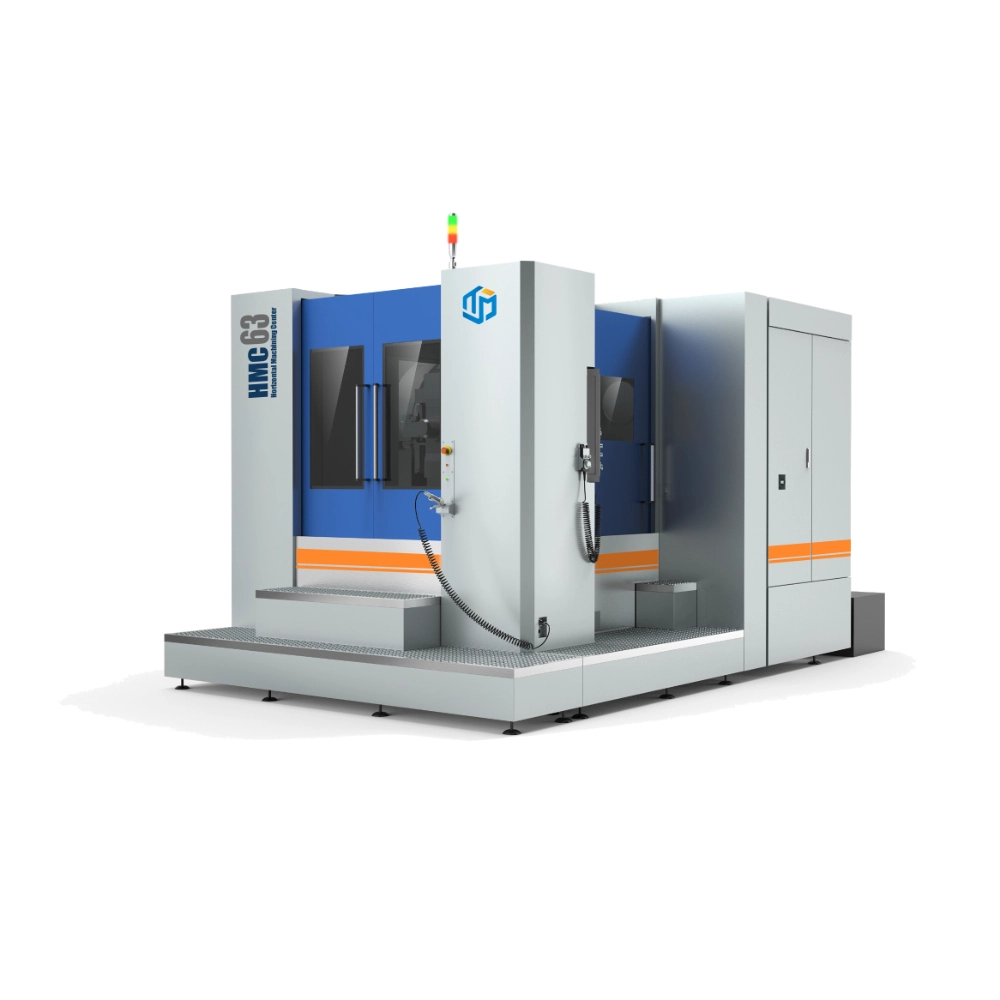

For manufacturers aiming to elevate precision, boost throughput, and tackle diverse production demands, the HMC63 Horizontal Machining Center delivers uncompromising performance. Built on a robust positive T-structure and engineered for long-term reliability, it’s tailored to handle high-volume batch production, heavy-duty machining, and complex part manufacturing—serving as a cornerstone for industries such as automotive, aerospace, energy, and heavy equipment.

