The XL6436CL universal milling machine is engineered to redefine flexibility and reliability in precision machining, making it a standout choice for small-to-medium enterprises, workshops, and industrial production lines. Its core strengths address diverse machining needs while ensuring consistent performance.

| specification | XL6436CL |

| Worktable | \ |

| Table size(LxW) | 1600×360mm |

| Tslot(NxWxD | 3-18/80mm |

| Travel | \ |

| Table tavel (X/Y/Z) | 1300/3201450mm |

| Tablefeed(X/Y/Z) | \ |

| Swivel Table | ±45°0ptional |

| Ram travel | 600mm |

| Spindle | \ |

| Spindle taper | 7.24 ISO50(HV) |

| Distance between spindle nose and table surface | 190-590mm |

| Spindle sped(12 steps) | \ |

| Main motor power | 4kw(V),5.5kw(H) |

| Horizontal | \ |

| Distance between hoizontal nose and table suface | 175625mm |

| Distance between horizontal nose and am surface | 200mm |

| Machine weight | \ |

| Max loading capacity | 350kg |

| N.w | 2800kg |

| 3phase ACfeeding servo motor torque | 10N.m |

| Overall size | \ |

| L×W×H | 2520×2100×2000mm |

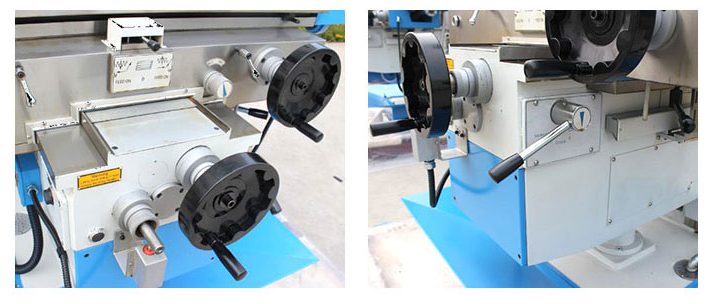

Strong Versatility: Handles horizontal/vertical milling, slotting, gear cutting; works with steel, aluminum, plastics.

Stable & Accurate: Thick cast iron bed reduces vibration; ensures consistent cuts and longer tool life.

Easy to Operate: Intuitive control panel + ergonomic handwheels; suitable for all skill levels, cuts setup time.

Flexible Speed/Feed: 60-1800 RPM spindle; adapts to tough metals or light materials.

Durable & Compact: Sealed bearings lower maintenance; space-saving design fits small workshops