Widely used in mechanical processing, mold, instruments, instruments and other industries. The main components, such as base, fuselage, worktable, middle slide, lift slide and so on, are cast with high strength material, and the stability of machine tool is ensured by artificial aging

| specification | XL6436 |

| Worktable | \ |

| Table size(LxW) | 1325×360mm |

| Tslot(NxWxD | 3-18/80mm |

| Travel | \ |

| Table tavel (X/Y/Z) | 750×320×450mm |

| Tablefeed(X/Y/Z) | 30-750/20-500/15~375rpm |

| Swivel Table | ±45°Optional |

| Ram travel | 600mm |

| Spindle | \ |

| Spindle taper | 724 ISO50(HV) |

| Distance between spindle nose and table surface | 196-646mm |

| Spindle sped(12 steps) | 60-1750rpm(V) 60-1800pm(H) 12 steps 60-1750rpm(V) 12 steps 60-1800rpm(H) |

| Main motor power | 4kw(V),5.5kw(H) |

| Horizontal | \ |

| Distance between hoizontal nose and table suface | 20-470mm |

| Distance between horizontal nose and am surface | 200mm |

| Machine weight | \ |

| Max loading capacity | 350kg |

| N.w | 2650kg |

| 3phase ACfeeding servo motor torque | 10N.m |

| Overall size | \ |

| L×W×H | 1800×2100×2000mm |

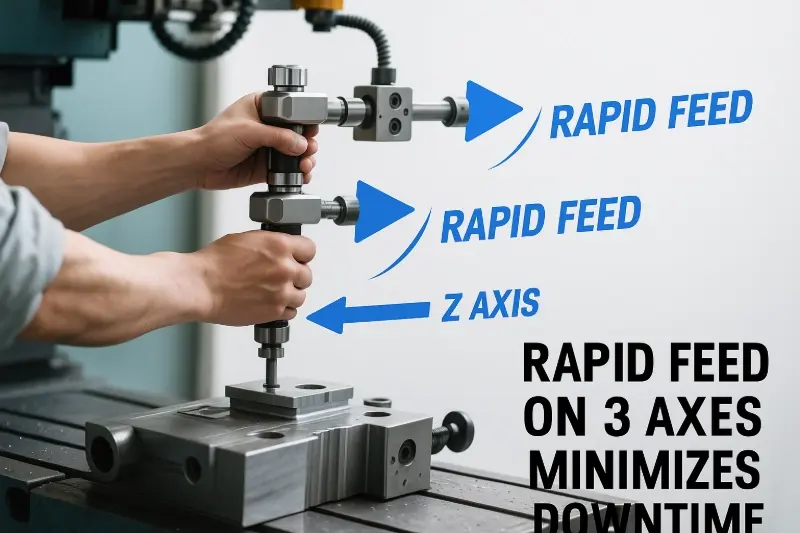

Finely graduated feeds in all axis, driven by servo motor

Complete with rapid feed in x-, y- and z-axis to reduce downtime

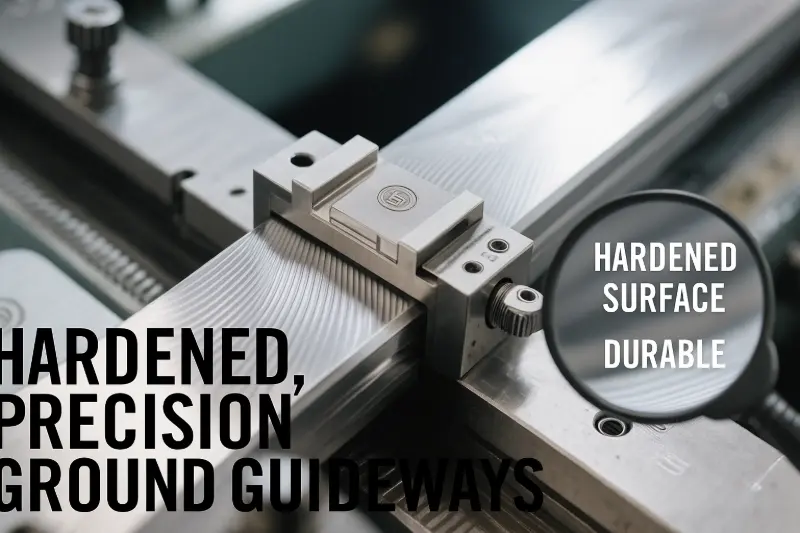

Precision-ground guide ways with hardened surfaces for long-term accuracy and wear-resistance