Why Must Large Workpieces Choose a Gantry Machining Center?

Release time: 2026-01-28

Table of Contents

In the field of large workpiece machining, equipment selection directly affects processing efficiency, machining accuracy, and long-term operating costs. Compared with traditional vertical machining centers, more and more manufacturing enterprises are choosing gantry machining centers for applications such as heavy structural parts, large molds, and machine tool beds. So what makes gantry machining centers the preferred choice? This article analyzes the three core differences to help you make a rational equipment decision.

Structural Rigidity Determines the Upper Limit of Large-Part Machining

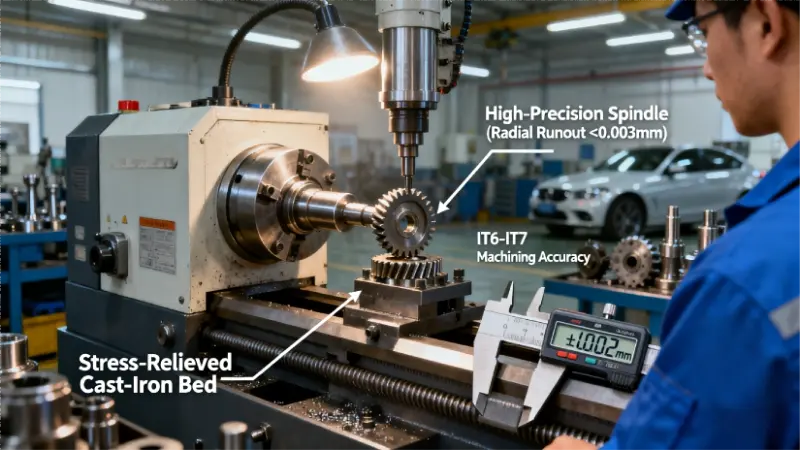

Vertical machining centers use a single-column structure and are more suitable for small and medium-sized parts. In contrast, gantry machining centers feature a dual-column and crossbeam structure, providing superior rigidity and more balanced force distribution. When machining large, long, or heavy workpieces, gantry machining centers effectively reduce vibration and deformation, ensuring stable and high machining accuracy. This is why industries such as mold manufacturing, rail transit, and construction machinery widely adopt high-rigidity gantry machining centers.

Machining Range and Load Capacity Show Significant Differences

In terms of table size and load capacity, vertical machining centers are clearly limited. Large gantry machining centers allow multi-surface machining with a single clamping, avoiding repeated setups and minimizing positioning errors. For enterprises engaged in mass production or oversized workpiece machining, choosing a heavy-duty gantry machining center not only improves efficiency but also significantly reduces labor and time costs.

Machining Efficiency and Long-Term Investment Costs

Although gantry machining centers require a higher initial investment, their high efficiency, strong stability, and low rework rate greatly reduce per-part machining costs in the long run. For B2B manufacturing enterprises, a cost-effective gantry machining center helps build stable production capacity, improve delivery performance, and enhance overall market competitiveness.

Conclusion

In summary, when facing large workpiece machining with high precision and stability requirements, gantry machining centers offer clear advantages in structure, load capacity, and efficiency. Enterprises selecting machining equipment should consider their industry characteristics and processing needs, and prioritize professional gantry machining center solutions to truly achieve cost reduction, efficiency improvement, and production upgrading.