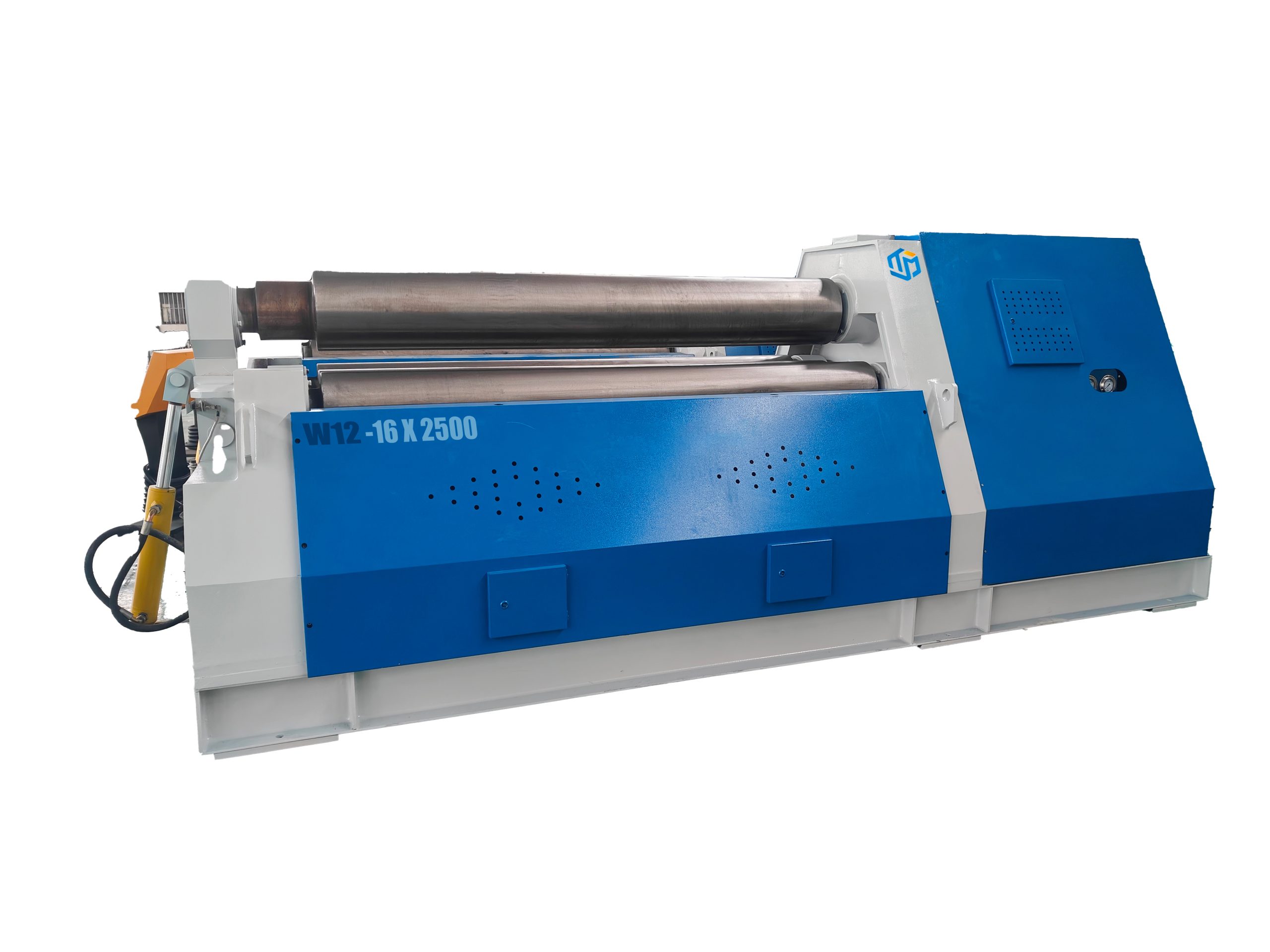

It belongs to four roller plate rolling machine, It wide used in the manufacture of pressure vessels, machinery, hydropower, construction and other industries of the barrel body pre bending, roll round, and also have a function of checking circle and leveling. The top roller driven by hydraulic motor. Through the friction between the metal plate and the top roller to drive the bottom roller and side rollers rotate. And supply the torque for bending plate. The bottom roller, side roller and drop end are all driven by hydraulic oil tank, The bottom roller move up and down, the side roller move along with an arc. The bottom roller rising to clamp the plate and the side roller title up to pre-bend the end of the plate.

| Model | W12-11×2500 |

| Max.rolingthickness | 11mm |

| Max. pre-bendingthickness | 8mm |

| Max.rollingwidth | 2000mm |

| Diameter oftop roler | 260mm |

| Diameterof bottom roller | 220mm |

| Diameter of side rolers | 180mm |

| Min.fullloadingdiameter of coiled plate | 450mm |

| Rolling speed | 4.5m/min |

| Motor power | 7.5kw |

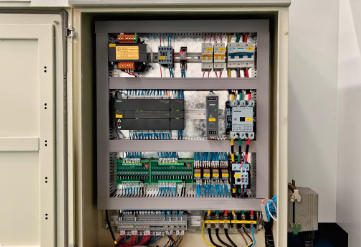

CNC System

The plate rolling machine features an advanced CNC control system, allowing precise and programmable roller movements. It enables accurate bending, easy operation, and consistent high-quality results for various plate shapes and thicknesses.

42CrMo Heat Treated Steel

The upper roller is made of 42CrMo heat-treated steel, with a drum shape that works together with carrier rollers to achieve smooth and continuous bending of plates in different thicknesses. The bottom roller and side rollers are powered by a hydraulic oil tank, ensuring strong force, stable movement, and accurate forming.

Hydraulic Motor

The plate rolling machine is equipped with a powerful hydraulic motor, providing stable torque and smooth operation. It ensures reliable performance, precise rolling, and long service life with low maintenance needs.

Control Cabinet

The plate rolling machine is equipped with an independent control cabinet, featuring a user-friendly interface and reliable electrical components. It allows easy operation, precise parameter adjustment, and ensures safe and stable machine performance.

Unloading Device

The plate rolling machine is equipped with an efficient unloading device, allowing smooth and safe removal of finished plates. It reduces manual labor, improves workflow, and ensures stable handling of heavy or large metal plates.