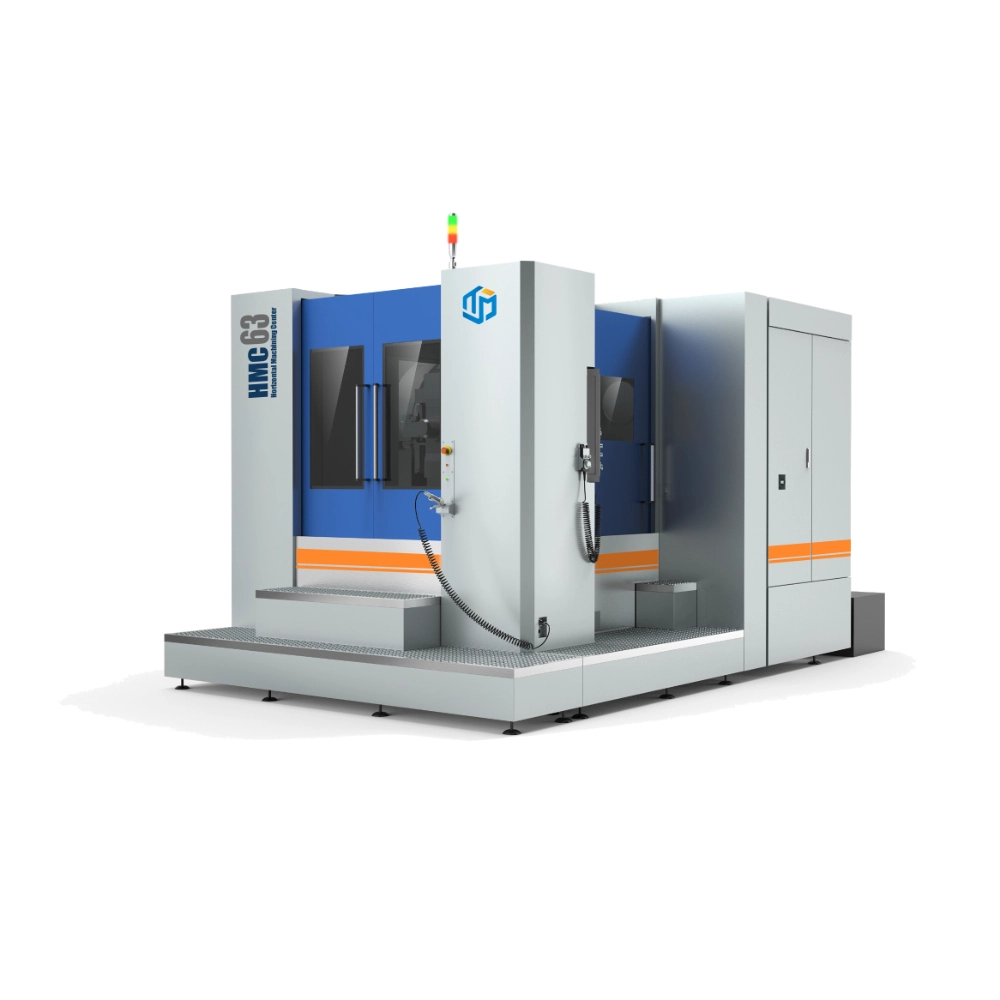

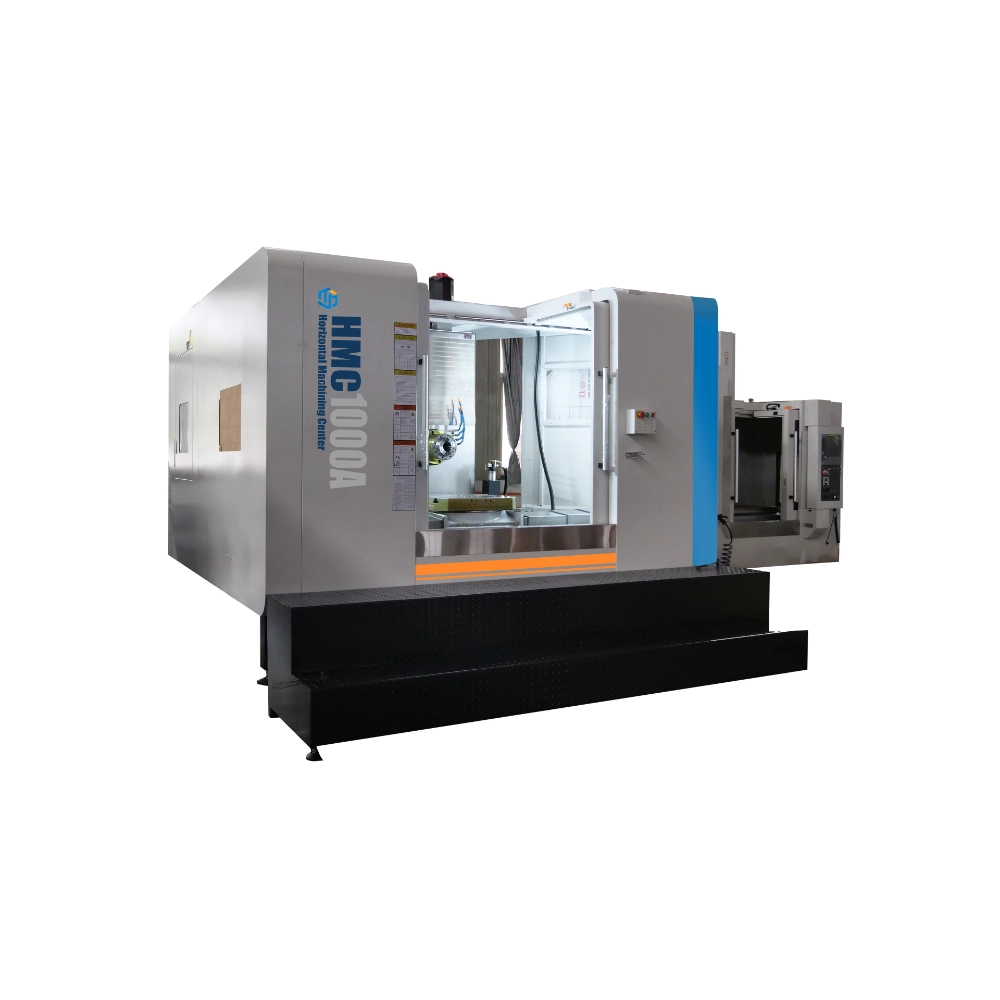

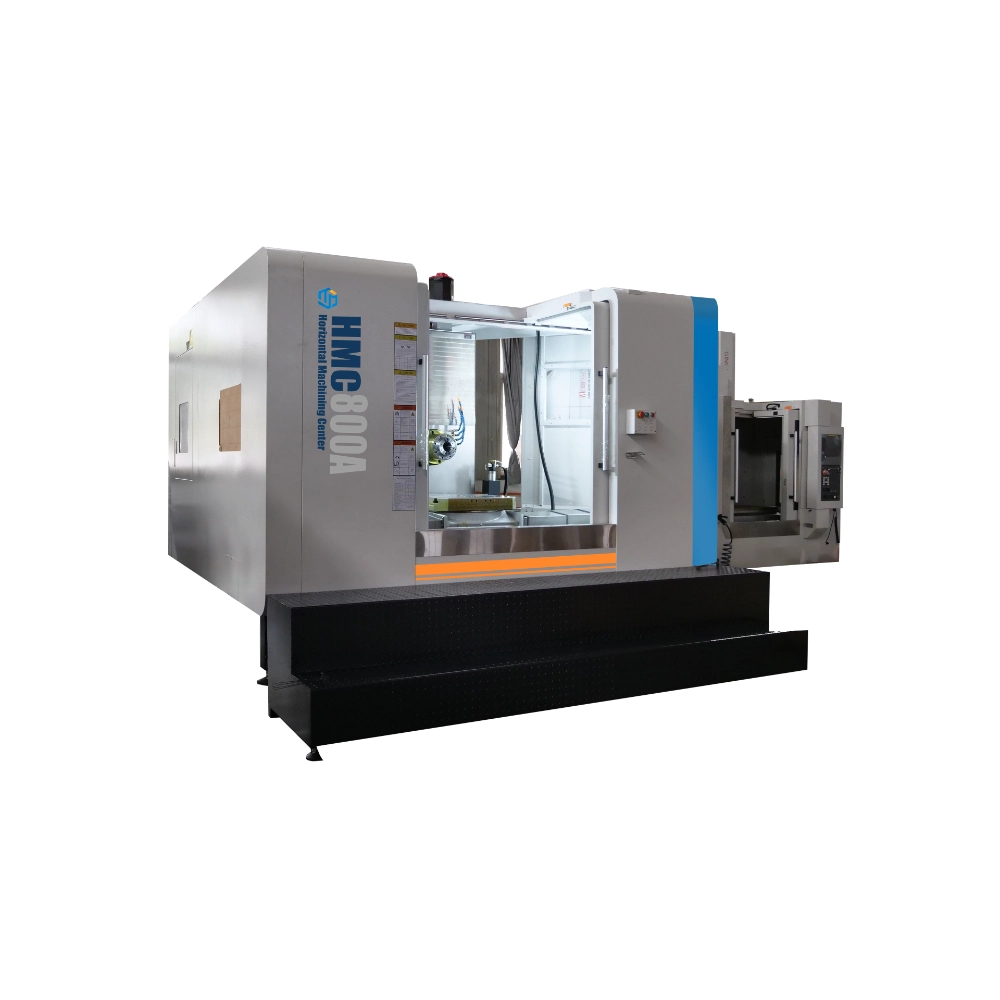

Designed for precision, efficiency, and versatility in heavy-duty machining, the HMC630A stands out with its innovative inverted T-structure. Below, we break down its key advantages, paired with visual insights to highlight its performance.

