١. تماشيًا مع مفهوم التصميم القائم على الدفع عند مركز الثقل، زُوِّدت الآلة بثقل موازن مزدوج. في هذه الأثناء، يقع مركز الكبش على مركز المحور، مع توزيع متساوٍ لمسار الكبش. يمنع هذا التصميم انحناء مسار الكبش عند تحركه لأعلى ولأسفل. وبالتالي، يعمل المحور Z بثبات ودقة عاليين.

2. مجهزة بمبرد زيت ومصدر تبريد دورة لوحدة المغزل وكابينة المحرك.

3. مزودة بمبادل حراري، يمكن للخزانة الكهربائية استخلاص الحرارة بكفاءة أثناء العمل

4. يتم التحكم في محطة التشحيم بواسطة نظام CNC الذي يمكنه الاختبار والمعايرة تلقائيًا.

| مواصفة | جي ام سي 2230 |

| طاولة العمل | |

| حجم طاولة العمل (الطول × العرض) | 3000×2000 مم |

| حجم فتحات T (N×W×D) | 11-22×160 مم |

| يسافر | |

| حركة المحور X/Y/Z | 3200/2250/1000 مم |

| سعة | |

| المسافة من أنف المغزل إلى سطح طاولة العمل | 220-1220 ملم |

| المسافة بين عمودين | 2400 ملم |

| مغزل | |

| مخروط المغزل | بي تي 50 |

| قوة المغزل | 15/18.5 كيلو وات |

| أقصى سرعة للمغزل | 6000 دورة في الدقيقة |

| عزم دوران المغزل | 572 نيوتن متر |

| يٌطعم | |

| سرعة التغذية السريعة (X/Y/Z) | 10/10/10م/دقيقة |

| برغي كروي (القطر + الرصاص) | |

| برغي كروي محور X/Y/Z | 8020/6320/5016 |

| نوع المسار الإرشادي X/Y/Z | مسارات توجيه خطية X/Y: أسطوانة، مسار توجيه صندوقي Z: |

| مجلة الأدوات | |

| سعة مجلة الأدوات | 24 طنًا |

| الحد الأقصى لطول الأداة | 350 ملم |

| وقت تغيير الأداة (TT) | 3 ثوانٍ |

| دقة تحديد المواقع (المعيار البريطاني) | |

| دقة تحديد المواقع (X/Y/Z) | 0.03 ملم |

| دقة إعادة التموضع (X/Y/Z) | 0.018 ملم |

| أبعاد الماكينة | |

| الطول × العرض × الارتفاع | 8800×6400×5500 مم |

| وزن الماكينة | |

| أقصى تحميل لطاولة العمل | 12 طنًا |

| شمال غرب | 33.5 طن |

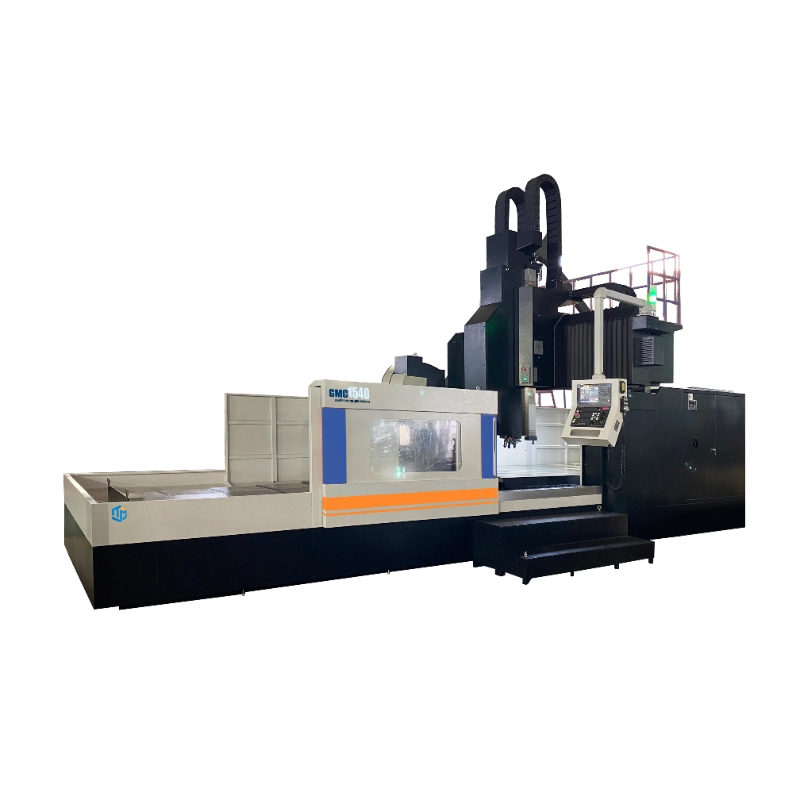

نطاق معالجة كبير، يتعامل بسهولة مع قطع العمل الكبيرة

بفضل هيكله الجسري الفريد، يتميز مركز تصنيع الآلات الجسري بمساحة استثنائية، مما يسمح بسهولة استيعاب ومعالجة مجموعة واسعة من قطع العمل الكبيرة والثقيلة. سواءً كانت مكونات كبيرة في صناعة الطيران، أو قطعًا ضخمة في بناء السفن، أو قوالب عملاقة في صناعة القوالب، فإنه قادر على التعامل مع هذه المهام بسهولة، موفرًا حلاً موثوقًا به للمعالجة المتكاملة لقطع العمل الكبيرة.

