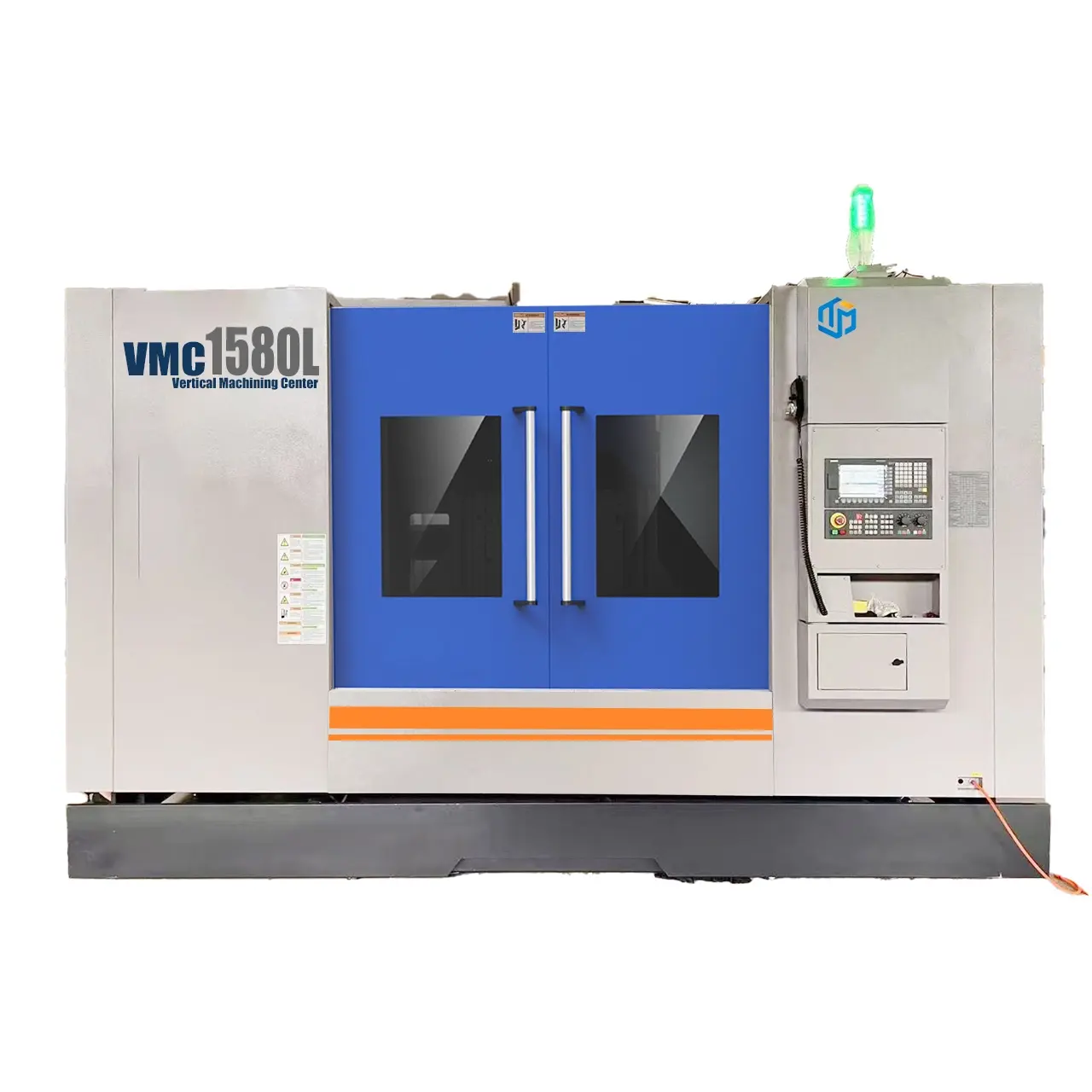

Main Features:

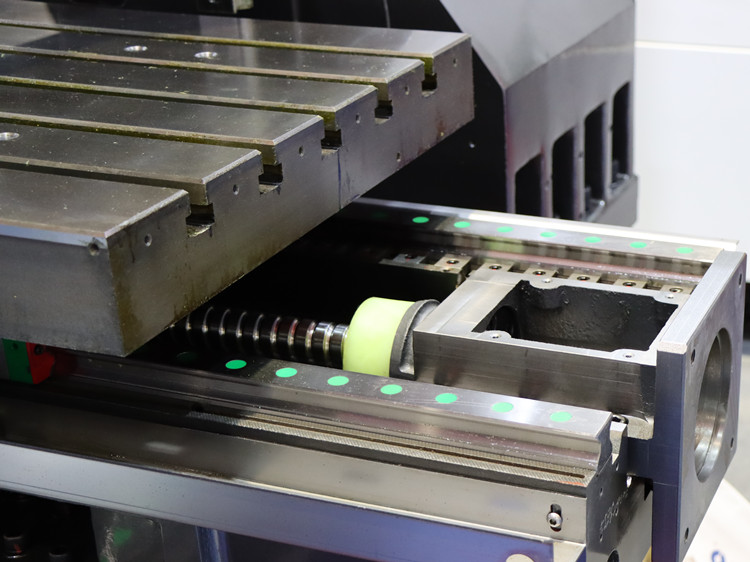

Each of the 5 axes is equipped with precision-grade lead screws. These screws are combined with nut preloading and pre-stretching processes, which proactively eliminate backlash and reduce temperature elevation. This ensures the machine maintains stable positioning and reliable repeatability accuracy during operation. Furthermore, the X, Y, and Z axes utilize precision linear guide rails. This design effectively controls both positioning accuracy deviations and machining errors, thereby enabling the machine to deliver high-precision performance while extending its overall service life.