Main Features:

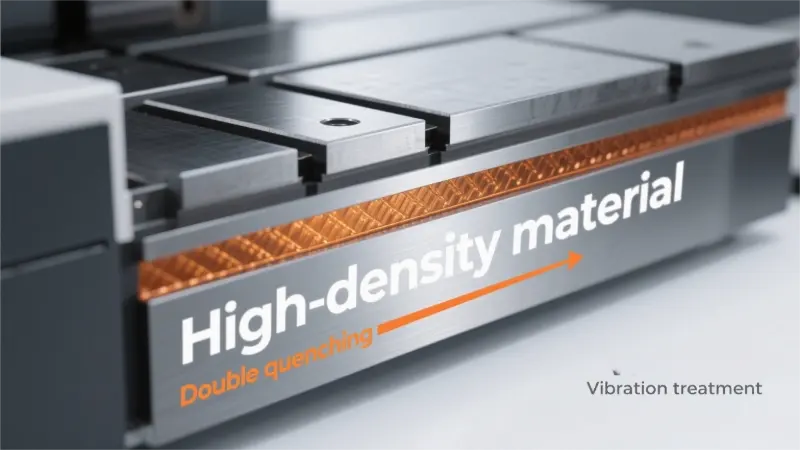

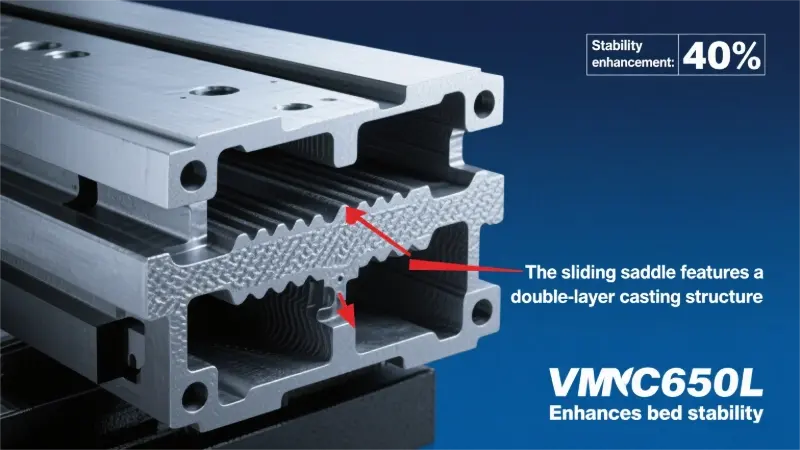

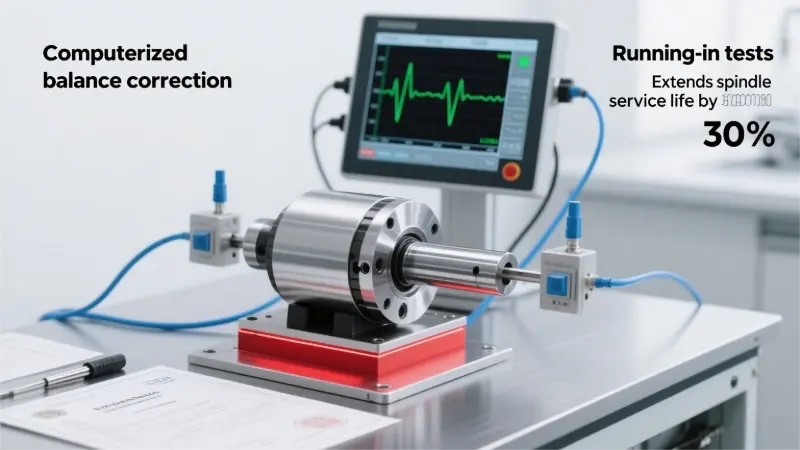

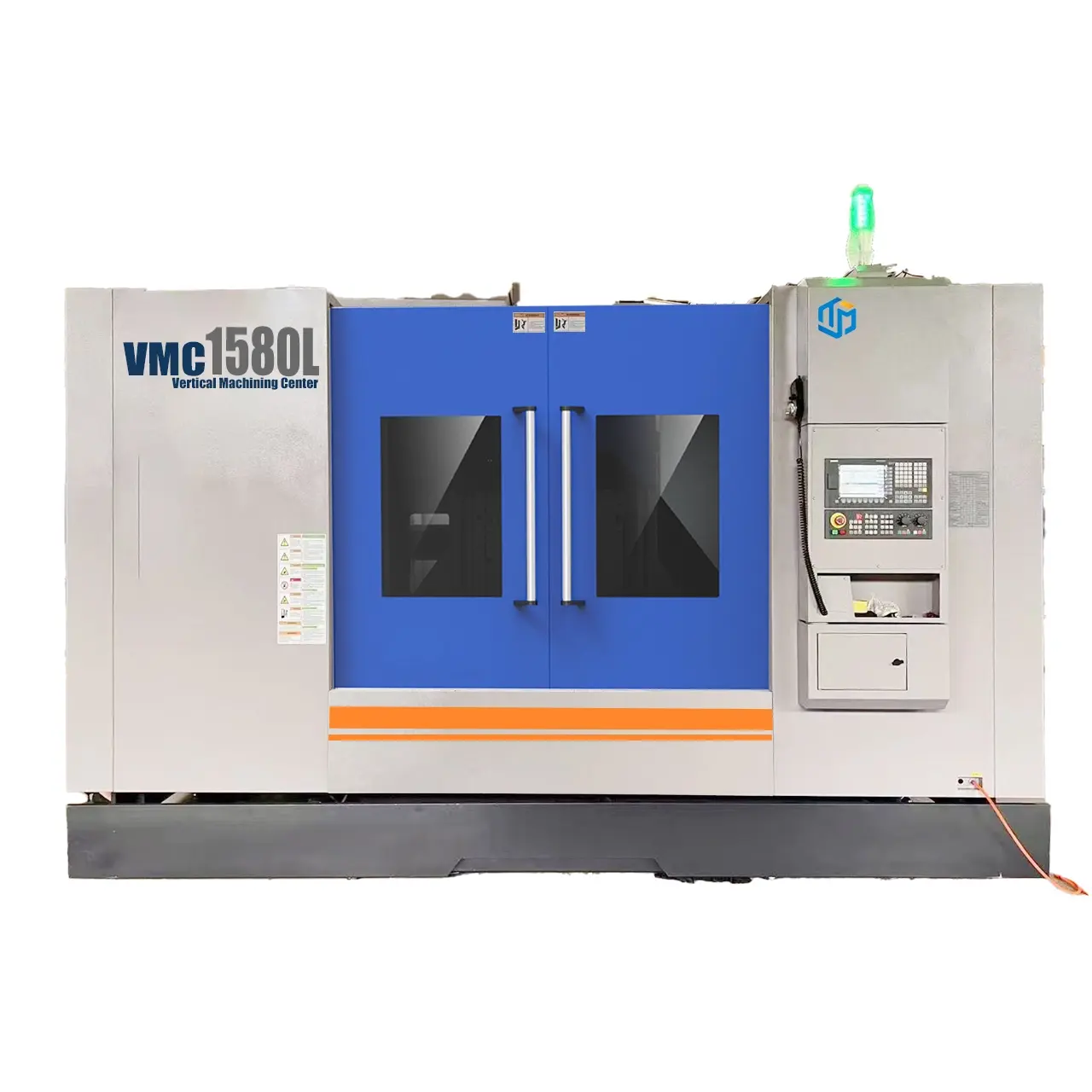

1. Boasts a sturdy structural design, enabling high-efficiency machining operations.

2. Comes with a built-in coolant system for stable temperature control during processing.

3. Equipped with a chip conveyor and purge mechanism, which guarantees optimal chip discharge performance.

4. Features a work table with excellent accessibility, facilitating convenient setup and tool installation.

5. Adopts an enclosed working area, effectively ensuring operational safety and preventing external contamination.