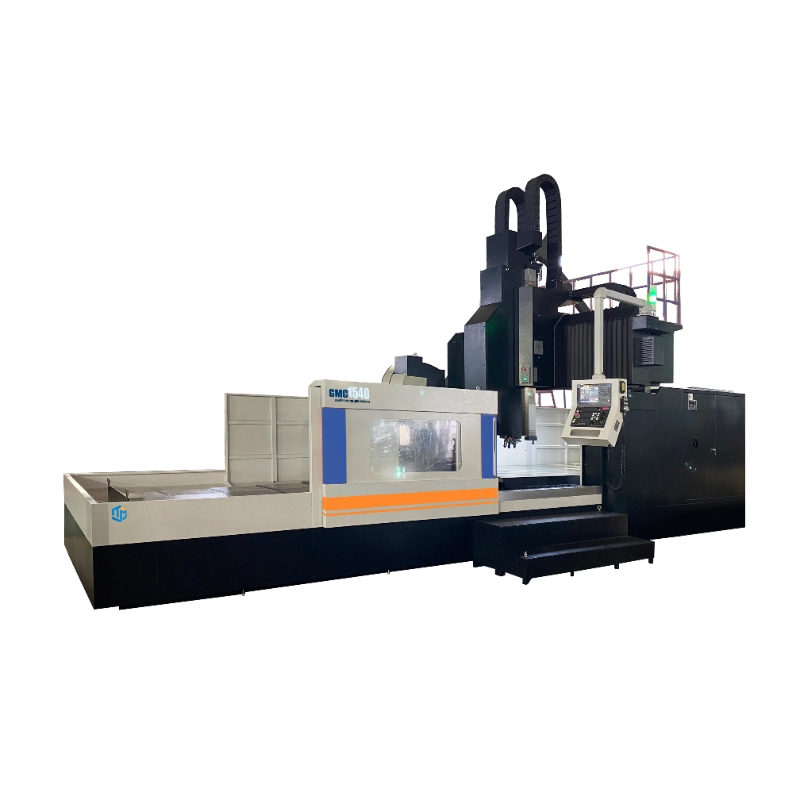

Esta máquina é adequada para fresamento, mandrilamento, fresamento, rosqueamento, etc. Usinagem de metais ferrosos e não ferrosos, pode concluir vários processos com apenas uma instalação da peça de trabalho, garantindo a qualidade dos produtos e a eficiência da produção.

| Especificação | GMC1540 |

| Mesa de trabalho | |

| Tamanho da mesa de trabalho (C×L) | 4000×1500 mm |

| Tamanho das ranhuras em T (N×L×P) | 9-22×160 mm |

| Viagem | |

| Deslocamento do eixo X/Y/Z | 4100/1650/800 mm |

| Capacidade | |

| Distância da ponta do fuso à superfície da mesa de trabalho | 160-960 mm |

| Distância entre duas colunas | 1650 mm |

| Fuso | |

| Cone do fuso | BT50 |

| Potência do fuso | 15/18,5 kW |

| Velocidade máxima do fuso | 6000 rpm |

| Torque do fuso | 143N·m |

| Alimentar | |

| Velocidade de avanço rápido (X/Y/Z) | 10/10/10m/min |

| Fuso de esferas (diâmetro + avanço) | |

| Fuso de esferas do eixo X/Y/Z | 8020/5016/5016 |

| Tipo de guia X/Y/Z | X/Y: guias lineares de rolos, Z: guia de caixa |

| Revista de ferramentas | |

| Capacidade do carregador de ferramentas | 24T |

| Comprimento máximo da ferramenta | 350 mm |

| Tempo de troca de ferramenta (TT) | 3s |

| Precisão de posicionamento (padrão GB) | |

| Precisão de posicionamento (X/Y/Z) | 0,03 mm |

| Precisão de reposicionamento (X/Y/Z) | 0,018 mm |

| Dimensão da máquina | |

| C×L×A | 10800×5800×5000mm |

| Peso da máquina | |

| Carga máxima da mesa de trabalho | 8t |

| NO | 28t |

Capacidade de Usinagem Ampliada: Com uma mesa de trabalho robusta (1500 x 4000 mm) e um curso vertical de 800 mm no eixo Z, a GMC1540 processa componentes extragrandes com facilidade. A estrutura reforçada do pórtico de coluna dupla, fabricada em ferro fundido de alta resistência, garante deflexão mínima sob cargas pesadas, mantendo a estabilidade durante cortes em alta velocidade.

Desempenho de alta potência: Equipada com um motor de fuso de 22 kW (30 kW opcional) e velocidades de até 6.000 rpm, usina com eficiência materiais resistentes como aço-liga e titânio. O sistema de avanço servoacionado atinge velocidades de avanço rápidas (X/Y/Z: 20/20/15 m/min), reduzindo o tempo sem corte e aumentando a produtividade em 251 TP3T para produção em lote.

Controle de Precisão Avançado: Com um sistema CNC Heidenhain/FANUC com capacidade de interpolação de 5 eixos, a máquina oferece precisão de posicionamento de ±0,005 mm e repetibilidade de ±0,003 mm. O ajustador de ferramentas a laser e a sonda de peça integrados permitem calibração automatizada, eliminando erros manuais e garantindo a qualidade consistente das peças.

Integração Inteligente de Fábrica: A interface homem-máquina (IHM) com tela sensível ao toque industrial de 19 polegadas suporta transferência de dados CAD/CAM e diagnóstico remoto sem interrupções via protocolo OPC UA. A remoção automática de cavacos, a reciclagem do líquido de arrefecimento e o modo de economia de energia (energia em espera ≤ 5 kW) otimizam a eficiência da oficina e reduzem os custos operacionais.

Aplicações:

Perfeito para usinagem de peças estruturais de grande formato, componentes de turbinas, seções para construção naval e matrizes de precisão. Sua versatilidade o torna um alicerce para fabricantes que exigem tamanho e precisão na produção em larga escala.