1. High perfomance cost ratio.

2.Energy consumption decrease by 20%, high stability.

3. Easy to operate, programme and maintenance.

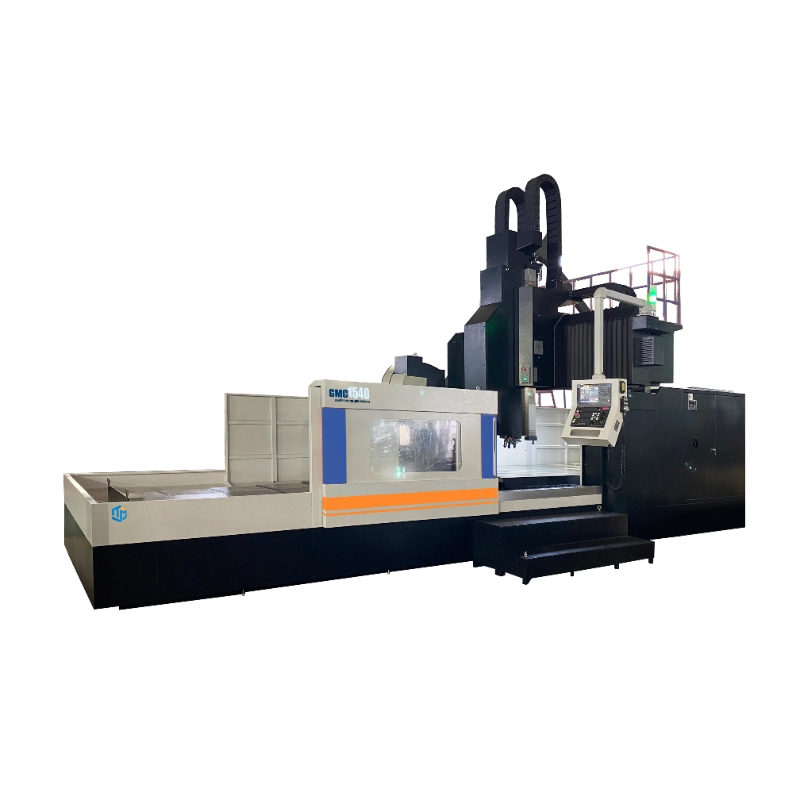

| Specification | GMC1325 |

| Worktable | |

| Worktable size (L×W) | 2500×1300mm |

| T-slots size (N×W×D) | 7-22×160mm |

| Travel | |

| X/Y/Z axis travel | 2600/1400/800mm |

| Capacity | |

| Distance from spindle nose to worktable surface | 160-960mm |

| Distance between two columns | 1400mm |

| Spindle | |

| Spindle taper | BT50 |

| Spindle power | 15/18.5kw |

| Max. spindle speed | 6000rpm |

| Spindle torque | 143N·m |

| Feed | |

| Rapid feed speed (X/Y/Z) | 10/10/10m/min |

| Ball screw (diameter+lead) | |

| X/Y/Z axis ball screw | 6316/5016/5016 |

| X/Y/Z guideway type | X/Y:roller linear guideways, Z:box guideway |

| Tool magazine | |

| Tool magazine capacity | 24T |

| Max. length of tool | 350mm |

| Tool change time (T-T) | 3s |

| Positioning accuracy (GB standard) | |

| Positioning accuracy(X/Y/Z) | 0.03mm |

| Re-positioning accuracy(X/Y/Z) | 0.018mm |

| Machine dimension | |

| L×W×H | 7800×5500×5000mm |

| Machine weight | |

| Max. loading of worktable | 6t |

| N.W | 22.5t |

Superior Machining Accuracy: Equipped with high-precision linear guides and ball screws, paired with a state-of-the-art FANUC/Siemens CNC system, achieving micron-level positioning accuracy (±0.003mm) and repeatability (±0.002mm). The rigid gantry design minimizes vibration, ensuring impeccable surface finishes (Ra ≤ 1.6μm) even for complex 3D contours.

High-Speed Productivity: A powerful 15kW spindle with speeds up to 8000rpm enables rapid material removal, while the fast feed rate (X/Y/Z axes: 24/24/18m/min) reduces cycle times by up to 30% compared to conventional machines. The large worktable (1300×2500mm) accommodates oversized workpieces, supporting one-time clamping for multi-operation processing.

Intelligent & User-Friendly: The 15-inch touchscreen HMI offers intuitive programming with built-in CAD/CAM software compatibility. Automated features like tool length measurement, spindle cooling, and chip conveyor enhance operational safety and reduce manual intervention. Remote monitoring via IoT connectivity allows real-time production tracking and predictive maintenance.

Durable & Low Maintenance: Constructed with high-grade cast iron and stress-relieved components, the machine ensures long-term stability (MTBF ≥ 5000 hours). Sealed guideways and centralized lubrication system extend service life, lowering maintenance costs by 25% annually.

Applications:

Ideal for machining large steel structures, aluminum alloys, composite materials, and precision molds. Trusted by leading manufacturers for its reliability and ability to meet tight tolerances in high-volume production.