| Specification | HMC630A(Inverted T) |

| Worktable | |

| Worktable size (W×L) | 630×700mm |

| Workpiece clamping type | 24×M16 |

| Changing time of worktables | / |

| Rotary diameter of workpiece | 1380mm |

| Travel | |

| X/Y/Z axis | 1050/750/900 |

| Distance from spindle center to worktable surface | 120-870mm |

| Distance from worktable center to spindle nose | 130-1030mm |

| Spindle | |

| Spindle hole taper | BT50 |

| Spindle speed range | 5300rpm |

| Drive type (Spindle) | Belt type |

| Spindle power | 15/18.5kw |

| Feed | |

| X/Y/Z axis rapid feed speed | 24/24/24m/min |

| B axis rapid feed speed | 10m/min |

| Tool magazine | |

| Tool magazine model | Manipulator |

| Capacity | 24T |

| Max. tools weight | 15kg |

| Max. tools length | 350mm |

| Tool change time | 5.5s |

| Accuracy(National standard) | |

| Positioning accuracy (X/Y/Z) | ±0.010mm |

| Re-positioning accuracy(X/Y/Z) | ±0.006mm |

| B axis division accuracy | 10’’ |

| B axis re-division accuracy | 5’’ |

| Machine Size | |

| L×W×H | 4800x3200x2950mm |

| Machine weight | |

| Max. loading of worktable | 1200kg |

| Machine weight | 12000kg |

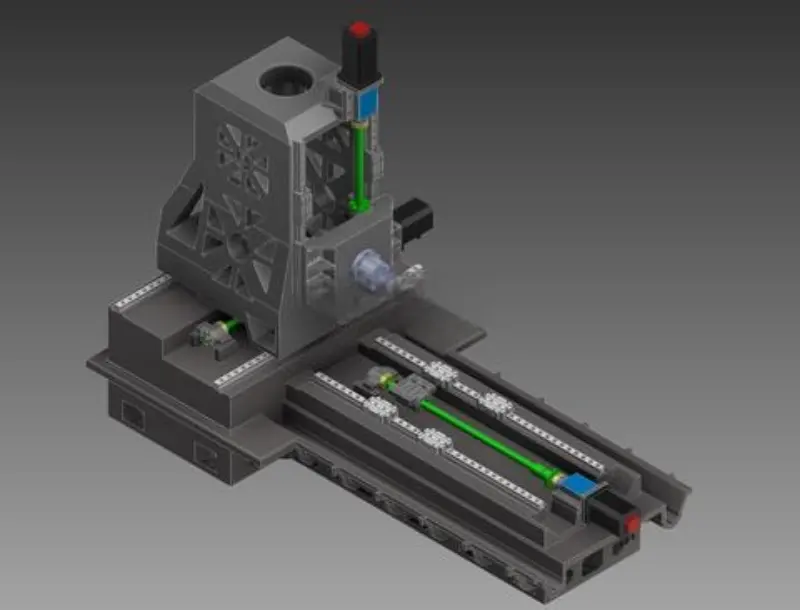

Superior Structural Rigidity: Reduced Vibration for Precision

The inverted T-structure is the foundation of the HMC630A’s stability. This layout features a wide, low-profile base with reinforced vertical columns, distributing weight evenly across the machine bed.

