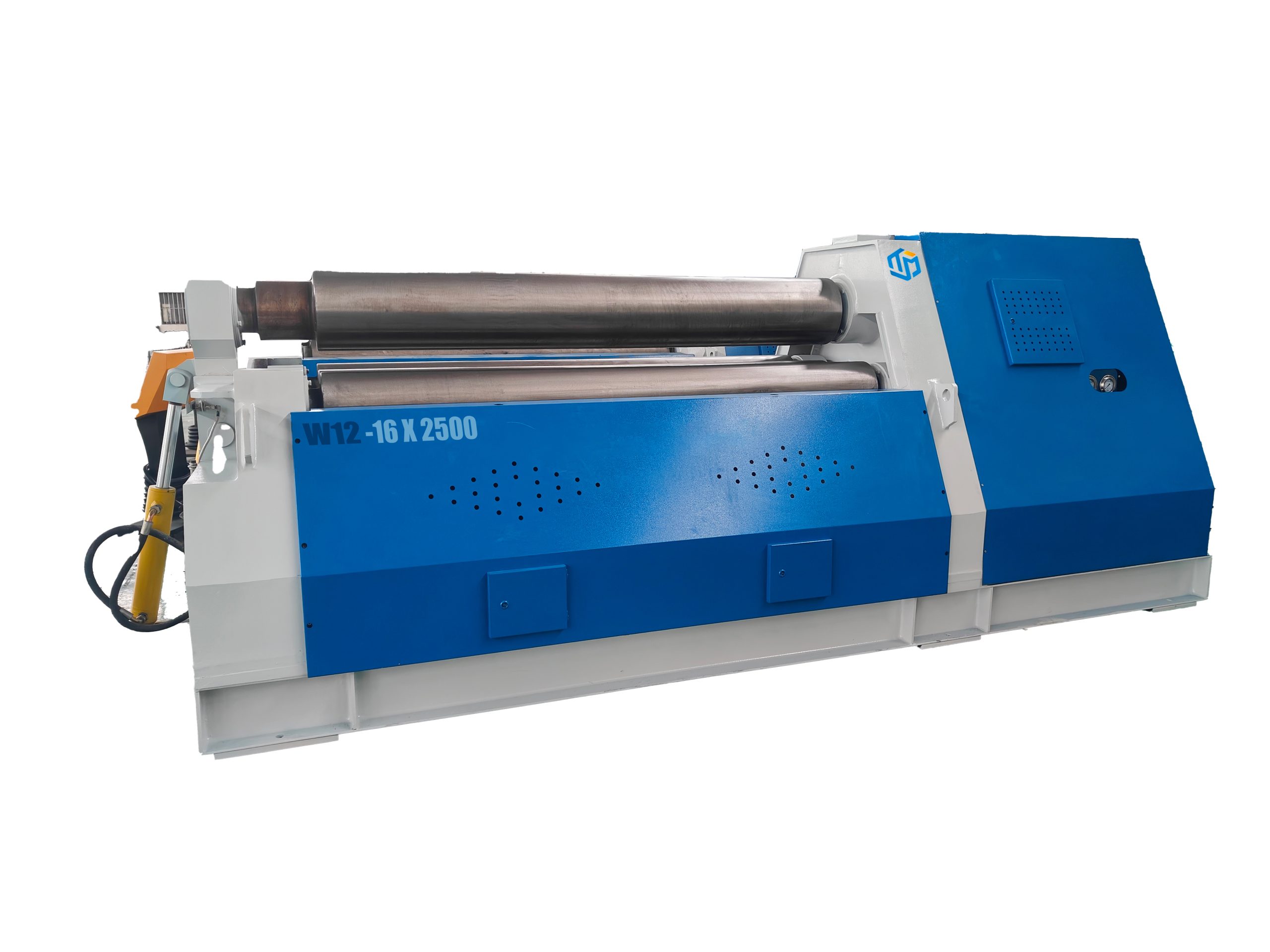

This is symmetric bending machine. The cylinder rolling is completed by the upper roller which pressing to the lower one and the mutual rolling. The machine consists of two parts, the operation part and the transmission part which are welded at the whole bottom pallet. The operation part consists of left and right bearing housing, one upper roller, two lower rollers, lifting gears and some accessories. The lower roller is the main one, upper roller can be adjusted at the height. The transmission part consists with the main motor, speed-reducing motor and other accessories. The lower roller is driven by the main motor through the main reduce. The main reductor output shaft transmits to the two lower rollers through a group of gear wheel. The roller driving direction is switched by the main motor. The elevation movement of the upper roller is realized by the auxiliary motor through the auxiliary reductor, which drives worm and worm wheel under the left and right roller bearing to move automatically, makes the steel wire nut which is fixed on the worm wheel rotating, and completed by up and down movement of ball bearing screws accordingly. The offloading device is used after the round cylinder have been finished. Before leaving the left bearing seat, raises the upper roller to standard height, and make the upper roller stop with balance pull rod at the bottom of upper roller. Then draw out pin shaft on the tilting bearing seat, overturn the tilting bearing seat, then the coiled product can