Para que servem as máquinas-ferramenta HMC?

Data de lançamento: 14/11/2025

Índice

Na manufatura moderna, as máquinas-ferramenta são cada vez mais utilizadas. Diferentes tipos de máquinas-ferramenta possuem funções e características distintas. Entre elas, as máquinas-ferramenta HMC, como importantes equipamentos de usinagem, são amplamente utilizadas em diversos setores devido à sua alta eficiência e capacidade de usinagem de precisão. Mas, afinal, para que servem as máquinas-ferramenta HMC? A Topmade apresentará uma introdução detalhada às principais funções das máquinas-ferramenta HMC, com foco na importância dos centros de usinagem horizontais dentro da categoria de máquinas-ferramenta HMC.

O que é uma máquina-ferramenta HMC?

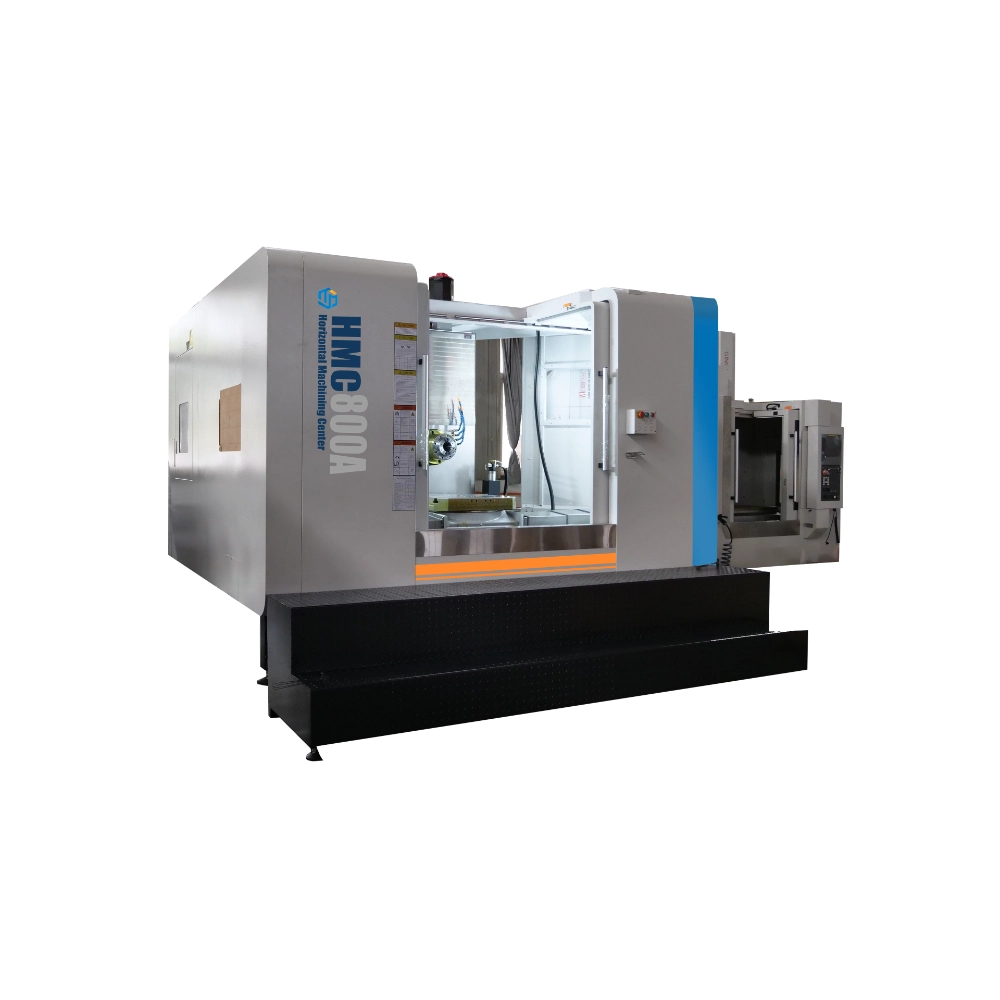

Uma máquina-ferramenta HMC, ou centro de usinagem horizontalO centro de usinagem horizontal é uma máquina-ferramenta de alta eficiência que integra múltiplos métodos de usinagem, como fresamento, furação e rosqueamento. Sua característica mais marcante é a mesa de trabalho geralmente disposta horizontalmente, o que a torna adequada para usinar peças de grandes dimensões. Comparado aos centros de usinagem verticais tradicionais, o centro de usinagem horizontal oferece maior estabilidade, especialmente na usinagem de peças grandes e complexas, garantindo precisão e eficiência.