Why it matters: Rigidity minimizes vibration during high-speed cutting or heavy material removal (e.g., machining cast iron or alloy steel). Reduced vibration directly translates to tighter tolerances (up to ±0.001mm) and smoother surface finishes (Ra ≤ 1.6μm).

Visual tip: Include a cross-sectional diagram of the bed and column, “Reinforced Ribs” “Symmetrical Weight Distribution” to show stress dispersion.

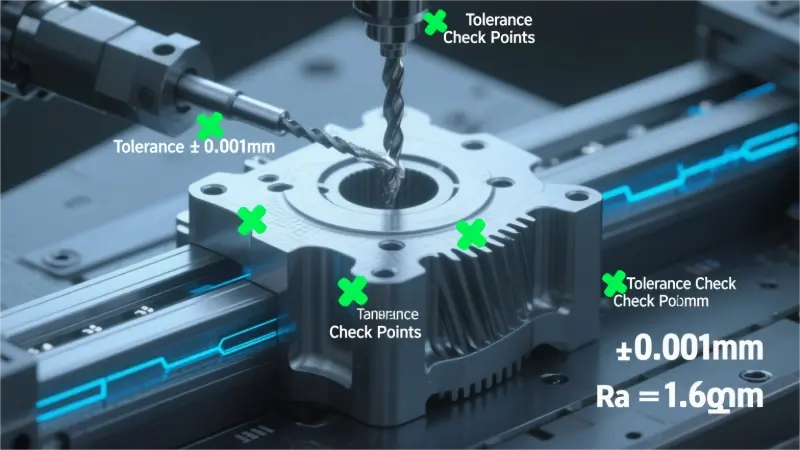

Enhanced Machining Accuracy: Stable Motion Paths

The inverted T-design pairs with high-precision components to ensure consistent accuracy:

Guides & Feed Systems: Equipped with hardened rectangular guideways on the X/Y/Z axes, offering high load capacity and low friction. This reduces “backlash” in motion, critical for multi-axis contouring.

Spindle Stability: The spindle (10,000 RPM optional) is mounted on a rigid column, aligned vertically with the workpiece table to minimize axial runout.

Visual tip: Add a slow-motion video or animation of a test cut (e.g., a complex gear housing), overlaying “Tolerance Check Points” to demonstrate dimensional consistency.

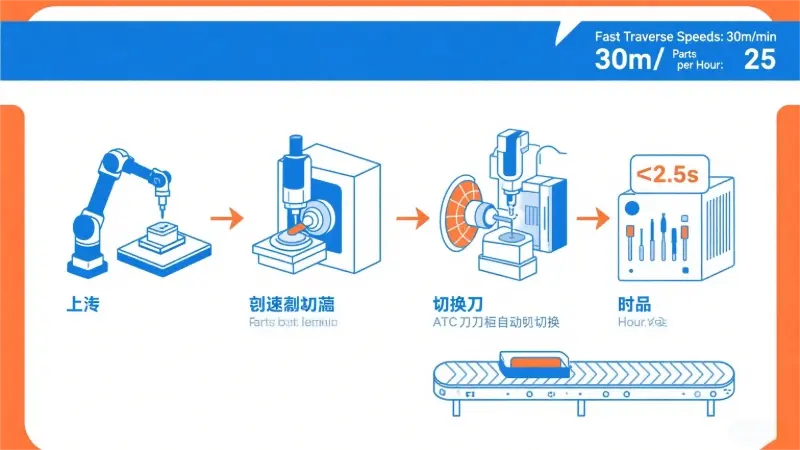

High Efficiency for Batch Production

The HMC630A balances precision with productivity, ideal for mass-producing large or complex parts (e.g., engine blocks, hydraulic valves):