emerge from one end of the upper roller. The main components are: three 45 steel forged rollers, HRC3545, support frame is welded, process after being welded, the lower pallet is a welded part. Ball bearing screw and worm gear are 45 steel forged parts. Electrical parts is adopted famous apparatus, steady performance, durable, safe and reliable, operates conveniently.

| Model | W11-12X2000 |

| Pressure on the upper roller | 65t |

| Diameter of upper roller | 250mm |

| Diameter of lower roller | 145mm |

| Central distance | 200mm |

| Driving power | 5.5kw |

| Hydraulic power | 4kw |

| Moving power | 0.75kw |

Roller

The top roller do the movement of elevation in the central position of the two botton rolls.

It is tranmitted by screw nut and worm gear two bottom rolls are main drive rolls.Safety

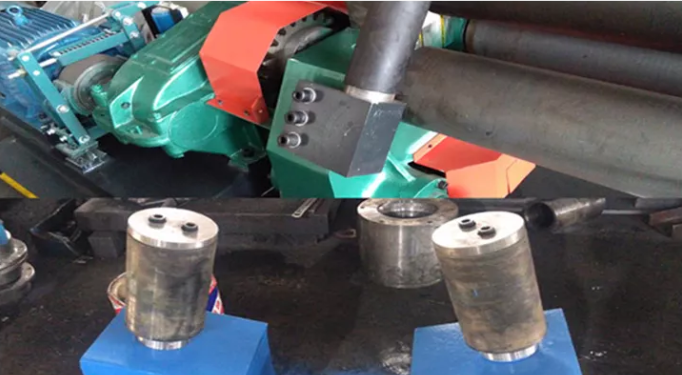

Release device

The offloading device is used after the round cylinder have been finished. Before leaving the left bearing sear, raised the upper roller to standard height, and make the upper roller stop with balance pull rod at the bottom of upper roller.

The draw out pin shaft on the tilting bearing sear, overturn the tilting bearing seat, then the coiled product can emerge from one end of the upper roller.

one bending device

Making the cone shape

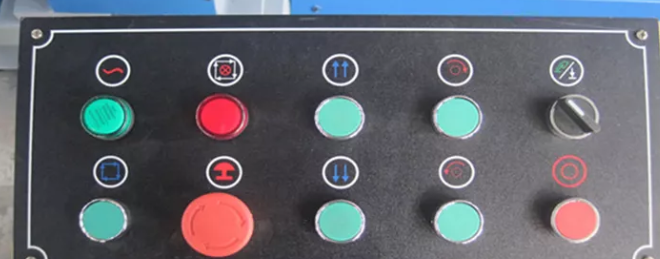

Movable control panel

Steel sheet rolling machine, hydraulic plate rolling machine, and hydraulic sheet plate bending machine for sale are provided by BLMA – plate rolling machine manufacturers.