Principais aplicações das máquinas-ferramenta HMC

As máquinas-ferramenta HMC têm uma ampla gama de aplicações, abrangendo quase todos os campos que exigem usinagem de alta precisão. Aqui estão alguns cenários de aplicação comuns:

Fabricação de automóveis: Na indústria automotiva, as máquinas-ferramenta HMC são utilizadas para processar peças complexas, como componentes de motores e peças estruturais da carroceria. A estabilidade e a alta precisão dos centros de usinagem horizontais desempenham um papel crucial na produção dessas peças exigentes.

Aeroespacial: As máquinas-ferramenta HMC são amplamente utilizadas na área aeroespacial, especialmente para usinagem de componentes de alta precisão, como motores de aeronaves e peças de espaçonaves. Elas podem realizar usinagem complexa e multifacetada, reduzindo o manuseio e o reposicionamento das peças e melhorando a eficiência da usinagem.

Fabricação de moldes: Para a indústria de fabricação de moldes, os centros de usinagem horizontais são equipamentos indispensáveis. Eles podem realizar usinagem em múltiplos processos e garantir a precisão e a qualidade da superfície dos moldes durante o processo de usinagem.

Usinagem de Precisão: Máquinas-ferramenta HMC São particularmente adequadas para usinagem de peças mecânicas de alta precisão, como eixos e engrenagens de precisão. Devido à sua grande capacidade de usinagem, garantem alta precisão e alta qualidade das peças.

Vantagens dos Centros de Usinagem Horizontais

Como um tipo de máquina-ferramenta HMC, os centros de usinagem horizontais apresentam vantagens significativas em relação aos centros de usinagem verticais. Primeiro, o layout horizontal de um centro de usinagem horizontal proporciona uma fixação mais estável da peça, tornando-o particularmente adequado para usinagem de peças pesadas. Segundo, os centros de usinagem horizontais oferecem maior eficiência de corte, especialmente na usinagem de múltiplas faces de peças grandes. Eles podem executar várias etapas de usinagem simultaneamente, reduzindo a necessidade de virar a peça e o tempo de usinagem, melhorando assim a eficiência da produção.

Além disso, a posição mais baixa da mesa de trabalho em um centro de usinagem horizontal permite aos operadores uma fixação e um ajuste mais fáceis, melhorando a eficiência do trabalho e a segurança operacional. Com o uso de trocadores automáticos de ferramentas, os centros de usinagem horizontais também podem alcançar uma produção automatizada altamente eficiente, reduzindo a intervenção manual.

Manutenção e conservação de máquinas-ferramenta HMC

Embora as máquinas-ferramenta HMC possuam alta capacidade de usinagem, a manutenção e os cuidados regulares são essenciais para garantir uma operação estável a longo prazo. Os operadores devem verificar regularmente os sistemas de lubrificação, refrigeração e elétrico da máquina-ferramenta para garantir que todos os componentes estejam funcionando corretamente. Em particular, a mesa de trabalho e o fuso do centro de usinagem horizontal devem ser mantidos limpos para evitar o acúmulo de fluido de corte e cavacos metálicos, o que pode levar a uma diminuição da precisão da usinagem.

Resumo

Em conclusão, as máquinas-ferramenta HMC, especialmente os centros de usinagem horizontais, são equipamentos indispensáveis e importantes na manufatura moderna. Elas podem executar com eficiência e precisão as tarefas de usinagem de diversas peças complexas e são amplamente utilizadas nas indústrias automotiva, aeroespacial, de moldes e de máquinas de precisão. No futuro, com os avanços tecnológicos contínuos, as capacidades de usinagem e os níveis de automação das máquinas-ferramenta HMC serão ainda mais aprimorados, tornando-as ferramentas de produção insubstituíveis e essenciais em muitos outros setores.

Se você precisa comprar ou usar máquinas-ferramenta HMC, escolher uma de alto desempenho, centro de usinagem horizontal confiável Será um passo importante para melhorar a eficiência da sua produção e garantir a precisão da usinagem.