Core Advantages: Engineered to Meet Your Production Goals

| Specification | HMC63(Positive T) |

| Worktable | |

| Worktable size (W×L) | 630×700mm |

| Workpiece clamping type | 24×M16 |

| Changing time of worktables | / |

| Rotary diameter of workpiece | 1400mm |

| Travel | |

| X/Y/Z axis | 1050/750/900 |

| Distance from spindle center to worktable surface | 120-870mm |

| Distance from worktable center to spindle nose | 130-1030mm |

| Spindle | |

| Spindle hole taper | BT50 |

| Spindle speed range | 5300rpm |

| Drive type (Spindle) | Belt type |

| Spindle power | 15/18.5kw |

| Feed | |

| X/Y/Z axis rapid feed speed | 32/32/32m/min |

| B axis rapid feed speed | 10m/min |

| Tool magazine | |

| Tool magazine model | Manipulator |

| Capacity | 24T |

| Max. tools weight | 18kg |

| Max. tools length | 550mm |

| Tool change time | 5.5s |

| Accuracy(National standard) | |

| Positioning accuracy (X/Y/Z) | ±0.010mm |

| Re-positioning accuracy(X/Y/Z) | ±0.006mm |

| B axis division accuracy | 10’’ |

| B axis re-division accuracy | 5’’ |

| Machine Size | |

| L×W×H | 5000×3720×3000mm |

| Machine weight | |

| Max. loading of worktable | 1200kg |

| Machine weight | 12000kg |

“Vibration-free machining,” “high rigidity horizontal machining center,” “precision CNC cutting.”

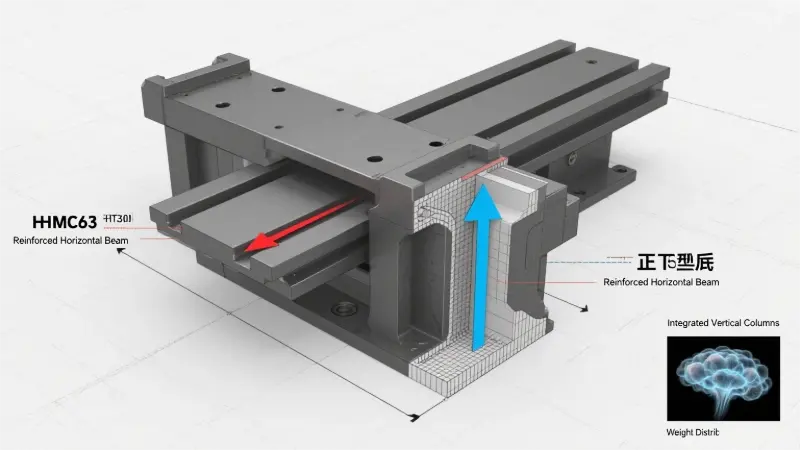

At the core of the HMC63 is its positive T-shaped bed, crafted from high-grade cast iron HT300. This innovative design features a reinforced horizontal base beam seamlessly integrated with vertical support columns, forming a balanced load-bearing framework. By distributing weight evenly across the machine, it effectively minimizes vibration even during high-speed cutting or heavy material removal tasks, such as machining cast iron, alloy steel, or titanium.

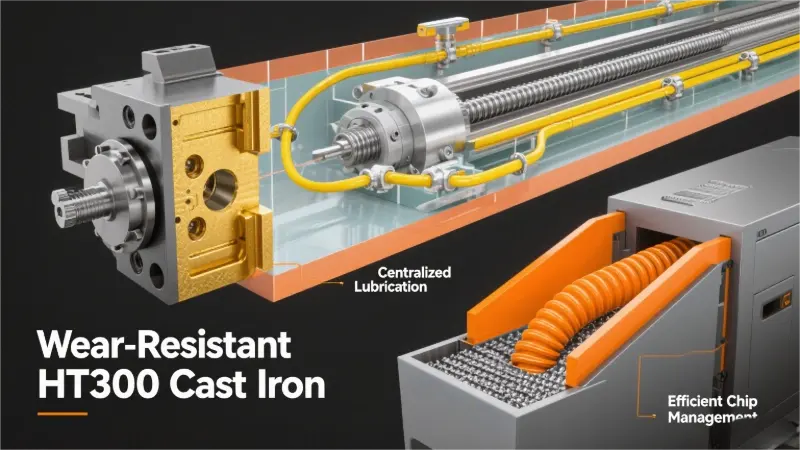

“High-precision horizontal machining,” “stable spindle performance,” “CNC machining accuracy.”Hardened Rectangular Guideways: These low-friction, wear-resistant guides on the X/Y/Z axes reduce backlash, guaranteeing stable motion paths—essential for multi-axis contouring of complex parts like gear housings or hydraulic valves.

