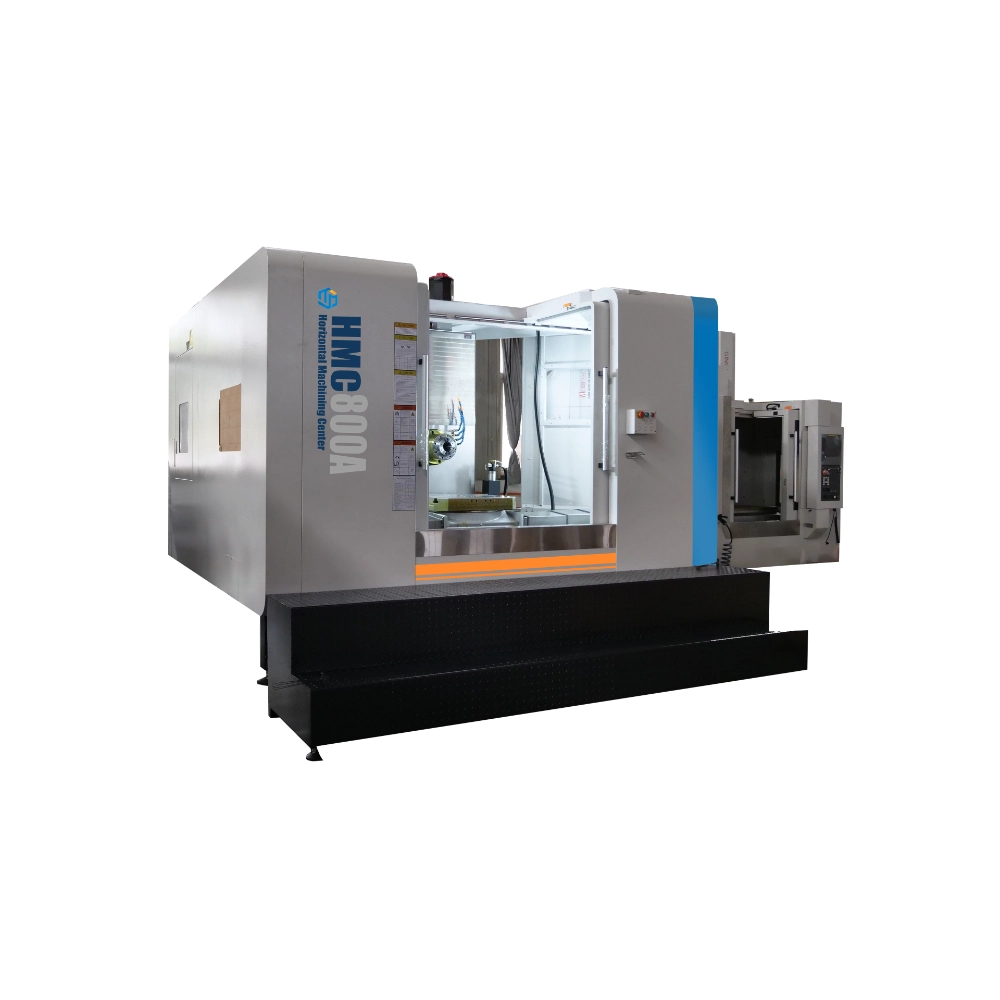

Engineered for power, stability, and productivity in large-scale machining, the HMC800A delivers exceptional performance with its advanced box-in-box structure and robust spindle design. Built to handle complex heavy-duty operations, it ensures accuracy, reliability, and long-term efficiency for manufacturers.

| Specification | HMC800A |

| Worktable | |

| Worktable size (W×L) | 800×800mm |

| Workpiece clamping type | 24×M16 |

| Changing time of worktables | / |

| Rotary diameter of workpiece | 1750mm |

| Travel | |

| X/Y/Z axis | 1600/1000/1000mm |

| Distance from spindle center to worktable surface | 160-1160mm |

| Distance from worktable center to spindle nose | 200-1200mm |

| Spindle | |

| Spindle hole taper | BT50 |

| Spindle speed range | 6000rpm |

| Drive type (Spindle) | Belt type |

| Spindle power | 15/18.5kw |

| Feed | |

| X/Y/Z axis rapid feed speed | 24/24/24m/min |

| B axis rapid feed speed | 10m/min |

| Tool magazine | |

| Tool magazine model | Manipulator |

| Capacity | 24T |

| Max. tools weight | 15kg |

| Max. tools length | 300mm |

| Tool change time | 5.5s |

| Accuracy(National standard) | |

| Positioning accuracy (X/Y/Z) | ±0.012mm |

| Re-positioning accuracy(X/Y/Z) | ±0.008mm |

| B axis division accuracy | 12’’ |

| B axis re-division accuracy | 6’’ |

| Machine Size | |

| L×W×H | 5600x4075x3180mm |

| Machine weight | |

| Max. loading of worktable | 1200kg |

| Machine weight | 17000kg |

Revolutionize Your Machining with HMC800A Horizontal Machining Center

In the fast – paced world of modern manufacturing, precision, efficiency, and reliability are the cornerstones of success. Introducing the HMC800A Horizontal Machining Center, a technological marvel that combines cutting – edge engineering with unrivaled performance to meet the most demanding machining challenges.

