Esta máquina é adequada para fresamento, mandrilamento, furação, rosqueamento, etc. Usinagem de metais ferrosos e não ferrosos, pode concluir vários processos com apenas uma instalação da peça de trabalho, garantindo a qualidade dos produtos e a eficiência da produção.

| Especificação | GMC1016 |

| Mesa de trabalho | |

| Tamanho da mesa de trabalho (C×L) | 1600×1000 mm |

| Tamanho das ranhuras em T (N×L×P) | 7-22x125 mm |

| Viagem | |

| Deslocamento do eixo X/Y/Z | 1650/1100/600 mm |

| Capacidade | |

| Distância da ponta do fuso à superfície da mesa de trabalho | 160-760 mm |

| Distância entre duas colunas | 1250 mm |

| Fuso | |

| Cone do fuso | BT50 |

| Potência do fuso | 15/18,5 kW |

| Velocidade máxima do fuso | 7000 rpm |

| Torque do fuso | 143N·m |

| Alimentar | |

| Velocidade de avanço rápido (X/Y/Z) | 20/20/12 m/minuto |

| Fuso de esferas (diâmetro + avanço) | |

| Fuso de esferas do eixo X/Y/Z | 6320/5012/5020 |

| Tipo de guia X/Y/Z | X/Y: guias lineares de rolos, Z: guia de caixa |

| Revista de ferramentas | |

| Capacidade do carregador de ferramentas | 24T |

| Comprimento máximo da ferramenta | 350 mm |

| Tempo de troca de ferramenta (TT) | 3s |

| Precisão de posicionamento (padrão GB) | |

| Precisão de posicionamento (X/Y/Z) | 0,03 mm |

| Precisão de reposicionamento (X/Y/Z) | 0,018 mm |

| Dimensão da máquina | |

| C×L×A | 6000×4000×3900 mm |

| Peso da máquina | |

| Carga máxima da mesa de trabalho | 3,5t |

| NO | 18t |

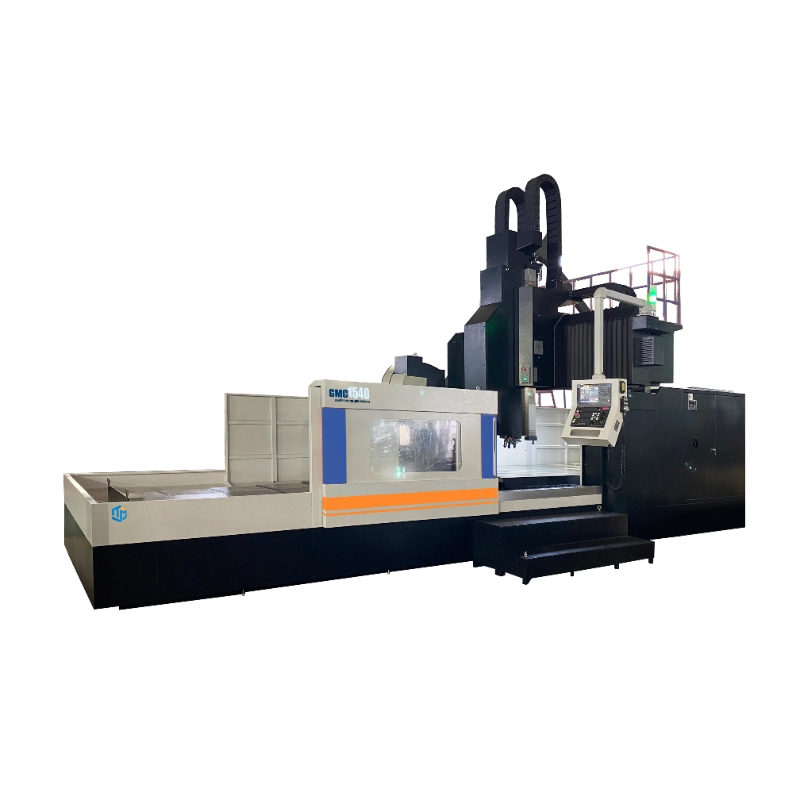

O centro de usinagem CNC tipo pórtico GMC1016 apresenta parâmetros de desempenho robustos, que estabelecem uma base sólida para sua usinagem eficiente. Sua ampla mesa de trabalho atende às necessidades de usinagem de peças grandes, enquanto sua forte capacidade de carga permite um suporte estável para peças pesadas durante a usinagem.

Em termos de precisão de usinagem, a GMC1016 se destaca. Ela adota trilhos-guia e fusos de avanço de alta precisão e, quando combinada com um sistema CNC avançado, atinge precisão de usinagem de nível micrométrico, garantindo que as peças usinadas apresentem dimensões precisas e um alto acabamento superficial.

A alta eficiência de usinagem é outra vantagem fundamental da GMC1016. Seu fuso de alta velocidade e taxas de avanço rápidas podem reduzir significativamente o tempo de usinagem, aumentar a eficiência da produção e, assim, trazer maiores benefícios econômicos para as empresas.

A GMC1016 também se destaca pela conveniência operacional e funcionalidade inteligente. Sua interface de usuário é simples e intuitiva, enquanto seu sistema CNC é potente, permitindo o processamento automatizado, reduzindo a intervenção manual, diminuindo a dificuldade operacional e aumentando a estabilidade e a confiabilidade da produção.