Three Reasons to Choose a CNC Vertical Machining Center

Release time: 2025-09-27

Table of Contents

In modern manufacturing, CNC vertical machining centers (CNC VMCs) have become a core piece of equipment in many companies’ production lines due to their efficiency, precision, and flexibility. Whether engaged in large-scale batch production or customized customization, small and medium-sized businesses can benefit from using CNC VMCs. Topmade will explain three reasons to choose a CNC VMC and help you understand its importance in production.

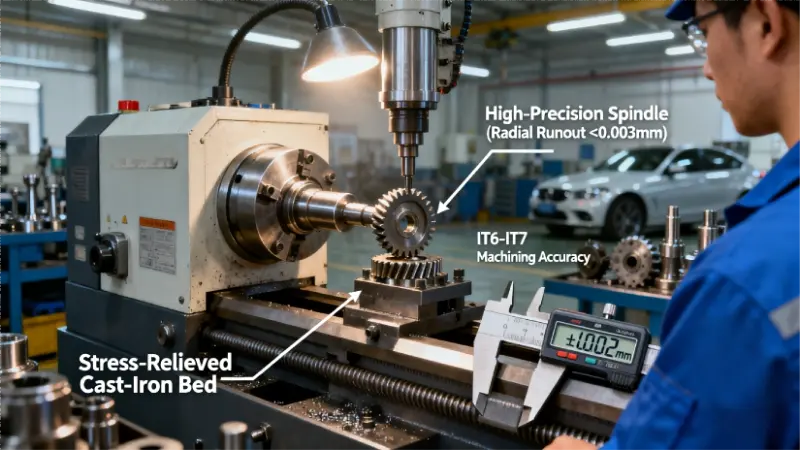

Improve Machining Precision and Ensure Product Quality

CNC vertical machining centers utilize computer numerical control (CNC) technology, enabling precise control of each machining step, minimizing errors during the machining process. Compared to traditional manual operations, CNC systems ensure consistent high precision across multiple machining passes for each part, thereby improving product quality and consistency. CNC VMCs are particularly important in industries requiring high-precision machining, such as automotive, aerospace, and precision machinery. Their precision can reach micron levels, significantly improving production efficiency and reducing human error.

Improve Production Efficiency and Reduce Delivery Cycles

CNC vertical machining centers feature high automation and high production speeds, enabling 24-hour operation. Equipped with a variety of automated features, such as automatic tool changing and automatic tool setting, these machines can complete complex machining tasks in the shortest possible time. Through programming and automated CNC system control, production lines can achieve efficient mass production, significantly improving production efficiency and effectively shortening delivery cycles.

Furthermore, CNC vertical machining centers offer exceptional stability and repeatability, eliminating common manual errors and reducing downtime caused by equipment failure or operator mishandling. These features make them particularly suitable for industries requiring rapid response to customer needs and orders, particularly in electronics manufacturing and medical devices.

Flexible Adaptation to Diverse Machining Needs Enhances Business Competitiveness

CNC vertical machining centers can not only process a variety of materials, including metals and plastics, but also offer significant processing flexibility. They support complex part machining operations, such as drilling, milling, tapping, scraping, and internal and external machining, meeting the customized needs of diverse customers. Whether operating a single piece in small batches or large-scale production, CNC vertical machining centers can easily handle both production diversity and flexibility.

Through efficient production capabilities and flexible machining methods, CNC vertical machining centers can help businesses quickly adapt to market changes and enhance their competitiveness. For small and medium-sized enterprises, investing in a CNC vertical machining center not only improves production efficiency and quality, but also reduces unit production costs, thereby gaining a competitive advantage in the fierce market.

Conclusion

CNC vertical machining centers are undoubtedly indispensable production equipment in modern manufacturing, providing businesses with high-precision, high-efficiency, and flexible machining capabilities. Whether improving product quality, increasing production efficiency, or adapting to diverse machining needs, CNC vertical machining centers offer significant advantages. Therefore, choosing a high-performance CNC vertical machining center not only helps businesses optimize their production processes but also enhances their market competitiveness. It is a crucial investment that every manufacturing company cannot ignore.