High-Stability Spindle: The optional 10,000 RPM spindle is mounted on a rigid column integrated with the positive T-frame, minimizing axial runout. Combined with powerful torque (up to 800 N·m), it effortlessly handles both high-speed finishing and heavy roughing operations.

Why it matters: Ensures dimensional consistency across batches, a critical factor for industries like aerospace and automotive where part interchangeability is non-negotiable.

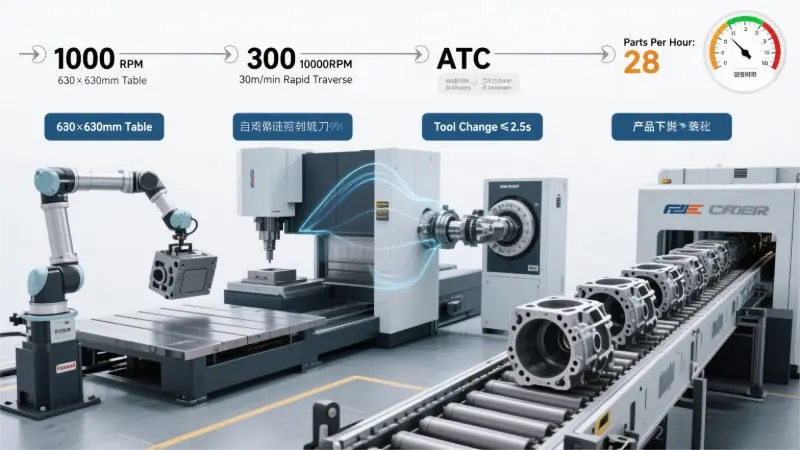

“Fast CNC machining cycles,” “high-productivity horizontal center,” “reduced downtime manufacturing.”In high-volume manufacturing, every second counts—and the HMC63 is engineered to keep spindles running and parts flowing efficiently:

Fast Traverse Speeds: With X/Y/Z axes rapid traverse reaching up to 30m/min, non-cutting time between operations is drastically slashed.

High-Speed Automatic Tool Changer (ATC): Equipped with a 24/30-tool magazine, tool change times are ≤2.5 seconds, minimizing idle time and maximizing spindle utilization.

Why it matters: Increases parts-per-hour output—ideal for producing engine blocks, hydraulic manifolds, or gearboxes—and helps meet tight production deadlines with ease.

“Heavy-duty CNC machining,” “versatile horizontal center,” “large part machining solutions.”No two production runs are identical, and the HMC63 adapts seamlessly to your varying needs:

Generous Worktable Capacity: The 630×630mm table, supported by the stable positive T-structure, can handle a maximum load of 1,000kg, easily accommodating large and heavy workpieces such as industrial valves and pump housings.

Broad Material Compatibility: It efficiently machines a wide range of materials, including steel, aluminum, titanium, and composites, backed by robust spindle power to tackle tough materials.

Why it matters: Eliminates the need for multiple machines, enabling you to process everything from small precision components to large, complex 箱体类 (box-type) or 盘类 (disk-type) parts.

Durability & Low Total Cost of Ownership.Invest in a machine that stands the test of time with minimal maintenance hassle:

Heavy-Duty Build: The HT300 cast iron positive T-shaped bed resists wear, deformation, and thermal expansion over years of continuous use, maintaining structural integrity even under heavy loads.

Smart Maintenance Features:

An automatic centralized lubrication system for guides and screws extends compon