Fast Traverse Speeds: X/Y/Z axes rapid traverse up to 30m/min, reducing non-cutting time between operations.

Automatic Tool Changer (ATC): A 24/30-tool magazine with a tool change time of ≤2.5 seconds minimizes downtime, keeping spindle utilization high.

Visual tip: Include a time-lapse video of a full production cycle: loading → cutting → tool change → unloading, with metrics like “Parts per Hour” displayed.

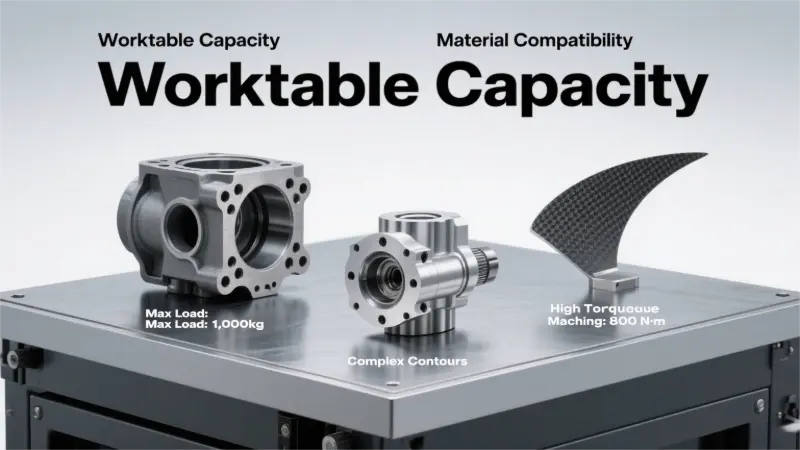

Versatility in Part Sizing & Material

Thanks to its robust structure, the HMC630A handles a wide range of workpieces:

Worktable Capacity: 630×630mm table with a maximum load of 1,000kg, accommodating large/heavy parts.

Material Compatibility: Efficiently machines metals (steel, aluminum, titanium) and composites, supported by powerful spindle torque (up to 800 N·m).

Visual tip: Showcase a gallery of machined parts with captions on material type and complexity.

Durability & Low Maintenance

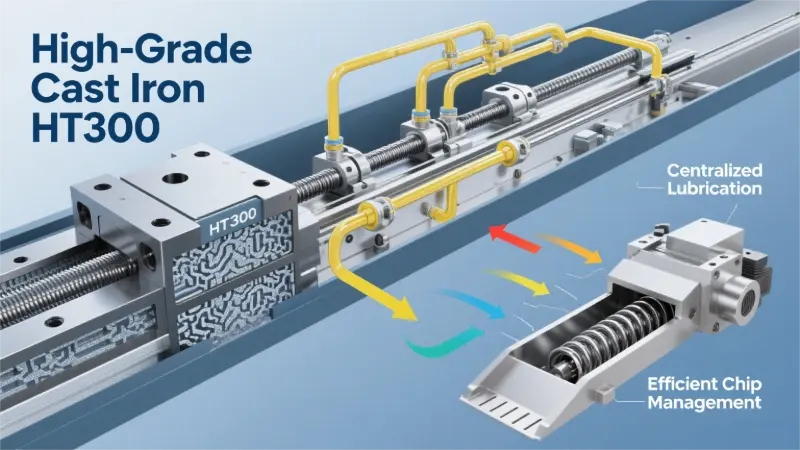

The inverted T-structure’s heavy-duty build (high-grade cast iron HT300 bed) resists wear and deformation over long-term use. Key maintenance-friendly features:

Centralized Lubrication: Automatic lubrication system for guides and screws, extending component life.