صلابة عالية واستقرار، مما يضمن الدقة

يوفر إطار القنطرية دعمًا متينًا لمركز التشغيل. يقلل هذا الهيكل المستقر الاهتزاز بفعالية أثناء القطع عالي السرعة أو الثقيل، مما يضمن دقة التشغيل. تلبي مراكز التشغيل القنطرية جميع متطلبات دقة الأبعاد، والتسطيح، وتفاوتات المواضع، مما يجعلها مناسبة بشكل خاص لتشغيل الأجزاء الدقيقة، مثل القوالب الكبيرة ومكونات الطائرات، والتي تتطلب دقة عالية للغاية.

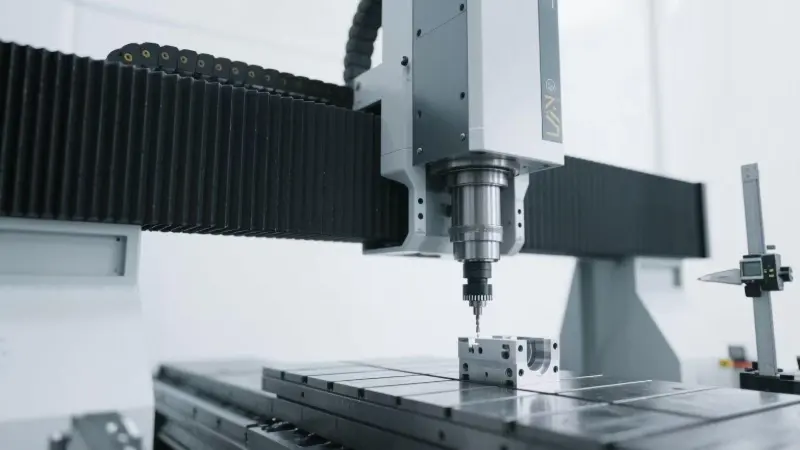

يتيح الربط متعدد المحاور تشغيل الآلات ذات الخطوط العريضة المعقدة

عادةً ما تكون مراكز التشغيل الجسرية مزودة بنظام ربط من 3 إلى 5 محاور، مما يسمح لها بإتمام عمليات تشغيل معقدة ذات محيط محدد، مثل الأسطح المنحنية والمائلة، بضغطة واحدة. تُقلل هذه القدرة على الربط متعدد المحاور من إعادة تثبيت قطعة العمل، وتُقلل من أخطاء التثبيت، وتُحسّن من ثبات التشغيل، مما يضمن كفاءة تشغيل الأجزاء المعقدة.

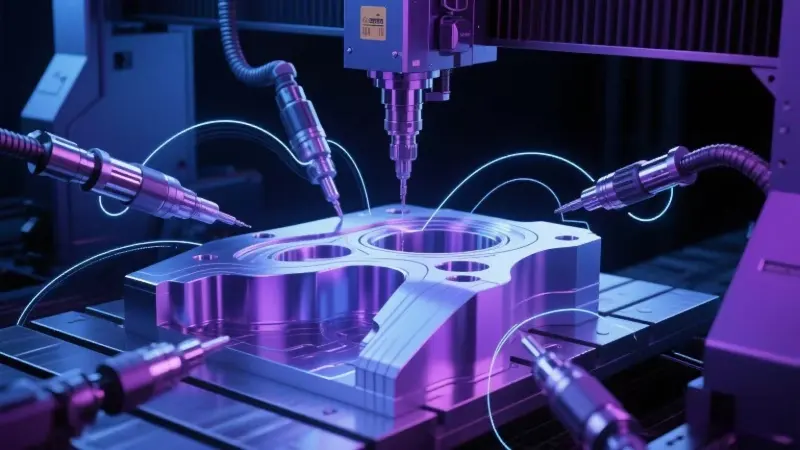

التشغيل الآلي الفعال وتحسين كفاءة الإنتاج

مراكز التشغيل الجسرية، المجهزة بمغزل عالي القدرة ونظام تغذية سريع، مناسبة للقطع الثقيل والإنتاج بكميات كبيرة. فهي قادرة على إزالة المواد بسرعة، وتقصير وقت التشغيل، وتحسين كفاءة التشغيل بشكل ملحوظ، مما يوفر دعمًا قويًا للإنتاج واسع النطاق.