1. Alta relação custo-desempenho.

2. Diminuição do consumo de energia em 20%, alta estabilidade.

3. Fácil de operar, programar e manter.

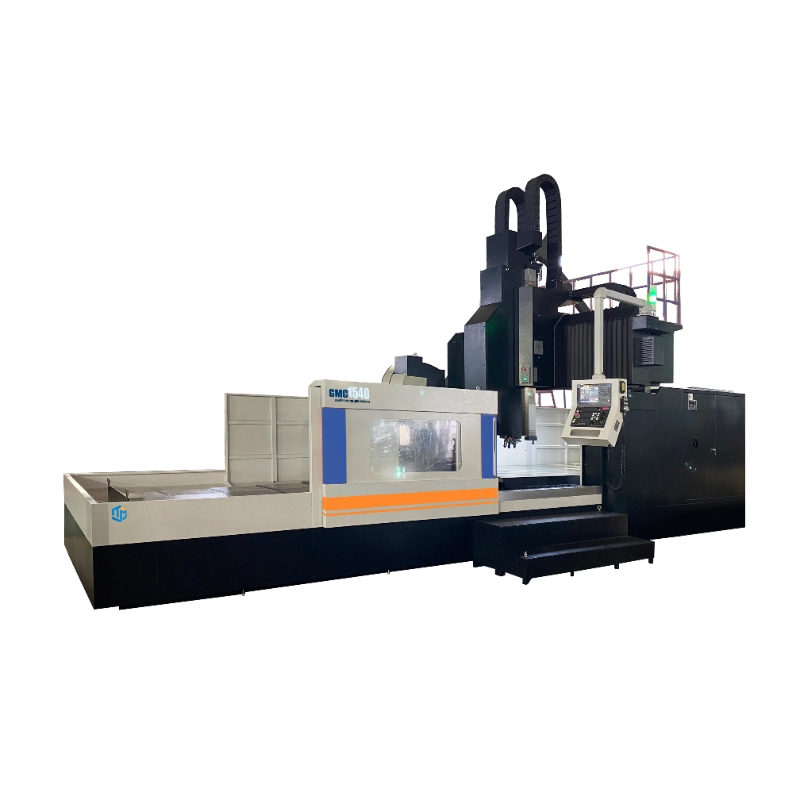

| Especificação | GMC1325 |

| Mesa de trabalho | |

| Tamanho da mesa de trabalho (C×L) | 2500×1300 mm |

| Tamanho das ranhuras em T (N×L×P) | 7-22×160 mm |

| Viagem | |

| Deslocamento do eixo X/Y/Z | 2600/1400/800 mm |

| Capacidade | |

| Distância da ponta do fuso à superfície da mesa de trabalho | 160-960 mm |

| Distância entre duas colunas | 1400 mm |

| Fuso | |

| Cone do fuso | BT50 |

| Potência do fuso | 15/18,5 kW |

| Velocidade máxima do fuso | 6000 rpm |

| Torque do fuso | 143N·m |

| Alimentar | |

| Velocidade de avanço rápido (X/Y/Z) | 10/10/10m/min |

| Fuso de esferas (diâmetro + avanço) | |

| Fuso de esferas do eixo X/Y/Z | 6316/5016/5016 |

| Tipo de guia X/Y/Z | X/Y: guias lineares de rolos, Z: guia de caixa |

| Revista de ferramentas | |

| Capacidade do carregador de ferramentas | 24T |

| Comprimento máximo da ferramenta | 350 mm |

| Tempo de troca de ferramenta (TT) | 3s |

| Precisão de posicionamento (padrão GB) | |

| Precisão de posicionamento (X/Y/Z) | 0,03 mm |

| Precisão de reposicionamento (X/Y/Z) | 0,018 mm |

| Dimensão da máquina | |

| C×L×A | 7800×5500×5000 mm |

| Peso da máquina | |

| Carga máxima da mesa de trabalho | 6t |

| NO | 22,5t |

Precisão de usinagem superior: Equipado com guias lineares e fusos de esferas de alta precisão, combinados com um sistema CNC FANUC/Siemens de última geração, alcança precisão de posicionamento em nível de micrômetro (±0,003 mm) e repetibilidade (±0,002 mm). O design rígido do pórtico minimiza a vibração, garantindo acabamentos superficiais impecáveis (Ra ≤ 1,6 μm), mesmo para contornos 3D complexos.

Produtividade em Alta Velocidade: Um potente fuso de 15 kW com velocidades de até 8000 rpm permite a rápida remoção do material, enquanto a alta taxa de avanço (eixos X/Y/Z: 24/24/18 m/min) reduz os tempos de ciclo em até 301 TP3T em comparação com máquinas convencionais. A ampla mesa de trabalho (1300 × 2500 mm) acomoda peças de grandes dimensões, permitindo fixação única para processamento multi-operação.

Inteligente e fácil de usar: A interface homem-máquina (IHM) touchscreen de 15 polegadas oferece programação intuitiva com compatibilidade com software CAD/CAM integrado. Recursos automatizados, como medição do comprimento da ferramenta, resfriamento do fuso e transportador de cavacos, aumentam a segurança operacional e reduzem a intervenção manual. O monitoramento remoto via conectividade IoT permite o acompanhamento da produção em tempo real e a manutenção preditiva.

Durável e de baixa manutenção: Construída com ferro fundido de alta qualidade e componentes com alívio de tensões, a máquina garante estabilidade a longo prazo (MTBF ≥ 5000 horas). Guias seladas e sistema de lubrificação centralizada prolongam a vida útil, reduzindo os custos de manutenção em 25% anualmente.

Aplicações:

Ideal para usinagem de grandes estruturas de aço, ligas de alumínio, materiais compósitos e moldes de precisão. Utilizado pelos principais fabricantes por sua confiabilidade e capacidade de atender a tolerâncias rigorosas em produções de alto volume.