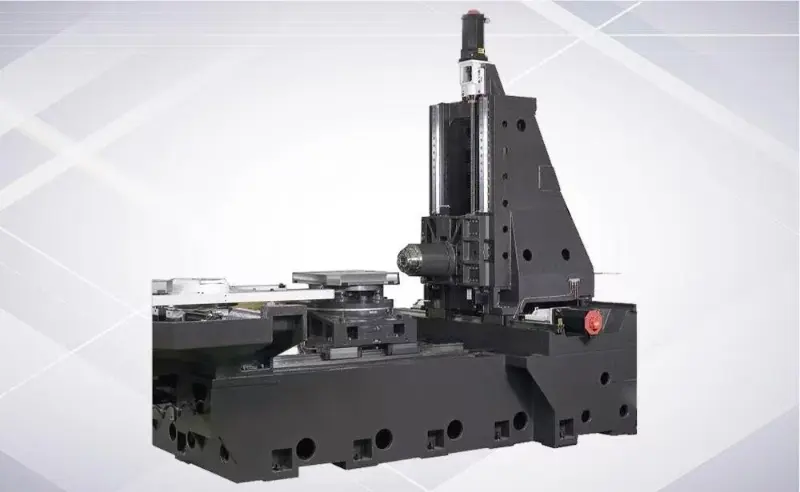

Unparalleled Structural Rigidity

The HMC800A features a robust, one – piece base and a large – span, double – wall column in a classic T – shaped structure. This design, as shown in [Insert an image here of the HMC800A’s T – shaped structure], is engineered to withstand the most intense cutting forces, ensuring maximum stability and minimal vibration during operation. The use of high – quality materials and advanced manufacturing techniques results in a machine that can endure the test of time, providing consistent performance over long production runs.

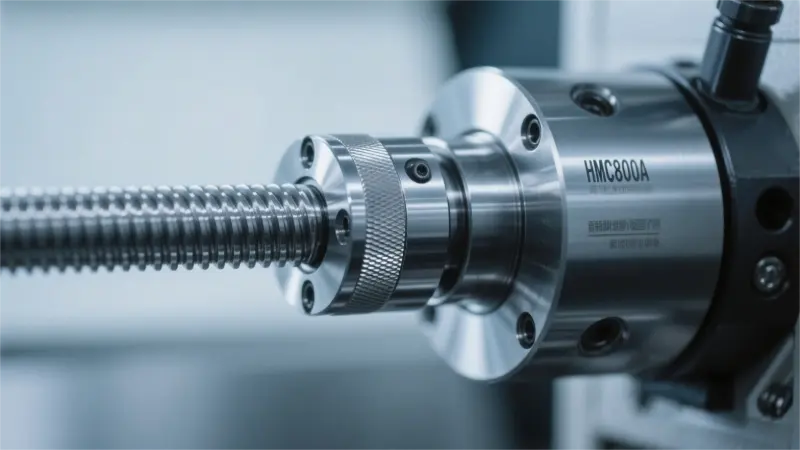

Exceptional Precision and Accuracy

Equipped with imported high – speed ball screws and a state – of – the – art, forced – cooling spindle system, the HMC800A guarantees unrivaled precision and accuracy. The spindle, which is self – weight gas – balanced, operates with minimal runout, delivering micron – level precision. Additionally, the machine’s high – resolution encoders and advanced servo control system ensure that every movement is executed with the utmost accuracy, as depicted in [Insert an image here showing the precision components]. Whether you’re working on intricate parts or large – scale components, the HMC800A can achieve the tightest tolerances, meeting the most exacting quality standards.

High – Speed, High – Torque Performance

The HMC800A is powered by a high – performance spindle that can reach speeds of up to [Insert maximum spindle speed here] RPM, providing the necessary power for high – speed machining. The spindle, combined with a powerful motor and a precision gearbox, offers exceptional torque, enabling it to handle a wide range of materials, from soft metals to hardened alloys. As demonstrated in [Insert an image here of the spindle and motor setup], this high – speed, high – torque combination allows for efficient material removal and rapid machining cycles, significantly reducing production time and costs.

Optimized Workflow with a Spacious Single Pallet

The HMC800A is equipped with a generously sized single pallet [Insert an image here of the single pallet]. This large – format pallet provides an expansive working area, capable of accommodating both large – scale workpieces and multiple smaller components simultaneously. The simplicity of the single – pallet design not only reduces the complexity of the machine but also offers enhanced accessibility for operators during workpiece setup. With fewer moving parts associated with pallet changes, the risk of mechanical failures related to such operations is minimized, ensuring consistent and reliable performance over extended usage. This setup is especially beneficial for manufacturers who deal with large, complex workpieces or those who require high – precision machining on a single part at a time, without the need for rapid pallet – to – pallet switching.

Versatile Machining Capabilities

This horizontal machining center is designed to handle a variety of machining operations, including milling, drilling, tapping, and boring. With its extensive range of tooling options and a large – capacity tool magazine, the HMC800A can quickly switch between different tools, enabling complex multi – operation machining in a single setup. Whether you’re producing automotive components, aerospace parts, or precision molds, the HMC800A has the versatility to meet your manufacturing needs.

In conclusion, the HMC800A Horizontal Machining Center is the ultimate solution for modern manufacturing. With its unrivaled structural rigidity, exceptional precision and accuracy, high – speed performance, optimized single – pallet workflow, versatile machining capabilities, intelligent control system, and industry – leading support, the HMC800A is the perfect choice for businesses looking to take their machining operations to the next level. Contact us today to learn more about the HMC800A and how it can transform your manufacturing process.